Hi,

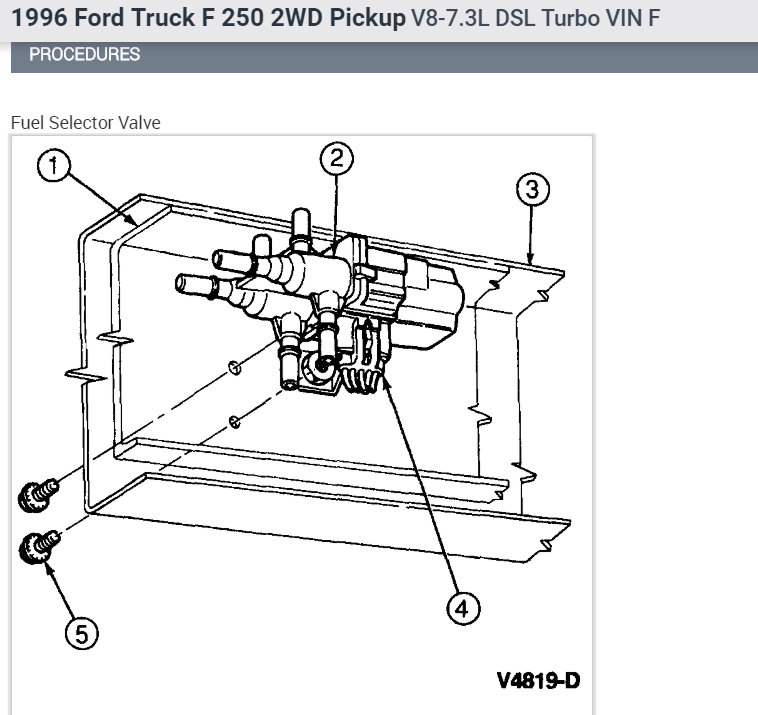

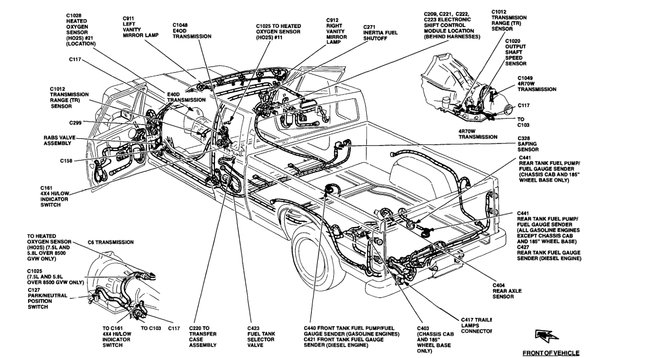

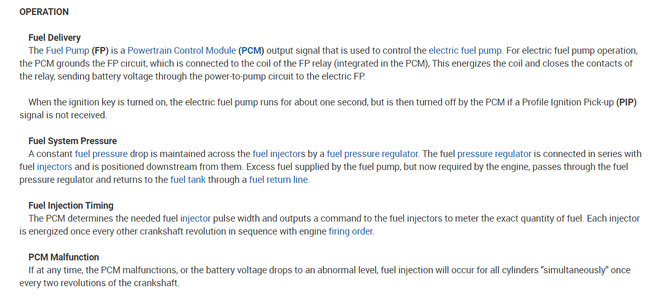

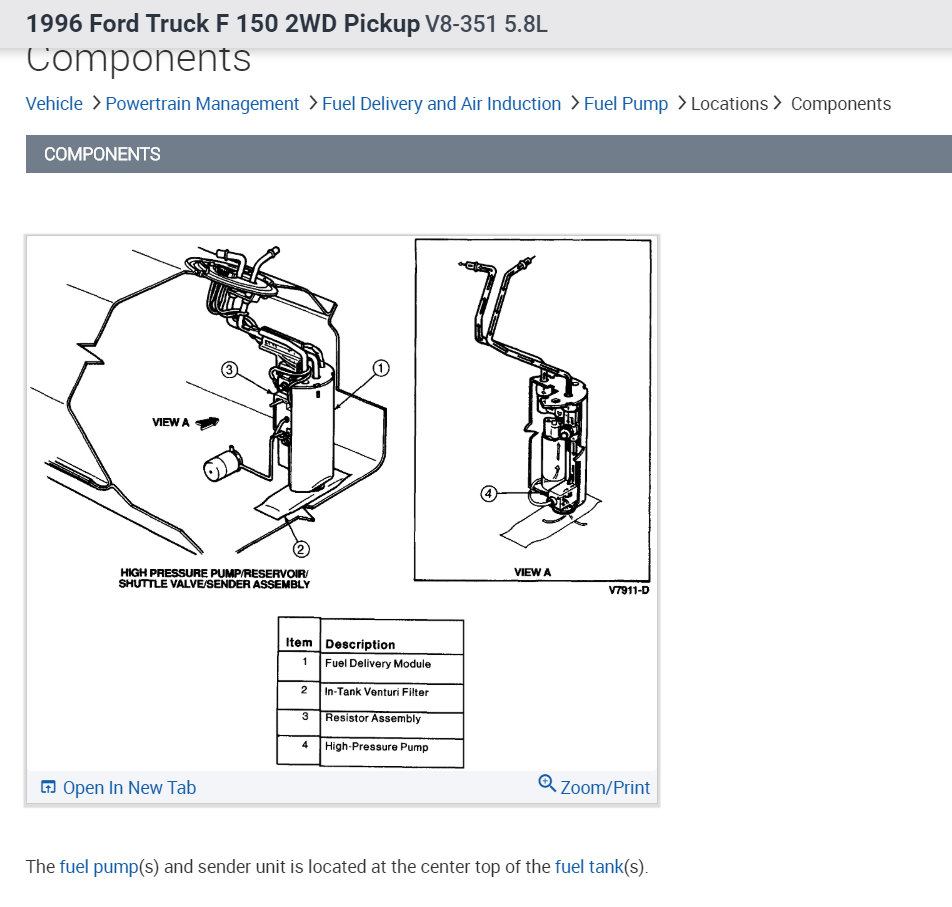

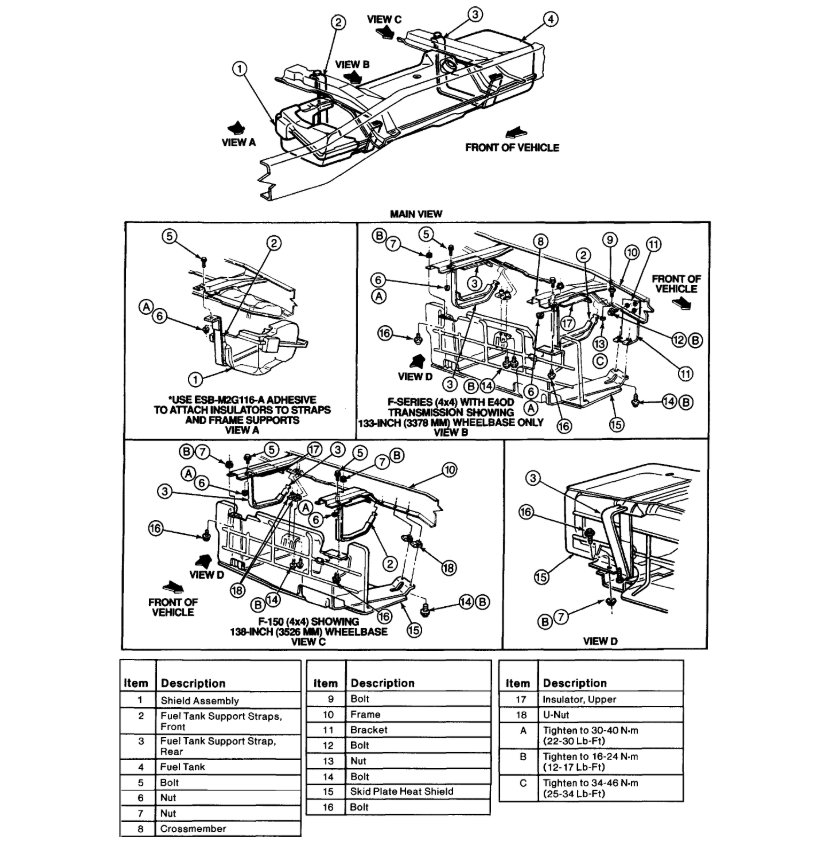

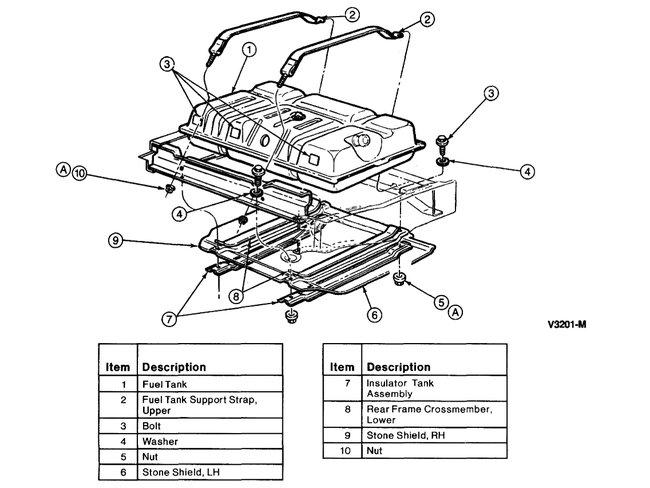

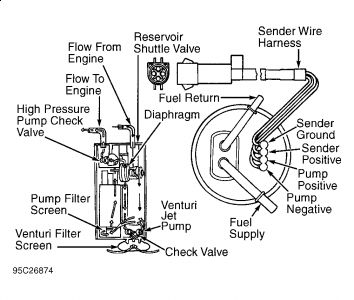

I think I know what is happening. There is a fuel tank reservoir valve under the vehicle that is the likely problem. If you look under the driver's side door on the inside of the frame, there should be a black canister/fuel reservoir. See pic 1.

Check for that first. If it is there, you have two choices. You can purchase them on Amazon or eBay or you can try fixing the one you have.

