First put motor mounts back in so everything doesn't fall out

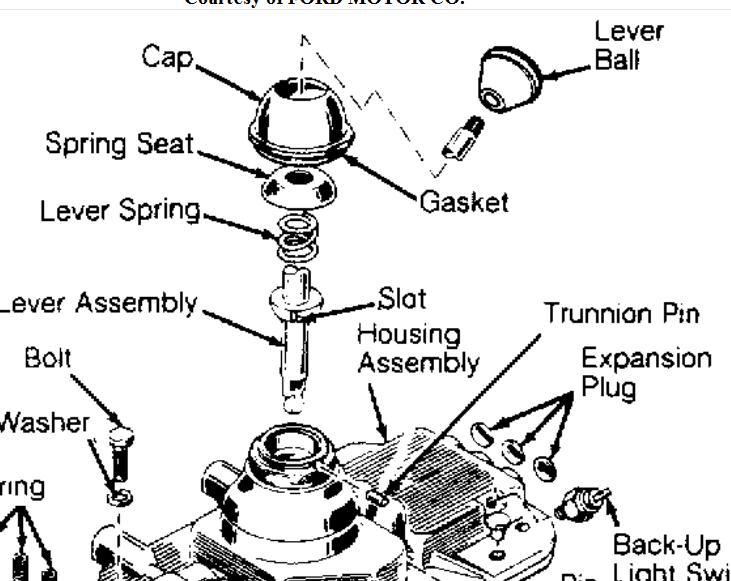

Working from inside vehicle, remove floor mat and body floor pan cover. Remove gearshift lever, shift ball and boot as an assembly. Remove weather pad. Raise and support vehicle. Disconnect speedometer cable.

Disconnect back-up light switch from rear of gear shift housing cover. Disconnect drive shaft from transmission and wire out of way. DO NOT allow shaft to hang free as damage to universal joint may result. Disconnect clutch linkage.

Remove skid plate (if equipped) and heat shield. Support transmission with jack. Remove crossmember gusset-to-frame bolts and gusset-to-crossmember bolts. Remove transmission-to-insulator bolts. Raise transmission and remove insulator-to-crossmember bolts. Remove insulator.

Remove right gusset, crossmember-to-frame bolts and crossmember. Remove transmission-to-clutch housing bolts. Move transmission away from clutch housing until input shaft clears housing. Lower transmission out of vehicle

make sure all 4 bolts are out of trans hooking to flywheel housing.

SPONSORED LINKS

Tuesday, November 5th, 2013 AT 6:21 AM