ALL RIGHTY THEN

JUST SHOWING YOU---DOES NOT MAKE YOU KNOW THE WHYs (NECESSARY, WHEN I'M NOT AROUND)

DO YOU UNDERSTAND WHAT 4 STROKE MEANS?

ANY QUESTIONS---ASK BEFORE YOU PROCEED!

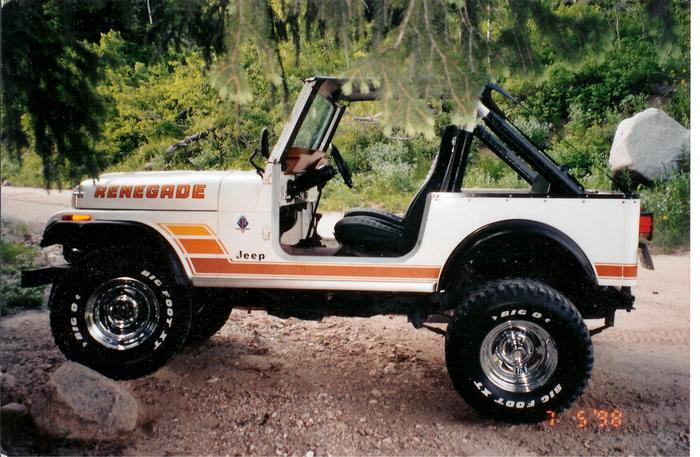

I'M NOT INTO ALL OF THESE "HIGH SPEED MODS", THE BASICS HAVE WORKED FOR ME SINCE I GOT # 1 BACK IN 1981----I DO DO "IMPROVEMENT MODS" OR "USER FRIENDLIER MODS"........NOT MUCH FOR JACKING ONE WAY UP OR RACING ONE

THIS IS HOW A 258 WORKS----OTHER ENGINES ARE SIMILAR!

