We need to step back for a moment and think this through. Much of what you've done is in the right area, but you're spending money and time where it isn't doing any good. We need to diagnose the cause of this problem. The biggest part of that is understanding how these systems work.

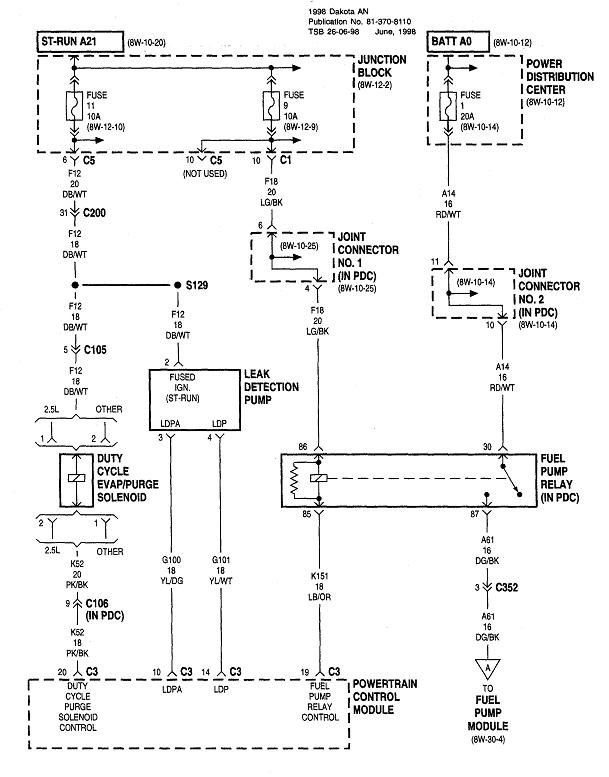

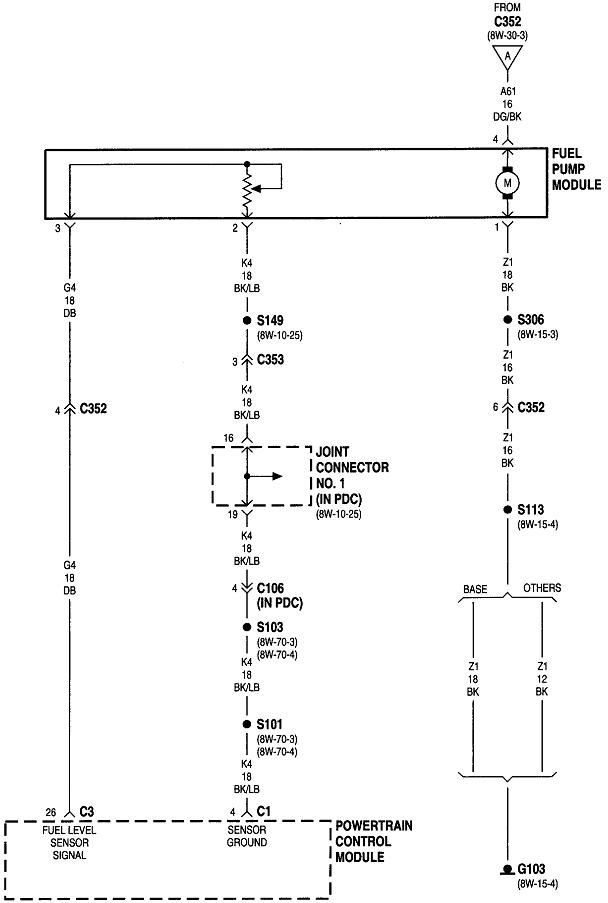

The first thing to be aware of is the fuel pump relay only gets turned on at two different times. The first is for one second right after you turn on the ignition switch. You may be able to hear the hum of the pump at that time. After that initial one second, the pump is turned off. That one-second burst is to insure fuel pressure is up for starting in case it bled down over days or weeks. If you put a fuel pressure gauge on the test port, you should find around 40 psi or more.

