You too, are hooked, no doubt!

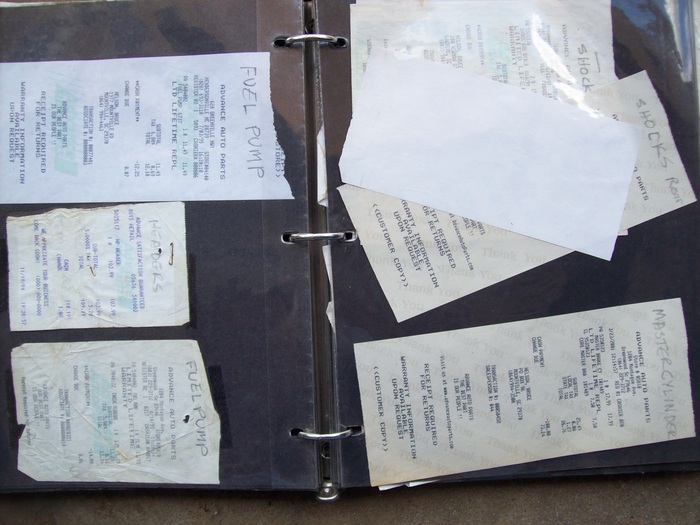

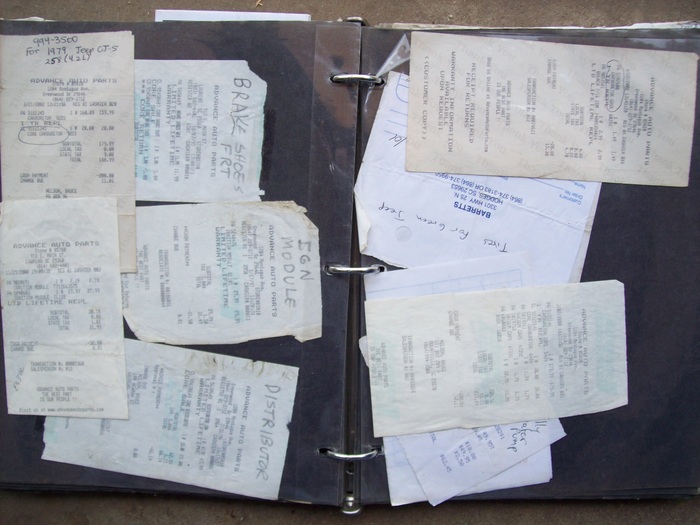

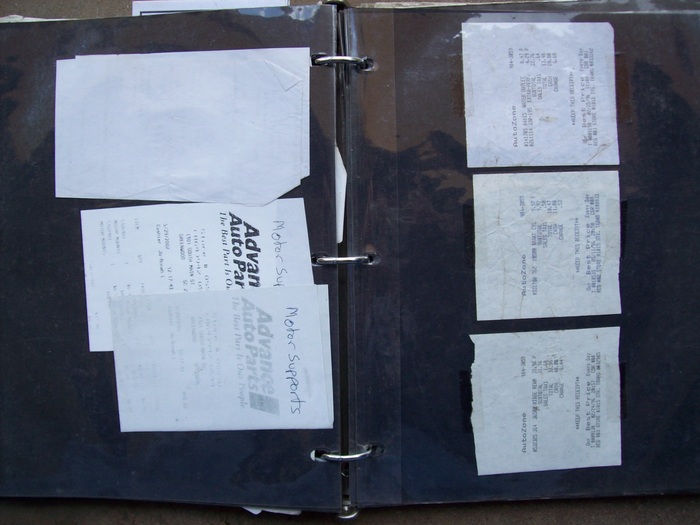

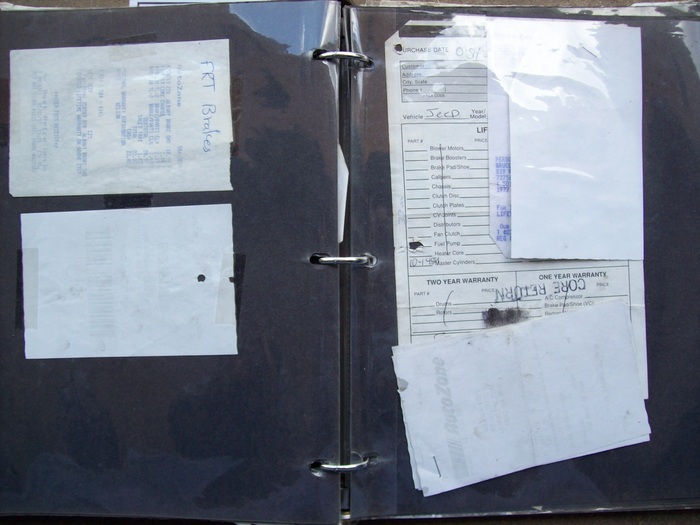

I never made it to the "Tear The Body Off Of My Own, Point" until 1991 When "Willy" became part of the family. Then it was systematically, go thru nearly everything (new bearings and seals, and much, much more!)

It was a 2 year project, I gave $100 for him initially and. Now. Well, we will not even discuss that!

$$$ was the biggest issue, even though labor was Free, I started out in life with Nothing, and I still have most of it left!

