Hello, thanks for the donation much appreciated.

All models are equipped with the ELC you would have to check whether your model has CVRSS. I have enclosed a description and a couple of test's to carry out. hope this helps. let me know.

DESCRIPTION

NOTE:This article covers models equipped with Electronic Level Control (ELC) as a stand-alone system. For information on models that are equipped with both ELC and Continuously Variable Road-Sensing Suspension (CVRSS), see ELECTRONIC - LEVEL CONTROL - CADILLAC WITH CVRSS article.

Electronic Level Control (ELC) system automatically raises or lowers rear of vehicle to correct ride height (curb height), compensating for load added to or removed from vehicle. System consists of a compressor, air drier, exhaust solenoid, ELC relay, height sensor, air adjustable struts, pressure limiter and connecting air lines.

SYSTEM OPERATION

When ride height decreases due to weight being added to vehicle, height sensor arm assembly rotates upward in relation to height sensor. See Fig. 1 . This activates a timing circuit in height sensor. After a delay of about 13-27 seconds, height sensor grounds ELC relay, turning on compressor. Air is then pumped into struts, raising vehicle. Delay prevents system from operating during normal changes in ride height that occur during driving. As vehicle rises, height sensor rotates downward. When vehicle rises to within one inch (25.4 mm) of curb height, height sensor opens ground circuit to ELC relay, turning compressor off.

When ride height increases due to weight being removed from vehicle, height sensor arm assembly rotates downward. This activates the timing circuit in height sensor. After a delay of about 13-27 seconds, height sensor grounds exhaust solenoid valve circuit, causing air to be vented from struts, lowering vehicle. When vehicle has lowered to within one inch (25.4 mm) of curb height, height sensor opens exhaust solenoid valve circuit, causing exhaust solenoid valve to close.

To ensure system is operating with at least minimum air pressure, height sensor commands an air replenishment cycle each time ignition is turned on. An internal timer circuit is activated when ignition is turned on. After a delay of about 35-45 seconds, compressor turns on for 3-5 seconds to ensure residual system pressure exists. If weight is added to or removed from vehicle during 35-45 second delay, air replenishment cycle will be overridden and vehicle will rise or lower after normal time delay.

Voltage is applied to compressor, ELC relay, inflator timer and height sensor at all times. This allows system to vent if load is removed with ignition off. Height sensor limits compressor operation or exhaust solenoid energized time to 7 minutes. Time limit is necessary to prevent continuous compressor operation in case of air leak. Turning ignition switch from OFF to ON position resets compressor operation or exhaust solenoid valve energized time.

COMPONENT OPERATION

Air Adjustable Struts

Air adjustable strut is a conventional strut enclosed in an air chamber, which extends when air pressure is increased in chamber.

Air Drier

Air drier, attached to compressor output, absorbs moisture from air being delivered to air adjustable struts. Air drier contains a valve that maintains a minimum air pressure of 7-14 psi (.49-.98 kg/cm2 ) in struts.

Compressor

Compressor, located on right rear suspension support, provides air pressure for system operation. Compressor head casting contains intake and exhaust valves, and exhaust solenoid valve.

ELC Relay

ELC relay is located in trunk, below center of rear shelf. When ELC relay is grounded by height sensor, voltage is supplied to compressor.

Exhaust Solenoid Valve

Exhaust solenoid valve, located in compressor head assembly, exhausts air from the system and limits compressor output pressure.

Height Sensor

Height sensor, mounted to rear underbody frame, links body to left rear suspension arm. Sensor controls ground circuits of ELC relay and exhaust solenoid valve.

ADJUSTMENTS

HEIGHT SENSOR

Park vehicle on level surface. Ensure fuel tank is full and vehicle is unloaded. If necessary, simulate full tank by adding appropriate amount of weight to vehicle (about 7 lbs. for every gallon less than full). Ensure tire inflation pressure is correct. Move front seat rearward. Turn ignition on to activate ELC system. Bounce rear of vehicle 3 times to normalize suspension.

