Welcome to 2CarPros.

The code is for the crankshaft position sensor. Is that the sensor you replaced or was it the cam sensor?

Does your scanner have a live data feed? If it does, crank the engine and see if there is an RPM signal. If there isn't, replace the crank sensor.

https://www.2carpros.com/articles/symptoms-of-a-bad-crankshaft-sensor

https://www.2carpros.com/articles/crankshaft-angle-sensor-replacement

Here are the directions specific to your vehicle:

REMOVAL PROCEDURE

IMPORTANT: The crankshaft position (CKP) system variation learn procedure will need to be performed whenever the CKP sensor is removed or replaced.

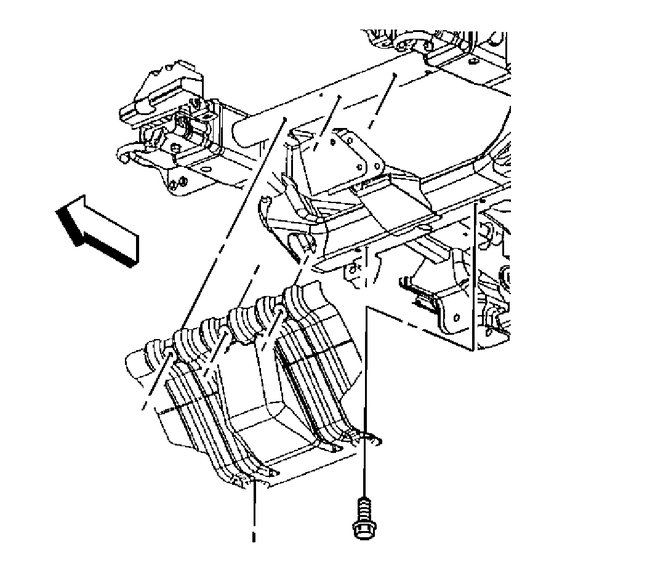

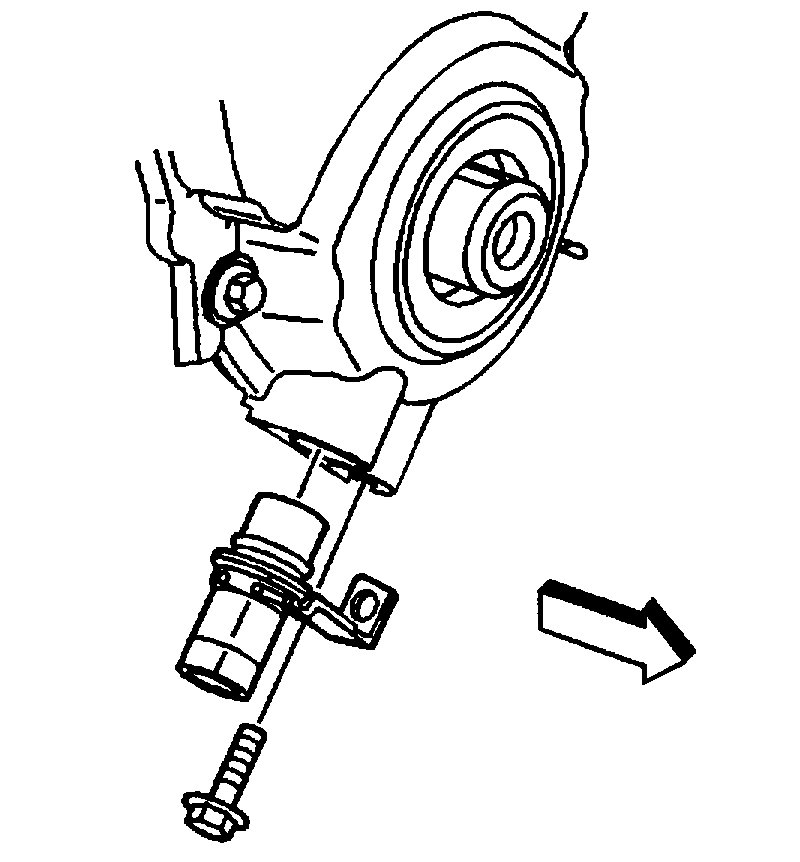

pic 1

1. Raise and suitably support the vehicle. Refer to Vehicle Lifting.

2. If equipped, remove the engine shield bolts.

3. Remove the engine shield.

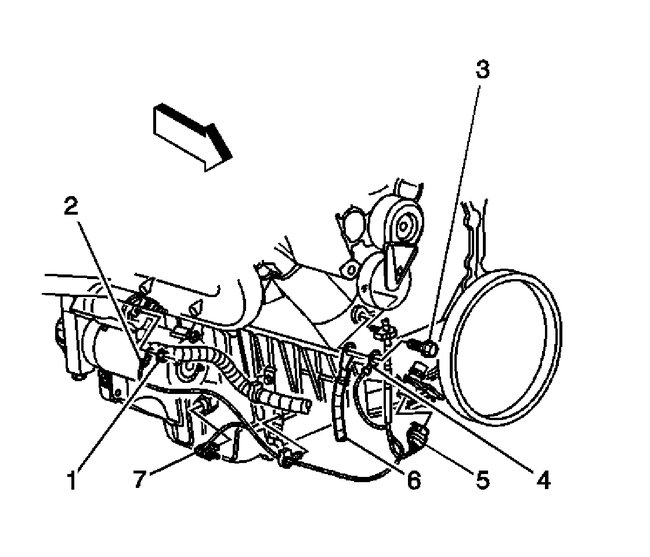

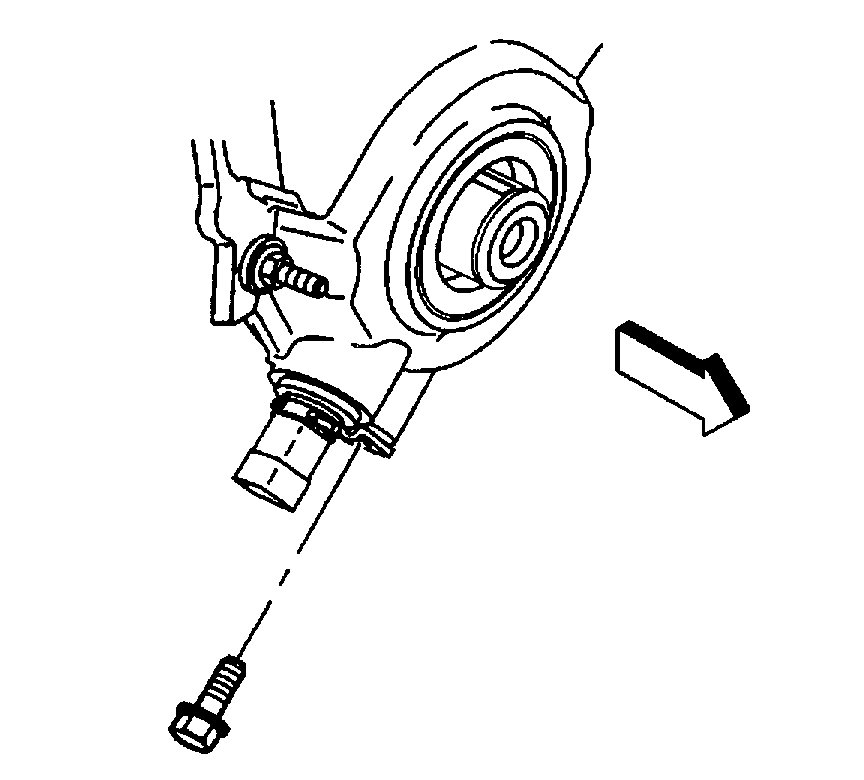

pic 2

4. Disconnect the CKP sensor electrical connector (5).

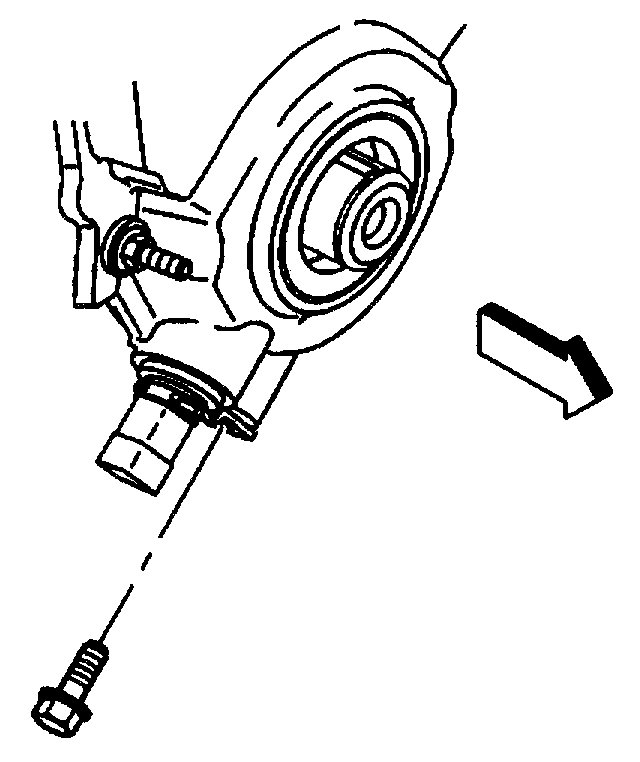

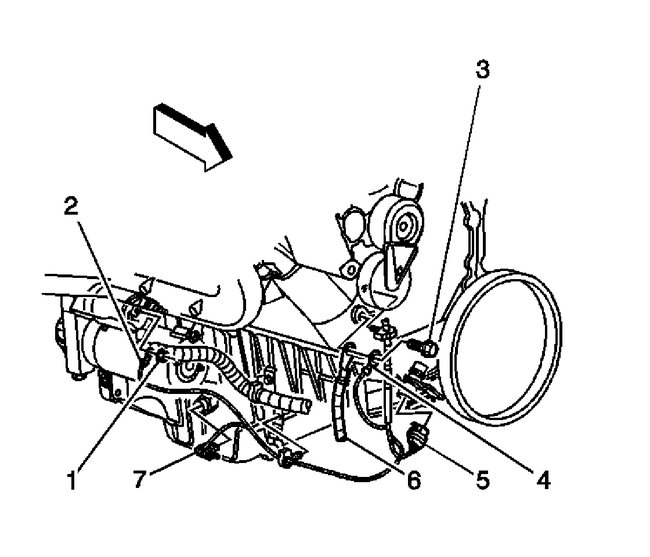

pic 3

5. Remove the CKP sensor bolt.

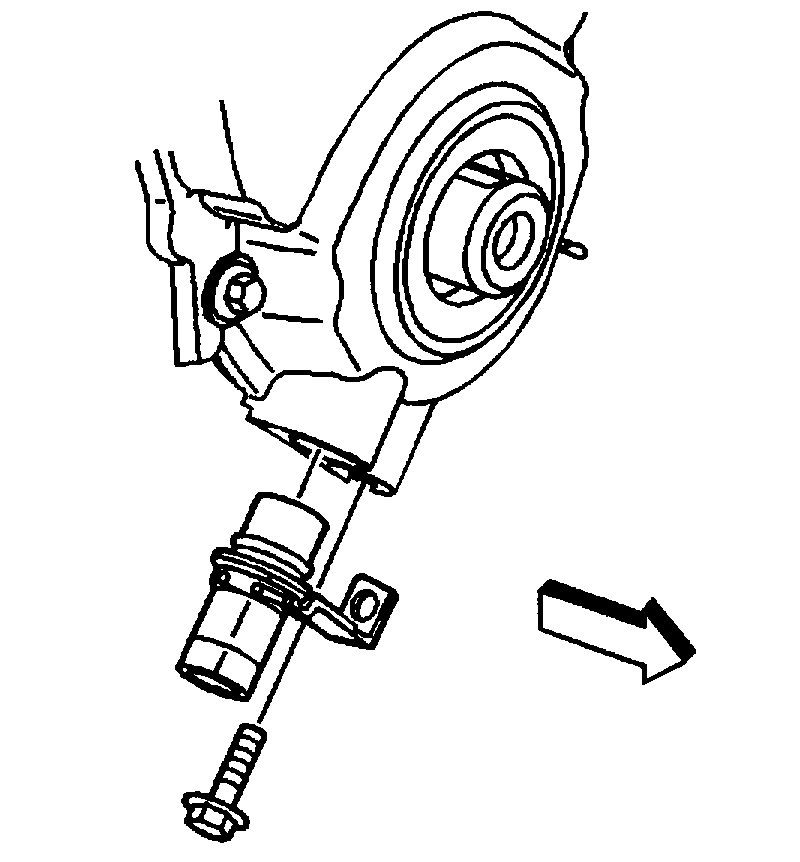

pic 4

6. Remove the CKP sensor.

INSTALLATION PROCEDURE

IMPORTANT: When installing the CKP sensor, make sure the sensor is fully seated before tightening the bolt. A poorly seated CKP sensor may perform erratically and may set false diagnostic trouble codes (DTCs).

pic 5

1. If installing the old CKP sensor, install a NEW O-ring seal.

IMPORTANT: Do not reuse the original O-ring seal.

2. Lubricate the O-ring seal with clean engine oil.

3. Install the CKP sensor.

pic 6

4. Install the CKP sensor bolt.

NOTE: Refer to Fastener Notice in Service Precautions.

Tighten

Tighten the bolt to 9 N.m (80 lb in).