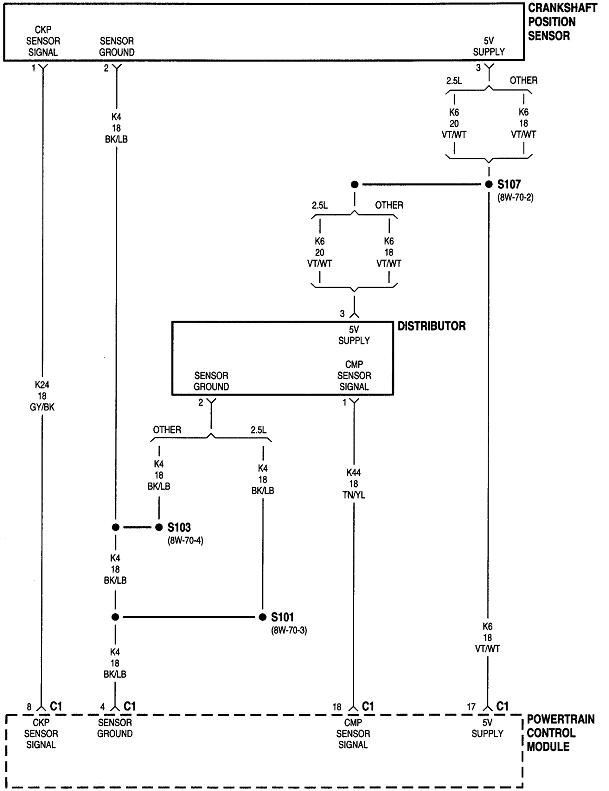

Next, the Engine Computer turns the fuel pump relay back on any time it sees engine rotation, (cranking or running). It knows that by the signal pulses it receives from the crankshaft position sensor and the camshaft position sensor.