I Completely wired him from scratch and to meet my Modified Special Wants and needs (he is far from original, but still has the "Right Look"), I installed a new body (glass, had to run a separate ground to everything. I drove him several years.A quart of oil every 7 miles! The town was glad when I broke down and rebuilt an engine and new clutch assembly. I created SEVERE SMOKE SCREENS everywhere we ventured!

I have no pics from back then, but I do have a VHS Video that I took here and there as I progressed in the beginning. (Now if I can figure out a way to make it digital and snag some pics from it). I am mostly Cyber-Stupid, I ever touched one till I broke my foot and had complications for a year and a half. Now here I am, finally over it--I did it at work, now they say, they do not need me. Their Loss. Someone soon, will have the Best Plumbing Service Technician, This side of the Mississippi!

Did you get my Mostly Modification Albums? (Mega Pics and Explanations)

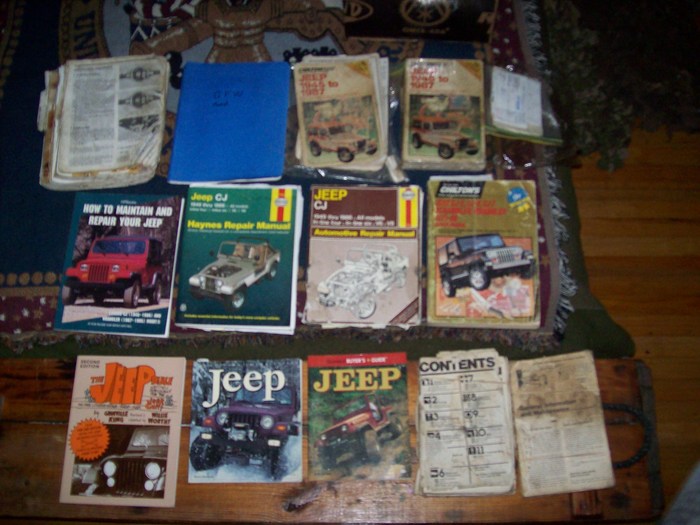

If you have explored the CJ 5 & 7 Forums you have seen other pics of mine. Heres a few.

1) My daughter in "Willy" (1946 Willys CJ2A L-134 Engine), age 3 (my apprentice, her birth-date is my hood number), It's now roadworthy, and lays a Smokescreen. Needs engine

2) Years later, new paint, 1943 "MB" Front grill and soft top

3) Rear

4) Recent--I was sold this 1953 Sears "Allstate" aluminum hard top in '93, unassembled still in the box. Yep, the only top I had for a while (Just went and got it out of the woods at my Parents house, Now my winter top!), I gave $50 for it!---Pup likes being warm too

5) Now at Christmas--Same Daughter in 1st pic, visits from Arkansas (Away from her Evil other parent) This is my Apprentice and my Grandson.

6) When she visited for the Summer(s), she began learning at age 8, was as proficient as I at age 10. This is the way we sometimes save an Electric Cranking for future use (and impress people too!) This is about age 10. She thinks she is "Bad" now that she can drive, but cannot be licensed for 5 more years!

7) Cruisin' Mode

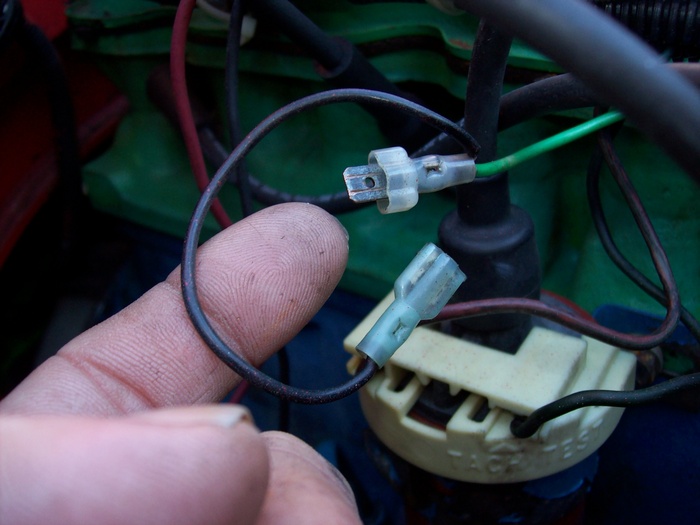

8) Mr. Rebuilt Engine L-4 134 CID---No more smokin'--lots more power--it too modified to "MY SPECS", under the hood to make things User-Friendlier

YOU AND I KNOW THE REAL MEANING OF "JEEP DEDICATION", OTHERS JUST THINK THEY DO, AND HAVE NO REAL CONTEMPLATION OF WHAT HOURS AND HOURS OF "FOCUS" REALLY IS. THEY JUST WANT YOU TO TAKE 'EM FOR A, "LETS TRASH OUT AND DESTROY 'YOUR JEEP', MUDDING EXPERIENCE."----KINDA LIKE THE "CSI GUY" AND HIS BASEMENT SAILBOAT!

YOUR TURN

THE MEDIC

Was this helpful?

Yes

No

Tuesday, February 15th, 2011 AT 3:39 PM