Featured on fuel injected vehicles a throttle body or actuator as they are referred to in new cars is used to control the engine speed via the accelerator pedal. Positioned at the upper portion of the intake manifold when the actuator is closed the engine will run at idle, and when fully open the engine will produce its maximum amount of power. A throttle actuator and throttle body are generally the same part, the throttle actuator is fully computerized (no cable) with no idle air control valve (IAC) and is sometimes referred to as a "drive-by-wire" system which uses an accelerator position sensor (APS) located at the pedal arm to control the actuator. As part of regular engine maintenance the throttle actuator must be serviced, usually at the same time a tune up is performed.

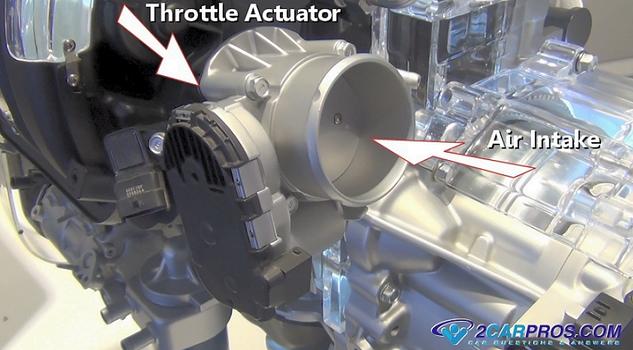

Here is a what a throttle actuator looks like on a 2019 vehicle which shows the

air intake path, you can see the butterfly is closed, normally you cannot see this

part when the air intake tube

is installed.

A throttle actuator is held to the intake manifold using three or four bolts

sealed with a gasket. A computer wiring harness connector is plugged directly into

the throttle actuator motor. A throttle position sensor (TPS) provides the throttle

butterfly position data for the computer.

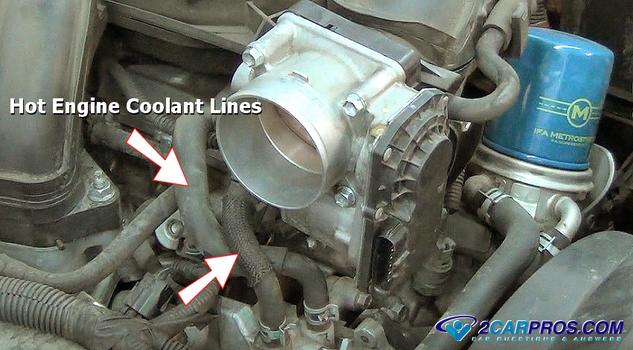

Manufacturers will sometimes run hot engine coolant through the throttle bore

to help heat up the intake air to improve fuel economy.

Older Vehicles

A throttle body is used on vehicles older than 2001-2005 (in general) and have

a throttle cable connected to the gas pedal to open and close the actuator. This

configuration uses an idle speed motor to control engine speed at idle via the computer

program, there are no manual adjustments on a throttle bore, it is completely controlled

by the engine computer. In the image below it shows what an idle air control valve

looks like on a Toyota.

Air bypass ports are designed onto the throttle bore (idle air valve removed)

which facilitate engine idle speed adjustments from the computer.

Questions?

Our certified technicians are ready to answer throttle actuator questions for free. We hope you saved money and learned from this guide. We are creating a full set of car repair guides. Please subscribe to our 2CarPros YouTube channel and check back often for new videos which are uploaded regularly.