At this point a scanner is needed to see if the crank sensor's signal is showing up. If it is listed as the signal is there, another section typically includes a "no-start" menu with things to check that can cause this. The automatic shutdown, (ASD) relay is listed as being turned on or not during cranking. If it is, but there is still no spark, 12 volts may be not making it to the ignition coils. That 12-volt supply is the same one that feeds the injectors, so knowing where there is 12 volts and where there isn't will narrow the location of the break in that circuit.

It's more likely the crank sensor's signal will be missing during cranking. We know the ground and 12 volts are there, so that leaves the signal circuit, a defective new sensor, or a mechanical problem with that sensor. Unlike for some other sensor designs, the critical air gap for yours is set by the mounting bracket. The only thing that could happen is the new sensor isn't fully seated. That would make the air gap too big and no signal would be generated.

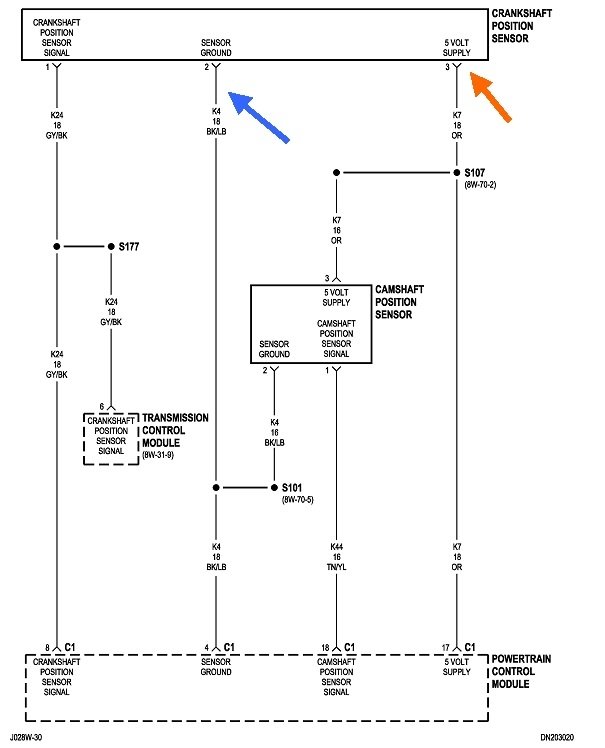

Assuming the new sensor is good and has 12 volts and ground, that leaves the gray / black signal wire. One test would be to back-probe that wire at the Engine Computer, terminal 8, and at the sensor, to see if you have the same voltages at both places. If they are different, there has to be a break in that wire.

Also notice the signal wire goes to the Transmission Computer Access that computer with the scanner and see if the crankshaft signal is showing up there during cranking. If it is, there has to be a break in that circuit between the splice and the Engine Computer.

Those are the only things that can cause a loss of signal for this sensor. If you don't have access to a scanner, you're limited to using a volt - ohm meter to check the signal wire for voltages and continuity.

Saturday, February 29th, 2020 AT 2:16 PM