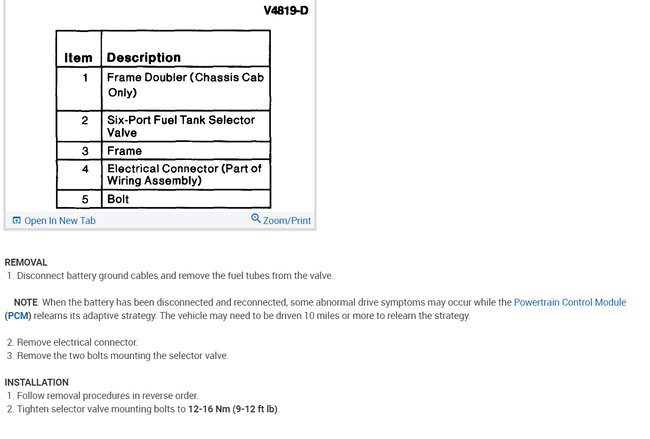

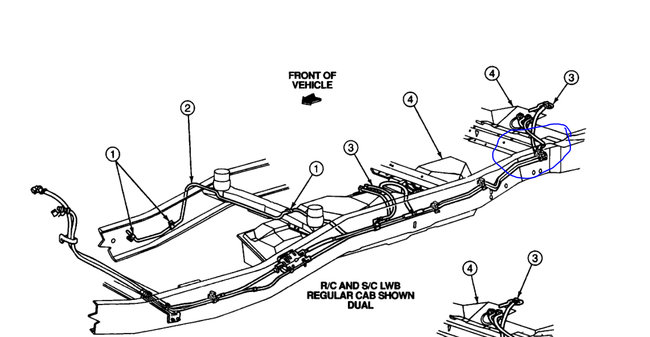

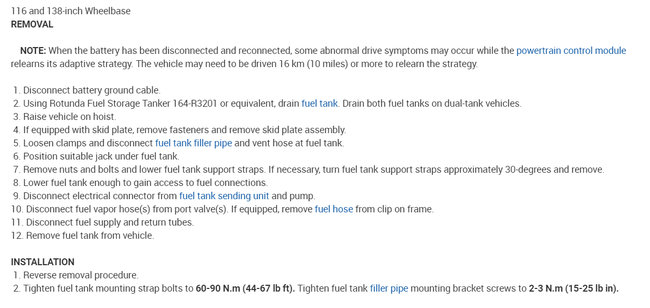

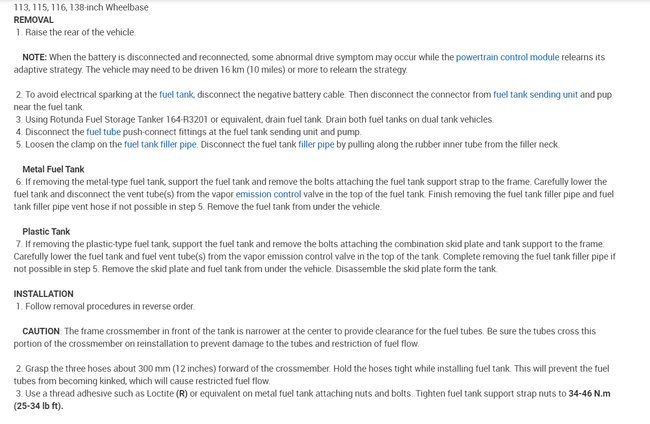

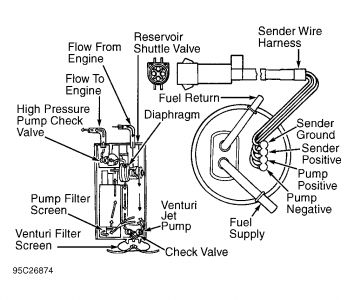

What you will need to do is remove it from the vehicle, and remove the (I think 8) 10mm bolts from the top of it. When removed, there will be an orange diaphragm with one screw holding it in place. Remove the screw to expose a steel round plate. See pic 2.

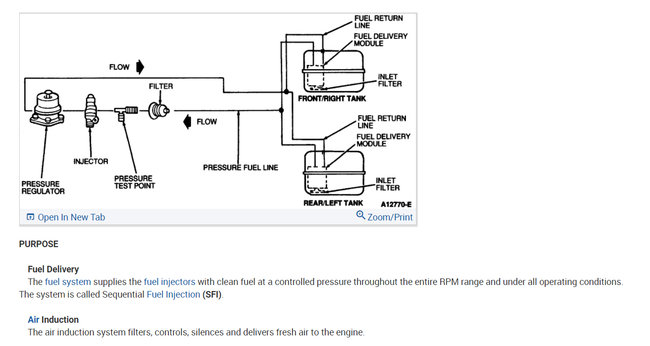

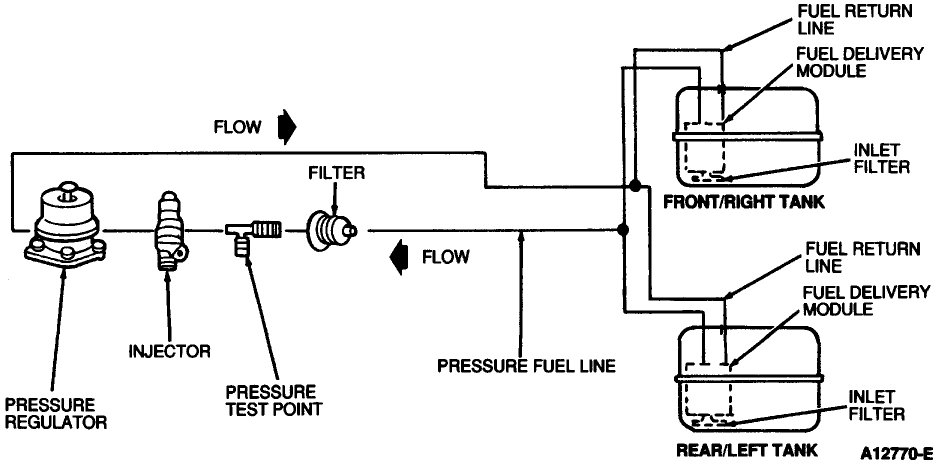

I circled the part I am referring to in the pic. That is the item that determines if the front or rear tank is being used. Now, that steel plate can move up and down. When down, the front tank is being used. When down, the rear is used. What happens is the two steel slide rods attached to the round plate get dirty and no longer freely move up and down. As a result, fuel goes to different tanks when it shouldn't.

Take a good penetrating fluid and spray along the slides that hold the round plate and work it up and down until if feels free and moving smoothly.

Next, put it back together. Because there is fuel pressure in the reservoir, make sure to use a good sealant designed for fuel and heat when you reseal the top.

Let me know if you find it and if this helps. I've done it before because of the cost of replacement parts and it has worked fine. However, I can't guarantee it will do the job in all cases.

Take care,

Joe

Images (Click to make bigger)

SPONSORED LINKS

Saturday, May 29th, 2021 AT 11:18 AM

(Merged)