P0522 - Engine Oil Pressure Sensor/Switch Circuit Low Voltage

There's three things that can cause this code. The least likely is the sensor itself, but that was a good guess to start.

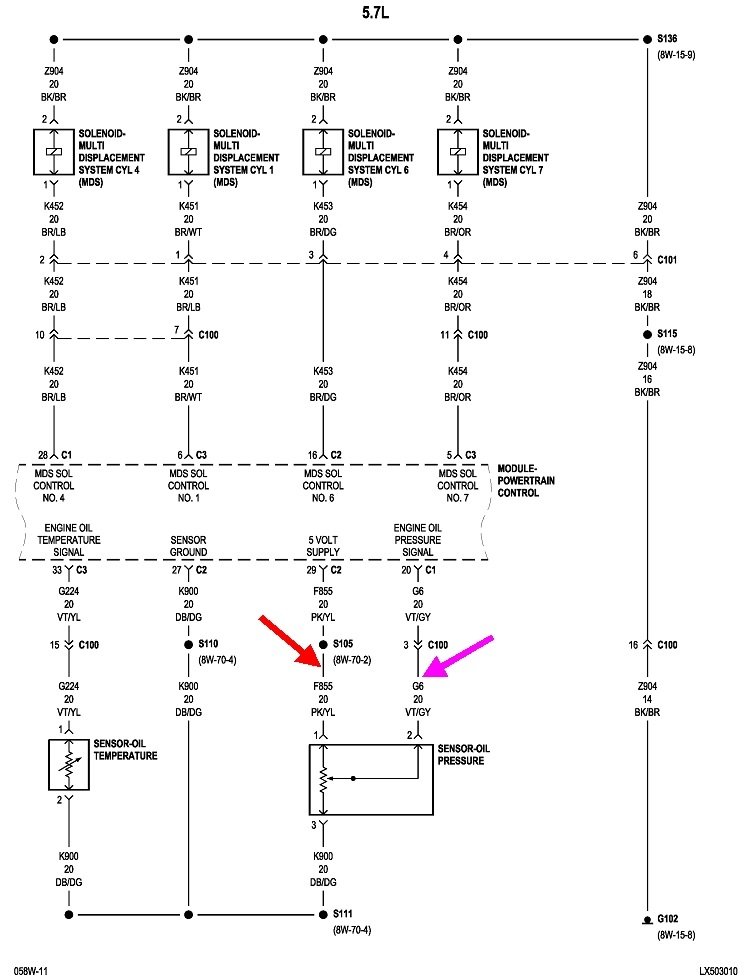

This diagram shows the oil pressure sensor circuit. The red arrow is pointing to the pink / yellow wire which is the 5.0-volt feed for the sensor. If that wire has a break in it, everything related to that sensor will have 0 volts on it. For most sensors of this type, they're fed with 5.0 volts and ground, then the signal circuit picks a point in between them to report back to the computer. The clinker is though, there are in effect, mechanical stops that limit the range of signal voltage to approximately 0.5 volts to 4.5 volts. The only way the signal wire can ever reach 0.0 or 5.0 volts is when there's a defect in the sensor or its wiring, and that is how the computer detects those defects and sets the appropriate diagnostic fault code.

In this case, less than 0.5 volts is being reported by the oil pressure sensor, and that is setting the fault code, "voltage too low". It's important to note that code does not say the sensor is defective or needs to be replaced. Fault codes never say to replace a part. They only indicate the circuit or system that needs further diagnosis, or the unacceptable operating condition.

We don't even have to discuss the sensor itself since you already tried that. There's two more ways this code can be set. Besides the cut pink / yellow wire, the violet / gray signal wire could be shorted to ground. Common causes would include the wire harness fell down onto the sharp edge of a metal bracket and the insulation rubbed through, or the harness is sliding back and forth on the inner fender as the engine rocks back and forth between acceleration and coasting, then the paint and insulation rubbed through.