Measure rear ride height. See REAR RIDE HEIGHT . If rear ride height varies by more than 1/2" (12 mm) from side to side, or is lower than specified, repair suspension problem before continuing procedure. If ride height is as specified, height sensor is adjusted.

NOTE:Height sensor arm assembly can be moved a total of 5 degrees. One degree of change at height sensor arm assembly results in a 1/4" (6 mm) change in height at rear bumper.

If rear ride height is not within specification, loosen lock bolt on sensor arm. See Fig. 1 . To increase ride height, move plastic arm upward. To decrease ride height, move plastic arm downward. Tighten lock nut.

Fig. 1: Adjusting Height Sensor

REAR RIDE HEIGHT

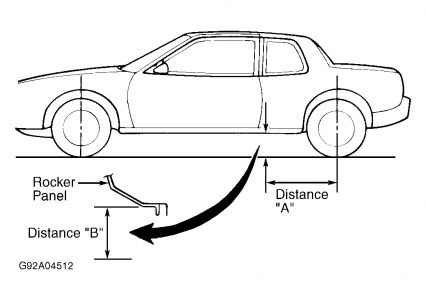

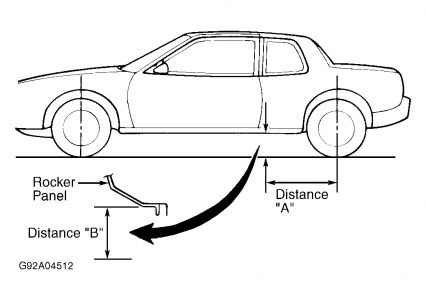

Mark a spot on bottom of rocker panel, 22 3/16" (563 mm) forward of rear axle center line (distance "A"). See Fig. 2 . Measure distance between marked spot and ground (distance "B"). If vehicle is on hoist, consider ground line to be horizontal line between bottom of front and rear tires. Distance "B" should be 7 9/16 - 8 11/32" (192-212 mm).

DESCRIPTION

NOTE:Models are also equipped with Continuously Variable Road-Sensing Suspension (CVRSS). For information on CVRSS, see ELECTRONIC - CV ROAD-SENSING - CADILLAC article.

Electronic Level Control (ELC) system automatically raises or lowers rear of vehicle to correct riding height (curb height), compensating for load added to or removed from vehicle. System consists of an air compressor, air drier, exhaust solenoid valve, compressor relay, 2 position sensors, air adjustable rear shock absorbers, Road-Sensing Suspension (RSS) control module, and connecting air lines. ELC air compressor is controlled by RSS control module.

NOTE:All models are also equipped with Electronic Level Control (ELC). For information on ELC system, see ELECTRONIC - LEVEL CONTROL - CADILLAC WITH CVRSS article.

Continuously Variable Road-Sensing Suspension (CVRSS) system performs 2 functions:

Controls firmness of vehicle ride (this part of the system is called CVRSS, although the term CVRSS is also applied to the entire system.

Adjusts vehicle riding height (this part of the system is called Electronic Level Control, or ELC).

CVRSS control module monitors system for faults. If a fault occurs, codes are stored in memory. See SELF-DIAGNOSTICS under DIAGNOSIS & TESTING. Self-diagnostics also allows technician to monitor CVRSS system data, inputs and outputs.

CONTINUOUSLY VARIABLE ROAD-SENSING SUSPENSION (CVRSS)

Continuously Variable Road-Sensing Suspension (CVRSS) system can change firmness of vehicle ride in 10 milliseconds. Vehicle ride firmness is determined by how easily the strut or shock absorber can be compressed (damping characteristics). In each strut and shock absorber, damper oil flows through a damper that has 2 different sized orifices, one for firm mode and the other for soft mode. A damper actuator rotates the damper between positions (modes). Damper actuator is an integral part of strut and is not serviceable separately from strut. Damper actuators respond to command signals from CVRSS control module. CVRSS control module command signals are based on the following inputs.

Thursday, January 29th, 2009 AT 5:00 AM