To test the spark out. Leave the plug in it location and test with it's own wire. Test 2 plugs at the same time, here's the book on injector and ignition testing. INJECTOR CIRCUIT DIAGNOSIS 4.3L, 5.0L, 5.7L & 7.4L 1. Perform On-Board Diagnostic (OBD) system check. See ON-BOARD DIAGNOSTIC (OBD) SYSTEM CHECK in appropriate SELF-DIAGNOSTICS article. After performing OBD system check, go to next step. 2. Disconnect injector harness connector at intake manifold. Turn ignition on with engine off. Using a test light connected to ground, probe injector ignition feed circuits. See appropriate wiring diagram in WIRING DIAGRAMS article. If test light illuminates at all injector feed circuits, go to step 6. If test light does not illuminate at all injector feed circuits, go to next step. 3. If test light illuminates for only some of the injector circuits, go to step 5. If test light does not illuminate for any injector circuit, go to next step. 4. Check ECM I fuse (15-amp on 4.3L; 20-amp on all others), located in underhood fuse block. If fuse is open, go to step 10. If fuse is okay, go to step 11. 5. Locate open in faulty injector feed circuit. After locating faulty circuit, go to step 12. 6. Install injector test light to each injector circuit, one at a time. Crank engine. If injector test light flashes on each injector, check fuel injector(s). See FUEL SYSTEM in appropriate SYSTEM & COMPONENT TESTING article. If injector test light does not flash for each injector circuit, go to next step. 7. If injector test light was on steady on any injector circuit, go to next step. If injector test light did not illuminate on any injector circuit, go to step 9. 8. Install injector test light to faulty injector circuit. Turn ignition off. Disconnect Red VCM harness connector. Turn ignition on with engine off. If injector test light is off, go to step 16. If injector test light remains illuminated, go to step 13. 9. Check for an open in injector control circuit. If circuit is open, go to step 12. If circuit is okay, go to step 14. 10. Locate short to ground in injector control circuit. After locating short, go to step 12. 11. Repair open or short to ground for all injector feed circuits. After repairs, go to step 17. 12. Repair circuit as necessary. After repairs, go to step 17. 13. Repair short to ground in injector control circuit. After repairs, go to step 17. 14. Check terminal contact at VCM harness connector. If terminal contact is faulty, go to next step. If terminal contact is okay, go to step 16. 15. Repair terminal contact as necessary. After repairs, go to step 17. 16. Replace VCM. Perform VCM reprogramming procedures. After repairs, go to next step. 17. Using scan tool, select DTC, CLEAR INFO function. Attempt to start engine. If engine starts and continues to run, go to next step. If engine does not start, or starts and stalls, go to step 2. 18. Allow engine to reach normal operating temperature. Using scan tool, select DTC, FAILED THIS IGN function. If any other DTCs are present, diagnose DTCs. See appropriate SELF- DIAGNOSTICS article. If no other DTCs are present, go to next step. 19. Using scan tool, select CAPTURE INFO, REVIEW INFO function. If additional undiagnosed DTCs are present, diagnose DTCs. See appropriate SELF-DIAGNOSTICS article. If additional NOTE: This test only applies to vehicles equipped with a VCM. DTCs are not present, system is okay.

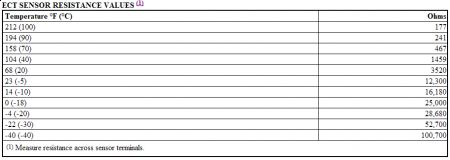

NO START-ENGINE CRANKS OKAY (4.3L, 5.0L, 5.7L & 7.4L) General Inspection 1. Ensure proper starting procedure is being used. Visually check vacuum hoses for splits, kinks and proper connections, as shown on Vehicle Emission Control Information label. Check ignition wires for cracking, hardness and proper connections at both coil pack and spark plugs. 2. Remove spark plugs. Check and replace as necessary. In very cold temperatures, ensure oil is proper viscosity and not contaminated with gasoline. Ignition System 1. Perform On-Board Diagnostic (OBD) system check. See ON-BOARD DIAGNOSTIC (OBD) SYSTEM CHECK in appropriate SELF-DIAGNOSTICS article. After performing OBD system check, go to next step. 2. Attempt to start engine. If engine starts and continues to run, see appropriate TROUBLE SHOOTING - NO CODES article. If engine does not start, go to next step. 3. For "P" series, go to next step. On all models except "P" series, install scan tool. Monitor VTD FUEL DISABLED parameter while cranking engine. If VTD FUEL DISABLED parameter is active while cranking engine, diagnose anti-theft system. See appropriate ANTI-THEFT SYSTEMS article in ACCESSORIES & EQUIPMENT. If VTD FUEL DISABLED parameter is not active while cranking engine, go to next step. 4. Using scan tool, monitor Throttle Position (TP) sensor voltage with throttle closed. If TP sensor voltage is greater than 2.5 volts, go to DTC P0121. See appropriate SELF- DIAGNOSTICS article. If TP sensor voltage is 2.5 volts or less, go to next step. 5. Using scan tool, monitor Engine Coolant Temperature (ECT) sensor. If ECT sensor value is less than -22 °F (-30 °C), go to DTC P0118. See appropriate SELF-DIAGNOSTICS article. If ECT sensor value is -22 °F (-30 °C) or greater, go to next step. 6. Using Spark Tester (J-26792), check for spark at 2 spark plug wires while cranking engine. If spark is present at both wires, go to next step. If spark is not present at both wires, diagnose components and power, ground and signal circuits related to ignition system. See appropriate wiring diagram in WIRING DIAGRAMS article. Also see BASIC IGNITION SYSTEM CHECKS. Repair as necessary. 7. Turn ignition off. Reconnect spark plug wires. Connect fuel pressure gauge. Turn ignition on with engine off. Observe fuel pressure. If fuel pressure is 55-60 psi (3.9-4.3 kg/cm 2 ), go to next step. If fuel pressure is not as specified, diagnose fuel system. See BASIC FUEL SYSTEM CHECKS (GASOLINE ENGINES). 8. Turn ignition off. Disconnect fuel injector harness connector at intake manifold. Using a test NOTE: Before performing the following tests, check battery condition, engine cranking speed and for adequate fuel in tank. NOTE: VCM data is deleted when using scan tool CLEAR INFO function. Before clearing DTCs, use scan tool CAPTURE INFO function to record FREEZE FRAME and FAILURE RECORDS data. Light connected to ground, probe each fuel injector feed circuit while cranking engine. See appropriate wiring diagram in WIRING DIAGRAMS article. If test light illuminates for each circuit, perform fuel injector coil test. See FUEL SYSTEM (GASOLINE) in appropriate SYSTEM & COMPONENT TESTING article. Also, check for any engine mechanical problems. Repair as necessary. If test light does not illuminate, diagnose fuel injector circuit. See FUEL SYSTEM (GASOLINE) in appropriate SYSTEM & COMPONENT TESTING article.

1/19/2010 .

Tuesday, January 19th, 2010 AT 6:19 PM