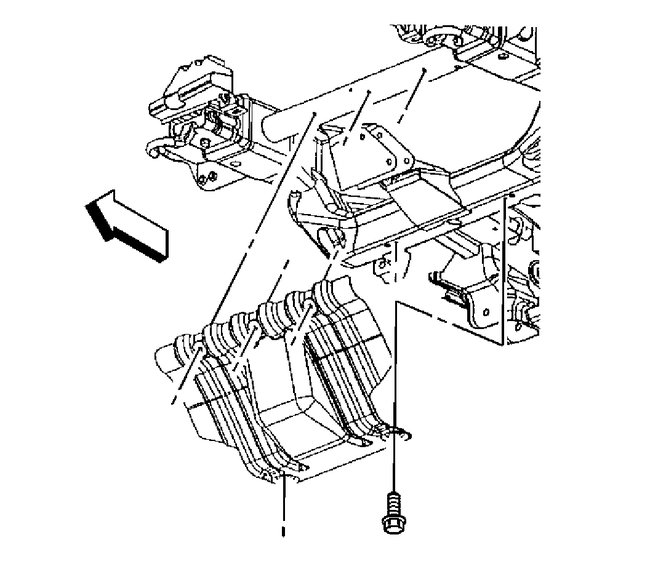

pic 7

5. Connect the CKP sensor electrical connector (5).

pic 8

6. Install the engine shield.

7. Install the engine shield bolts.

Tighten

Tighten the bolts to 20 N.m (15 lb ft).

8. Perform the CKP system variation learn procedure. See: Vehicle > Programming and Relearning

_________________________

Here is the relearn procedure.

Crankshaft Position (CKP) - Variation Learn Procedure

Vehicle Testing and Inspection Programming and Relearning Crankshaft Position (CKP) - Variation Learn Procedure

CRANKSHAFT POSITION (CKP) - VARIATION LEARN PROCEDURE

1. Install a scan tool.

2. Monitor the powertrain control module for DTCs with a scan tool. If other DTCs are set, except DTC P0315, refer to Diagnostic Trouble Code (DTC) List for the applicable DTC that set.

3. Select the crankshaft position variation learn procedure with a scan tool.

4. The scan tool instructs you to perform the following:

- Accelerate to wide open throttle (WOT).

- Release throttle when fuel cut-off occurs.

- Engine should not accelerate beyond calibrated RPM value.

- Release throttle immediately if value is exceeded.

- Block drive wheels.

- Set parking brake.

- DO NOT apply brake pedal.

- Cycle the ignition from OFF to ON.

- Apply and hold the brake pedal.

- Start and idle engine.

- Turn A/C OFF.

- Vehicle must remain in Park or Neutral.

- The scan tool monitors certain component signals to determine if all the conditions are met to continue with the procedure.

The scan tool only displays the condition that inhibits the procedure. The scan tool monitors the following components:

- Crankshaft position (CKP) sensors activity-If there is a CKP sensor condition, refer to the applicable DTC that set.

- Camshaft position (CMP) sensor activity-If there is a CMP sensor condition, refer to the applicable DTC that set.

- Engine coolant temperature (ECT)-If the engine coolant temperature is not warm enough, idle the engine until the engine coolant temperature reaches the correct temperature.

5. Enable the crankshaft position system variation learn procedure with the scan tool.

6. Accelerate to WOT.

IMPORTANT: While the learn procedure is in progress, release the throttle immediately when the engine starts to decelerate. The engine control is returned to the operator and the engine responds to throttle position after the learn procedure is complete.

7. Release when the fuel cut-off occurs.

8. The scan tool displays Learn Status: Learned this ignition. If the scan tool indicates that DTC P0315 ran and passed, the CKP variation learn procedure is complete. If the scan tool indicates DTC P0315 failed or did not run, refer to DTC P0315. If any other DTCs set, refer to Diagnostic Trouble Code (DTC) List for the applicable DTC that set.

9. Turn OFF the ignition for 30 seconds after the learn procedure is completed successfully.

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

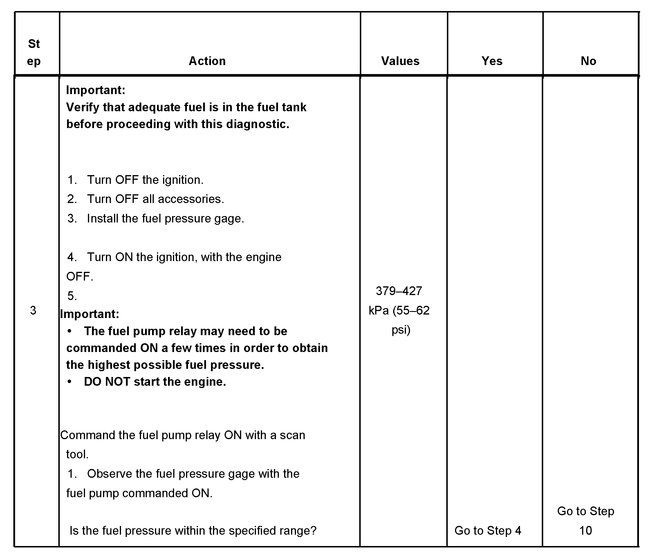

Let me know if this helps or if you have other questions. If you do find it is getting spark, then I recommend checking fuel pump pressure.

https://www.2carpros.com/articles/how-to-check-fuel-system-pressure-and-regulator

See the last pic for specs related to checking fuel pressure.

Take care,

Joe

Images (Click to make bigger)

Monday, August 19th, 2019 AT 8:49 PM