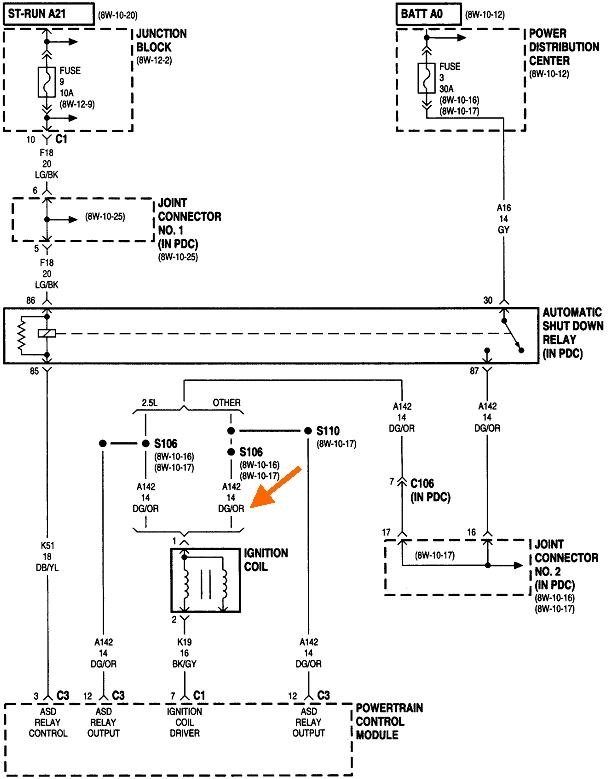

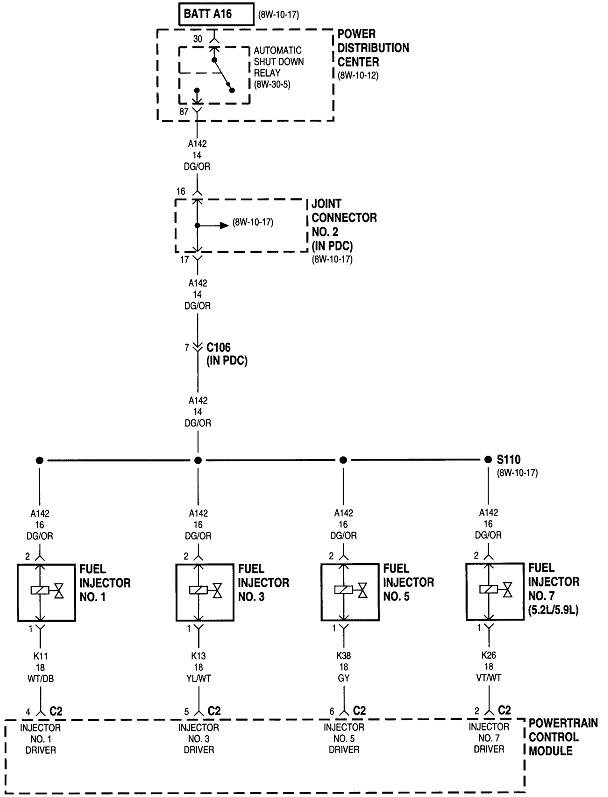

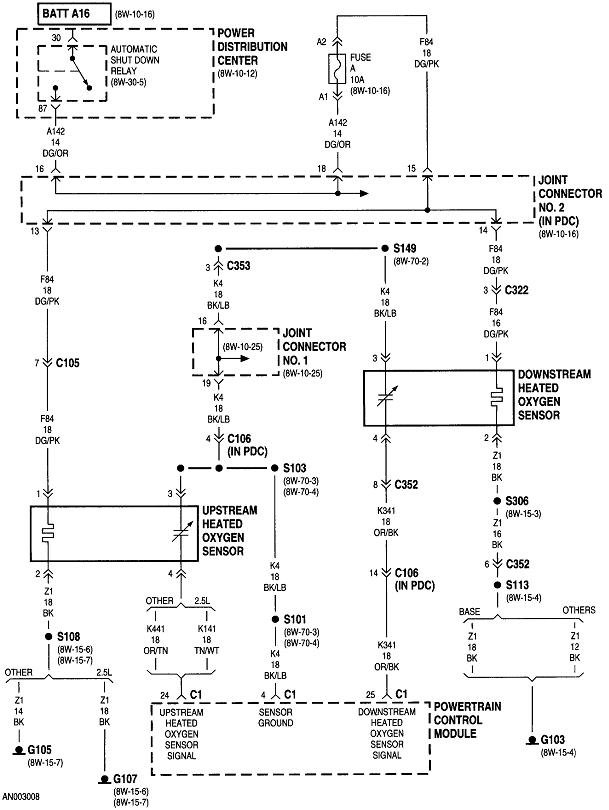

The Engine Computer also turns on the automatic shutdown, (ASD) relay at the same time it turns on the fuel pump relay. The ASD relay feeds the ignition coil(s), injectors, alternator field, oxygen sensor heaters, and a few other circuits. This circuit is the easiest one to use to check the operation of the cam and crank sensors. A test light works best for this next test. Digital voltmeters usually don't respond fast enough. For the benefit of others researching this topic who may need it, here's links to some articles on how to use a test light and voltmeter:

https://www.2carpros.com/articles/how-to-use-a-test-light-circuit-tester

https://www.2carpros.com/articles/how-to-use-a-voltmeter

Both tools can be found at Harbor Freight Tools, Walmart, or any hardware store. Test lights cost around three or four dollars. The little red voltmeter from Harbor Freight Tools only costs $7.00 and works perfectly fine.

