There is a Bulletin for a vacuum leak but list's trouble code's which you said you don't have and also doesn't mention a whistling.I have never heard a whistling to go with that bulletin. Your best bet is to spray some carb around vacuum point's and listen for a change in the way the engine run's.You can clearly tell you have a problem because a lot of the intake manifold vacuum chamber bolts are loose.Let me know what you find.

Here is a guide that may help as well

https://www.2carpros.com/articles/how-to-use-an-engine-vacuum-gauge

File in Section: 06 - Engine/Propulsion System

Bulletin No.: 02-06-01-016A

Issue Date: March, 2003

Subject:

(MIL) SERVICE ENGINE SOON Telltale Illuminated With DTCS P0171 and/or P0174 (Retorque Intake Manifold Vacuum Chamber Bolts, Install Vacuum Chamber Springs)

Models Affected:

2002-2003 Saturn VUE - built up to and including VIN breakpoint 3S854417 with 3.0L, V6 engine (VIN R - RPO L81)

Attention: Technician

This bulletin is being revised due to a change in Parts Requirements. Please discard bulletin 02-T-28 (Corporate Bulletin Number 02-06-01-016, Section 06 - Engine).

Condition:

Some customers may comment on the (MIL) SERVICE ENGINE SOON telltale being illuminated. (DTC(s) P0171 - Fuel Trim System Lean Bank 1 and/or DTC P0174 - Fuel Trim System Lean Bank 2 may be set and stored in the ECM memory.)

Cause:

This condition may be caused by insufficient torque on the intake manifold vacuum chamber bolts. Under deceleration, enough vacuum can be created inside the intake manifold to lift the vacuum chamber off it's seal creating an intermittent vacuum leak.

Correction:

Refer to the service procedure in this bulletin to retorque the intake manifold vacuum chamber bolts and install the vacuum chamber springs.

Procedure:

Notice: When servicing intake manifold, do not use power tools. Damage to threads or manifold may occur.

1. Loosen clamp at air cleaner assembly and throttle body assembly.

2. Remove attachment bolts from outlet resonator/duct assembly.

3. Remove outlet resonator/duct assembly.

4. Remove outlet resonator/duct assembly bracket from manifold.

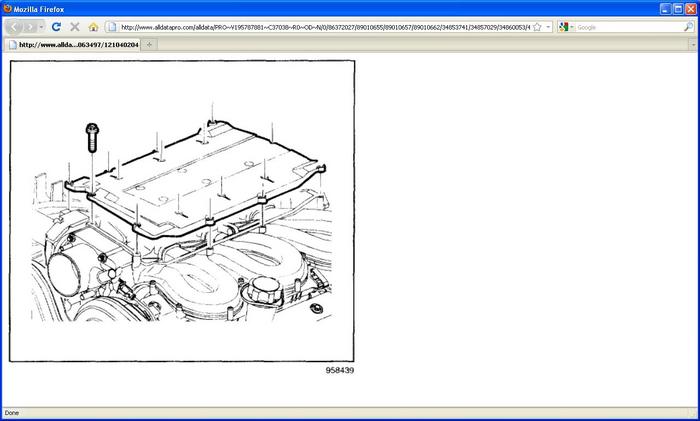

5. Remove 16 (10 around outside, 6 on inside) intake manifold top cover bolts and cover.

6. Remove vacuum chamber and apply Loctite(TM) 242, P/N 21485277 (in Canada, P/N 12345382), or equivalent, to the bolts and reinstall.