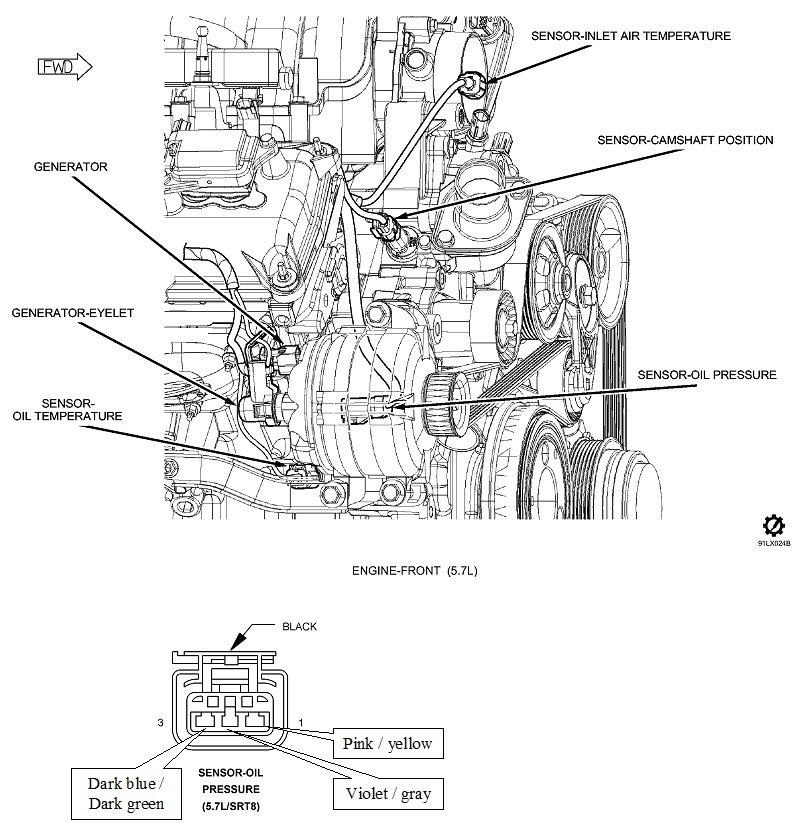

The place to start is with some voltage tests. Turn the ignition switch to "run", unplug the oil pressure sensor, then measure the voltages on the two wires I have arrows pointing to. The pink / yellow should have 5.0 volts. If it doesn't, that wire has a break in it. Corroded splices are always good suspects. This circuit has one in it, splice "S105".

To add to the confusion, you should find 5.0 volts on the violet / gray wire too, but only when the plug is disconnected. You won't be tested on this later, but this is done by adding a "pull-up" resistor inside the computer between this signal wire and its internal 5.0-volt supply. Under normal operation, this resistor is so huge electrically that it's like it's not even there. It's only when that signal wire is broken that due to all of the interconnected circuitry inside the computer, that signal voltage could "float" to some random value. Even though that voltage has no valid meaning, as long as it stays within 0.5 to 4.5 volts, the computer will accept it and try to run the engine on that. The pull-up resistor now comes into play and puts 5.0 volts on the signal wire to force the computer to detect the defective condition.

This same pull-up resistor is used for all computer sensor signal circuits, but the same thing can be done with a "pull-down" resistor. Those are tied between the signal wire and ground, inside the computer. Again, it is done to force the computer to detect a defective condition. It seems you'll find pull-down resistors much more often on import car models, but they could be used on any car model. Regardless whether a pull-up or a pull-down resistor is used, the voltage it puts on a signal wire is easily overcome by the sensor's signal voltage when the circuit gets back to working properly.

One quick clue to finding this defect is to reread the diagnostic fault codes right after you unplug the sensor. Remember, the pink / yellow wire could be "open", meaning cut / broken, or the violet / gray wire could be grounded. Either condition will set this fault code. When you unplug the sensor, if the violet / gray circuit is okay, the pull-up resistor is going to put 5.0 volts on it, and now you'll have an additional fault code for "signal voltage too high". That can't happen if that signal wire is grounded, so that just leaves the 5.0-volt supply wire as the suspect.

If you find 0.0 volts on the signal wire when the sensor is unplugged, switch to a continuity test with your ohm meter and measure the resistance of that wire to a clean, paint-free place on the engine or body sheet metal. You should find very high resistance, in the order of meg ohms, (million ohms), or an open circuit, (infinite or "over-range" reading on the meter). If that wire is grounded, the resistance will be close to 0 ohms. There's always some resistance in the meter's leads, and often there's a little resistance in whatever is shorted, so you could even find a few dozen ohms of resistance. The point is it should be a very high reading.

Here's a link to an article about using a volt / ohm meter if you need it:

https://www.2carpros.com/articles/how-to-use-a-voltmeter

They're using a rather expensive meter with the "auto-ranging" feature. Those can be confusing if you fail to observe which range the meter selected for you. You can find a perfectly fine standard meter at places like Harbor Freight Tools for around $7.00. I can help you with setting it up if necessary.

Images (Click to make bigger)

Monday, December 28th, 2020 AT 7:00 PM