I AM SO. PROUD. RATHER EXCITED THAT YOU AND grizzly93 TAKE THIS STUFF TO HEART AND STRIVE FOR PERFECTION!

MOST DIYers WANT TO JUST WANNA "GET BY". MAKE IT GO JUST A LITTLE LONGER.

---"WE"--- WANNA PASS 'EM ON DOWN TO THE GREAT-GRAND-YOUNGINS IN SERVICEABLE CONDITION!

ONCE YOU FINISH THIS OPERATION. YOU WILL BE THE MAN. AS YOUR REPUTATION EXPANDS PEOPLE WILL WANT YOU TO DO EVERYTHING FROM A SEAL TO INSTALLING LOCKERS. YOU WILL STILL HAVE TO "LEARN" THE DIFFERENT AXLES YOU WORK ON.

THE LOCAL AUTO SHOPS WITH "MECHANICS", .I MEAN 90% 0R MORE OF THEM DO NOT GO TO THE TROUBLE THAT YOU ARE. "GET BY".30,000 MILES IS WHAT THEY SHOOT FOR. TAKE THE MONEY AND RUN!

MORE SPECIALIZED SHOPS AND THE OTHER 10% WILL DO IT THE RIGHT WAY. THESE ARE JUST MY OPINIONS, I AM PRETTY GOOD AT JUDGING PEOPLE.I MEAN SCRUTINIZING PEOPLE

I WANT YOU TO PLEASE TAKE MANY MANY MANY PICS OF WHAT YOU ARE DOING, EVEN AS YOU ARE INSTALLING SHIMS, LUBING STUFF, PAINTING, ETC.

IT'S BEEN A WHILE SINCE I BROKE INTO ONE AND "I" HAVE NO INNER DIFFERENTIAL PICS.I NEVER THOUGHT ABOUT TAKING ANY BEFORE I STARTED HERE. WITH YOUR PERMISSION I'D LIKE TO COPY AND USE SOME OF YOURS IN FUTURE POSTS TO AID OTHERS OTHERS.

AFTER YOUR DISSEMBLANCE MIX UP OF THE SHIMS, HOW LONG DID IT TAKE YOU TO GET YOUR SIDE SHIMS BACK IN PLACE IN ORDER TO GET YOUR GEAR MESH RIGHT AGAIN?

FUNERAL FOR WIFEY'S GRANDMA IS TOMORROW MORNING, MAYBE I CAN 2CAR MORE SOON AFTER. AND FIX THE RUST ON MR. JEEP THAT I HAVE BEEN PUTTING OFF SO LONG

AT WORK TODAY.I HAD CUSTOMER WHO JUST COULD NOT UNDERSTAND THAT HIS DEFECTIVE "LIFETIME WARRANTY STARTER" COULD NOT BE HONORED

HE SEEMED REALLY SAD AS HE HUNG HIS HEAD. HE WOULDN'T EVEN LOOK UP

I THINK OUR COMPETITOR CHARGED HIM AN "ARM AND A LEG" FOR SOMETHING ELSE. THEY LET HIM KEEP THE "LEG" AS A "DISCOUNT"

I REALLY FELT SORRY FOR HIM WHEN HE SORTA LOST HIS HEAD BEFORE HE AND HIS DRIVER LEFT

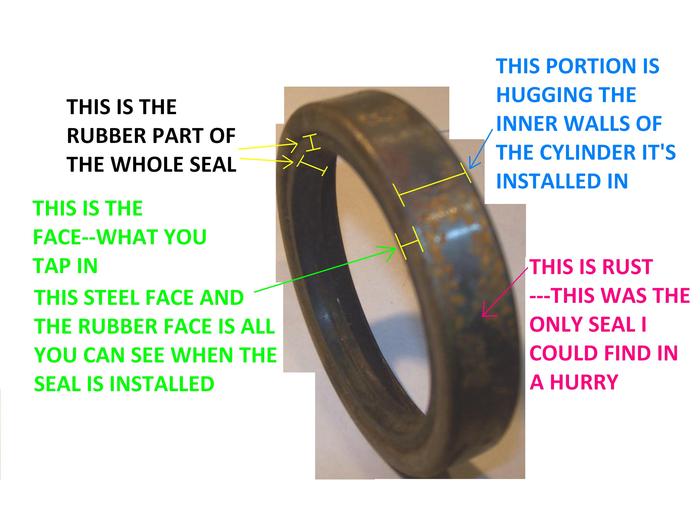

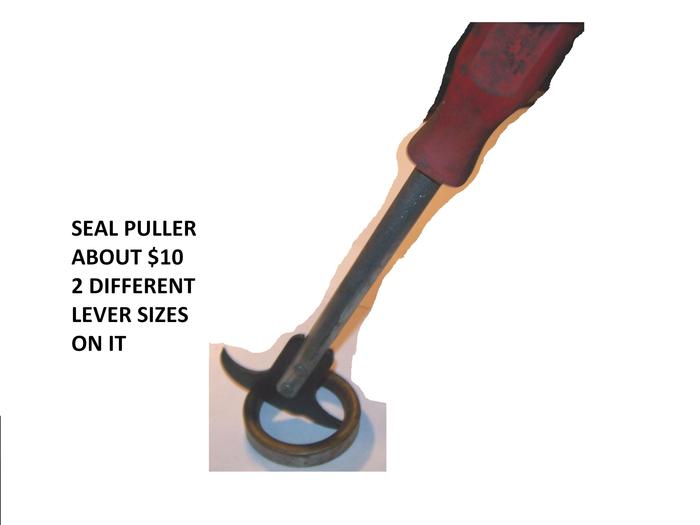

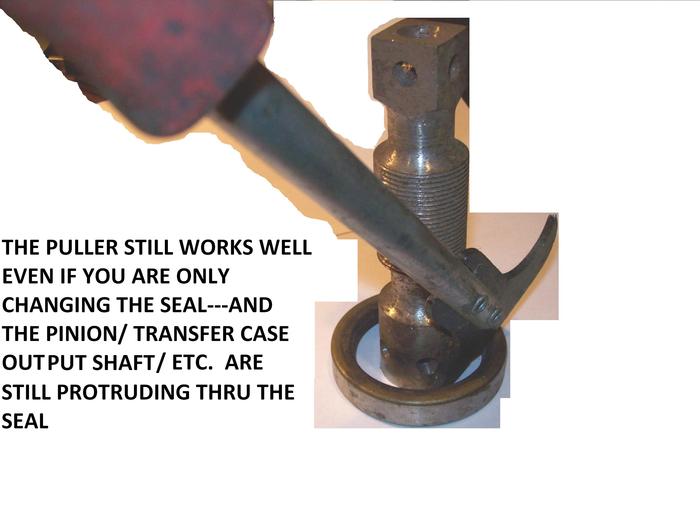

(I REALLY TOOK THESE PICS TODAY AT WORK)

THE MEDIC

Images (Click to make bigger)

Thursday, July 26th, 2012 AT 3:58 AM