Wednesday, May 31st, 2017 AT 7:16 PM

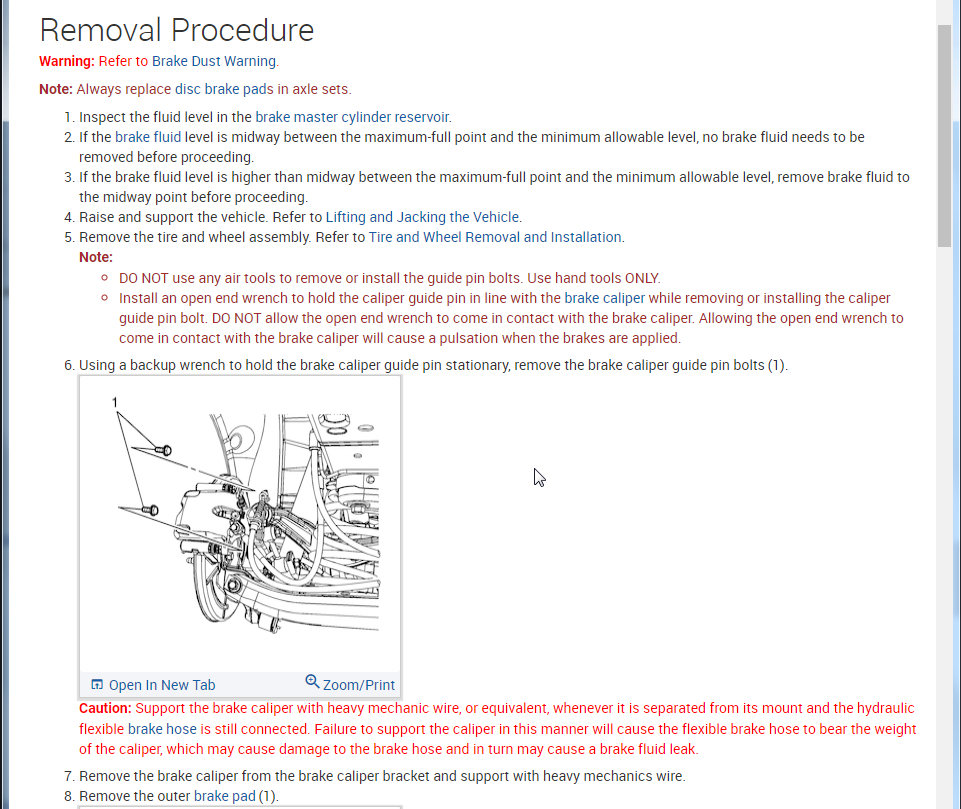

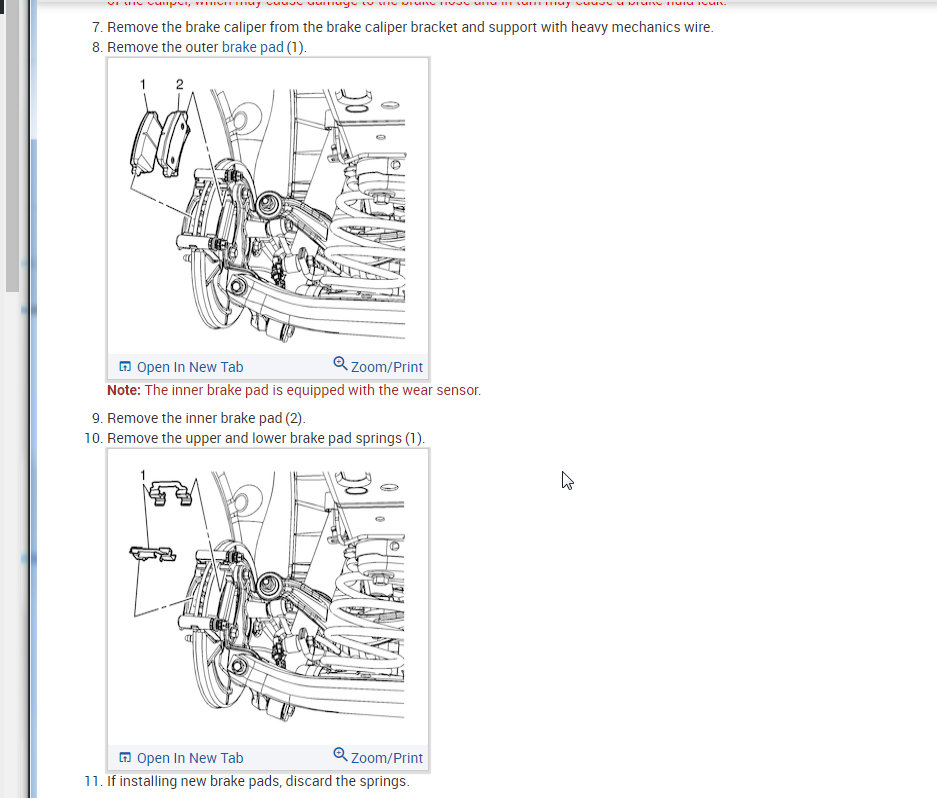

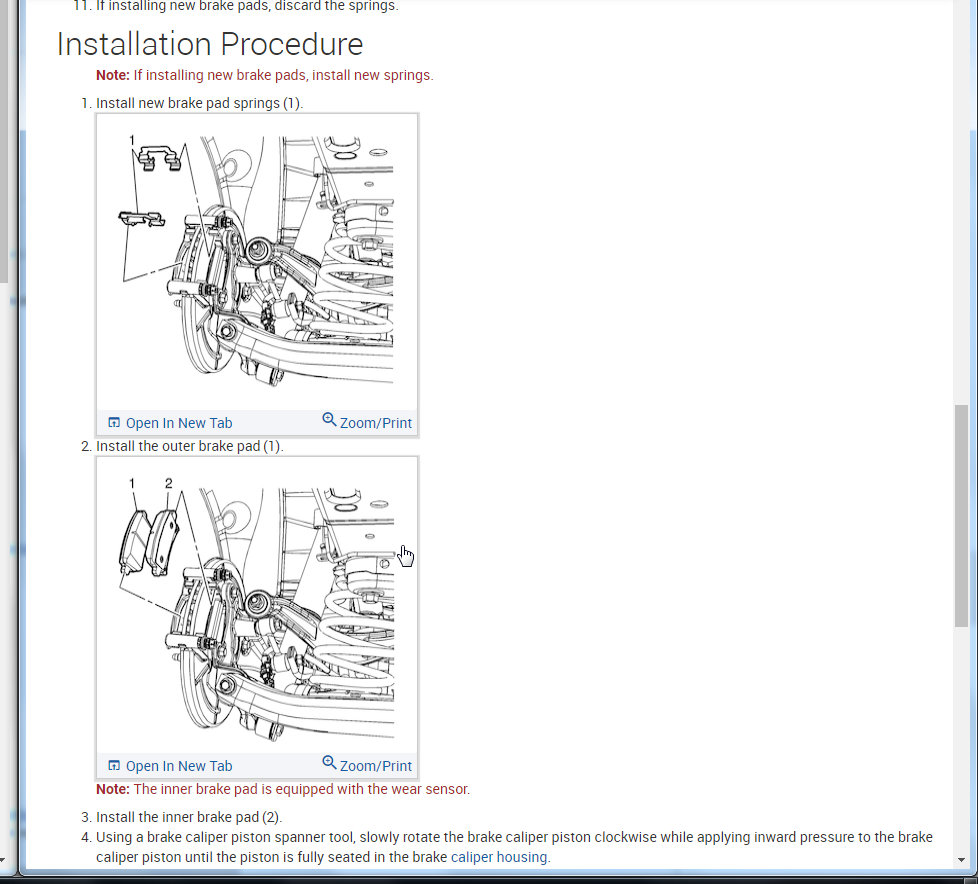