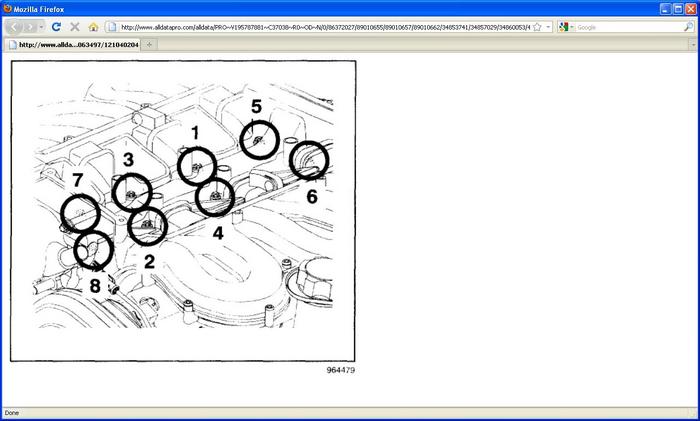

7. Torque vacuum chamber bolts according to torque sequence shown.

Torque

2.5 N.m (22 in-lbs).

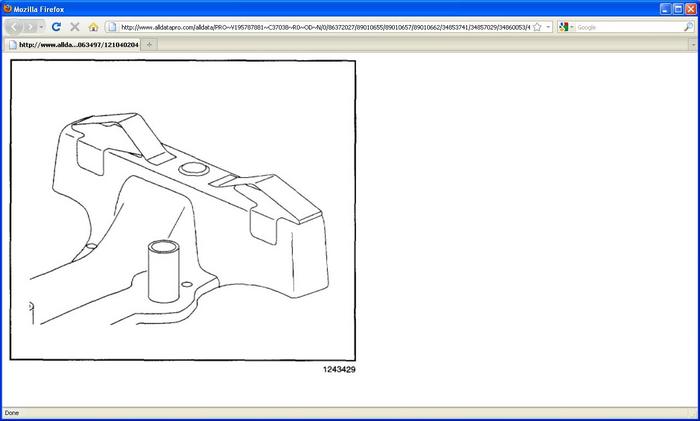

8. Install vacuum chamber springs, P/N 93175463, on vacuum chamber as shown.

9. Ensure sleeve seals are in position on manifold top cover and install cover into position.

10. Apply Loctite(TM) 242, P/N 21485277 (in Canada, P/N 12345382), or equivalent, to all 16 top cover bolts and hand start.

11. Torque 10 bolts around outside of cover as shown.

Torque

10 Outside Intake Manifold To Cover-to-Manifold Bolts 4 N.m (35 in-lbs).

12. Torque 6 bolts on inside of cover as shown.

Torque

6 Inside Intake Manifold Top Cover-to-Manifold Bolts: 4.4 N.m 39 (in-lbs).

13. Install outlet resonator/duct assembly bracket to intake manifold.

Torque

Outlet Resonator/Duct Assembly Bracket-to-Intake Manifold Nuts: 5 N.m (44 in-lbs).

14. Install outlet resonator/duct assembly into position.

15. Tighten clamp at throttle body assembly.

16. Position outlet resonator/duct assembly to support bracket and install bolts.

Torque

Outlet Resonator/Duct Assembly to support Bracket Bolts: 10 N.m (89 in-lbs).

17. Tighten clamp at air cleaner assembly.

18. Verify Repair as follows:

Connect Scan Tool to the vehicle.

Navigate to the 3.0L (VIN B) menu.

Select DIAGNOSTIC TROUBLE CODES (DTC).

Select CLEAR DTC INFORMATION, this will zero the short and long term fuel trim information.

Navigate to the Powertrain Menu and Select DATA DISPLAY.

Select ENGINE DATA DISPLA.

Select FUEL AND EMISSIONS.

19. Monitor the following data:

Short Term FT Bank 1

Short Term FT Bank 2

20. Start the engine, the Short Term FT will remain at 0% until the vehicle enters closed loop operation (approximately 5 seconds). Does the Short Term FT Bank 1 or 2 exceed 5% during the first 10 seconds of closed loop operation? (After 10 seconds, the Short Term FT readings can be affected by EVAP canister purge vapors).

If yes, there is still a lean condition present, refer to DIAGNOSTIC AIDS for P0171/P0174 in the 2002-2003 VUE Powertrain Electrical Diagnostics Service Manual.

If no, vehicle is repaired.

Parts Requirements

Claim Information:

To receive credit for this repair during the warranty coverage period, submit a claim through the Saturn Dealer System for J5520 (Inlet Air Control Vacuum Reservoir - Replace), or if another procedure is performed, refer to the appropriate Electronic Labor Time Guide for the correct Labor Operation Code and Time.

Important: Loctite(TM) 242 Threadlocker is required to be applied to 24 bolts. Claims received in the amount of retailer cost plus 40% parts allowance will be accepted for the material required to perform the repair. It will be necessary to sell Loctite(TM) 242 to the CSO as "material" using net item code "M". Claims exceeding the amount of $2.48 (cost $1.77 x 1.4 parts allowance) will be returned with return reason 143 - material amount greater than maximum allowed.

Images (Click to make bigger)

Saturday, January 8th, 2011 AT 6:55 PM