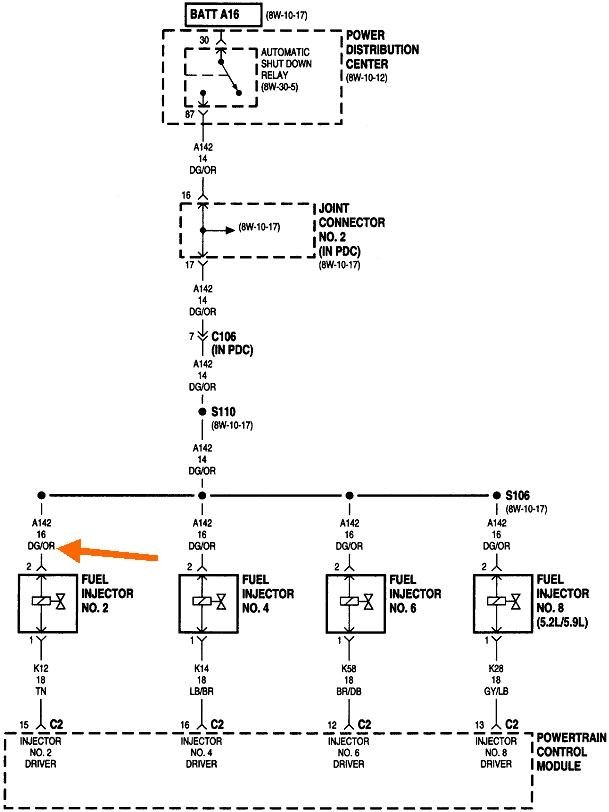

To check the operation of the ASD circuit, you can go to any of a number of places fed by that relay. The easiest may be the positive terminal on the ignition coil. You can also go to any injector and back-probe through the connector on the wire that is the same color at each of them. On most models that will be a dark green / orange wire. The orange arrow in the third diagram is pointing to that wire.

Don't worry if you don't know how to read these diagrams. I'm posting them in case we need them later. Connect your test light to that wire at the ignition coil or any injector. Have a helper run the ignition switch for you so you can watch the test light. You will see it light up for one second when the ignition switch is turned on. What's important is whether it turns back on when your helper starts cranking the engine.

Crank / no-start problems fall into one of three causes. About two percent are caused by a loss of spark only. Perhaps three percent are caused by a loss of fuel pressure only, almost always a fuel pump that didn't start up. At around 95 percent, by far most of these no-starts are caused by a loss of both spark and fuel pressure at the same time. That is caused by something both systems have in common, not by two individual failures. What they have in common is the ASD relay. If that relay turns on for the initial one second, that proves that circuit is okay, and the Engine Computer has control of it. If it turns back on during cranking, we have to diagnose either the ignition coil circuit or the fuel pump circuit. If the ASD relay doesn't turn back on during cranking, we have to look at the cam and crank sensors.

You already replaced the camshaft position sensor in the distributor, but that is only one part of the circuit. The best way to see if one of these circuits isn't generating its signal pulses is to view live data on a scanner. My Chrysler DRB3, for example, lists each sensor with a "No" or "Present" to show if the computer is seeing those signals. The one that stays on "No" during cranking is the circuit that has to be diagnosed.

Without a scanner, the only thing you can do is read the diagnostic fault codes and hope one is set for the failed circuit. The problem here is it takes the computer some time to detect the missing signal, as in when a stalled engine is coasting to a stop. Very often a fault code won't set just from cranking the engine. For that reason, don't assume the sensors are working if no related fault code is set.

You can use an inexpensive code reader, but Chrysler made reading fault codes in Engine Computers much easier than any other manufacturer. Cycle the ignition switch from "off" to "run" three times within five seconds without cranking the engine. Leave it in "run", then watch the code numbers appear in the odometer display. You can go here:

https://www.2carpros.com/trouble_codes/obd2

to see the definitions, or I can interpret them for you. It's important up to this point to not disconnect the battery or the Engine Computer as that will erase any fault codes, then that valuable information will be lost. Also be aware fault codes never tell you to replace a part or that one is bad. They only indicate the circuit or system that needs further diagnosis or the unacceptable operating condition. When a sensor or other part is referenced in a fault code, it is actually the cause of that code about half of the time. There are other tests we have to do on the entire circuit before replacing the part mentioned.

There are more diagrams for the Engine Computer, but these that I posted are the only ones related to this problem. Let me know what you find up to this point.

Images (Click to make bigger)

Thursday, September 30th, 2021 AT 7:36 PM