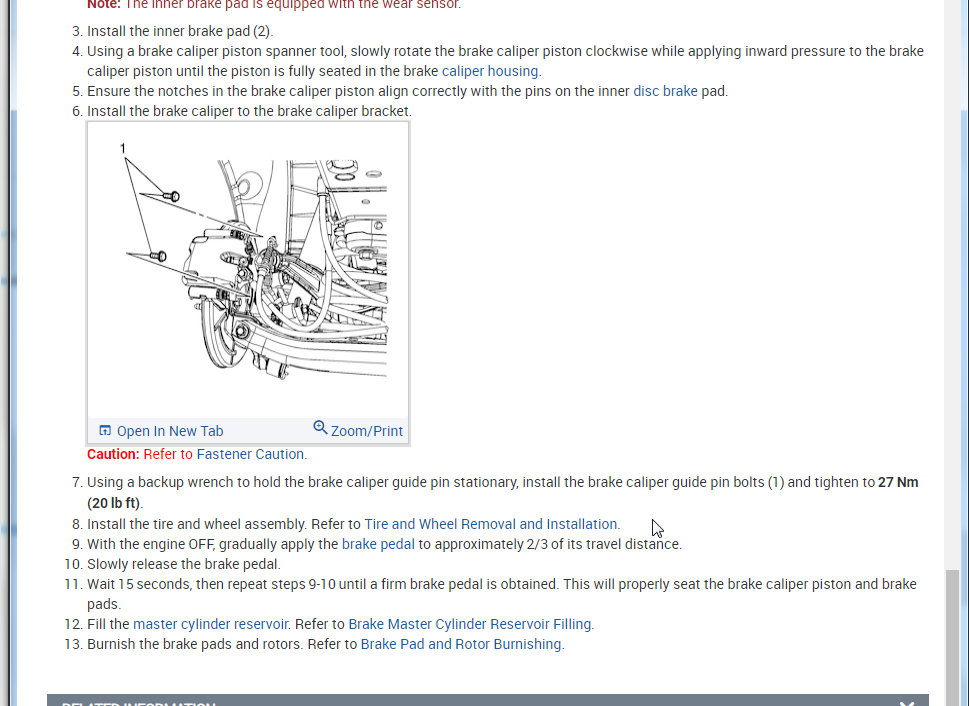

Stability track and service brake assist light came on yesterday. Stopped car, turned back on. Light was out. Then I heard the brake grinding in the rear.