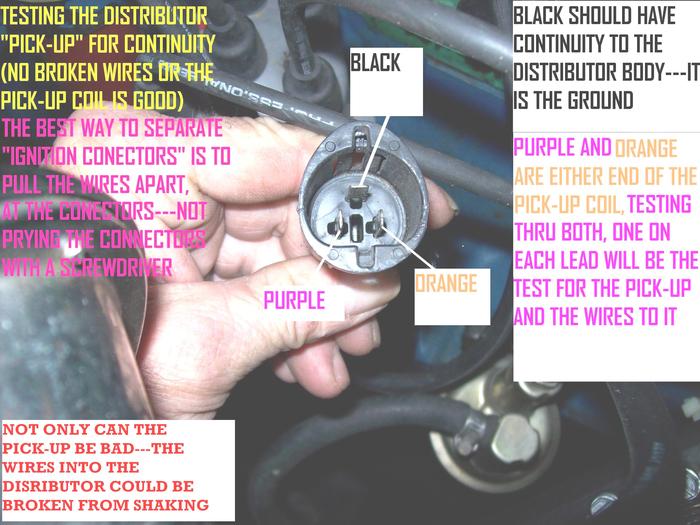

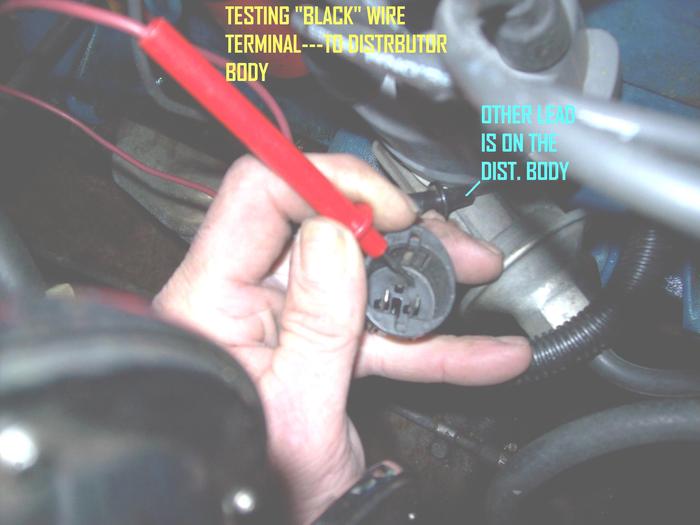

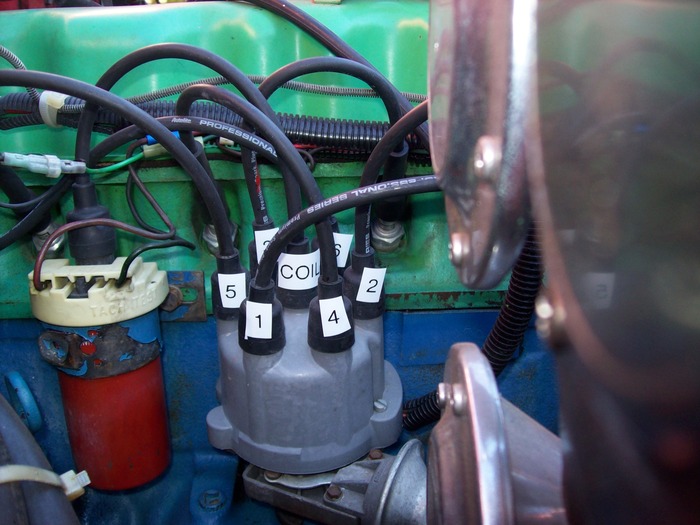

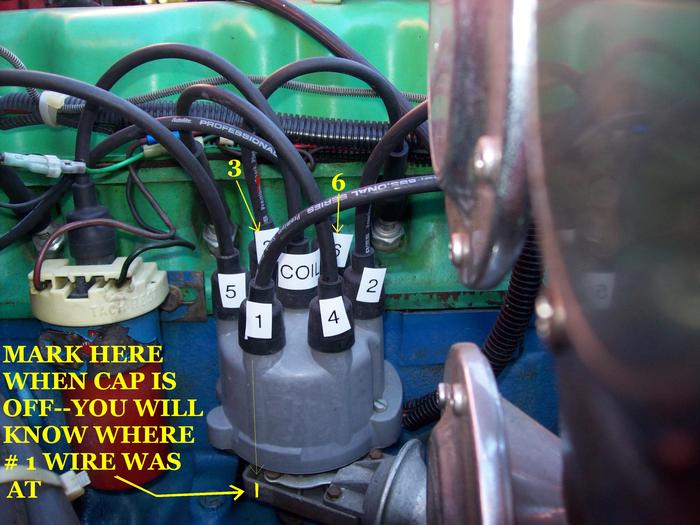

LOOK AT PIC 1VIEWED FROM THE TOP OF THE DISTRIBUTORTHE FIRING ORDER IS 1--5--3--6--2--4 IN A CLOCKWISE DIRECTION

PIC 1 IS MY JEEP----MY WIRES ARE ON EXACTLY AS THE BOOK SHOWS

HERE'S THE THING---IT WILL STILL WORK---IF I PUT NUMBER 1 WIRE ANYWHERETHEN START THE CLOCKWISE SEQUENCE FROM THAT POINTTHE THING THAT MOST DO NOT UNDERSTAND IS THE ENGINE MUST BE ON TOP DEAD CENTER---THEN WHEN YOU INSTALL THE DISTRIBUTOR THE ROTOR BUTTON MUST POINT AT #1 WIRE/ TOWER.....WHEREVER #1 IS!!!!.....THE ENGINE DON'T CARE AS LONG AS EVERYTHING IS LINED UP INTERNALLY!

JUST TO KEEP THINGS ORDERLY---WE WILL INSTALL YOURS BY THE BOOK TOO---THEN IN THE FUTURE---THE BOOK WILL MAKE MORE SENSE---SHOULD YOU FORGET THIS STUFF

SO LOOK AT #1 WIRE ON MINE, IT'S JUST ABOVE THE END OF THE VACUUM ADVANCE ARM THAT YOU CAN SEE AT THE BOTTOM OF THE DISTRIBUTOR----1-5-3-6-2-4 CLOCKWISE----INSURE THEY CORRESPOND WITH THE SPARK PLUGS...."1" IS AT THE FRONT OF THE ENGINE---"6" IS AT THE BACK!

NOW THEN---TAKE A MARKER AND MARK THE DISTRIBUTOR BODY BELOW THE PLASTIC DISTRIBUTOR CAP---WITH A VERTICAL LINE---SEE PIC 2

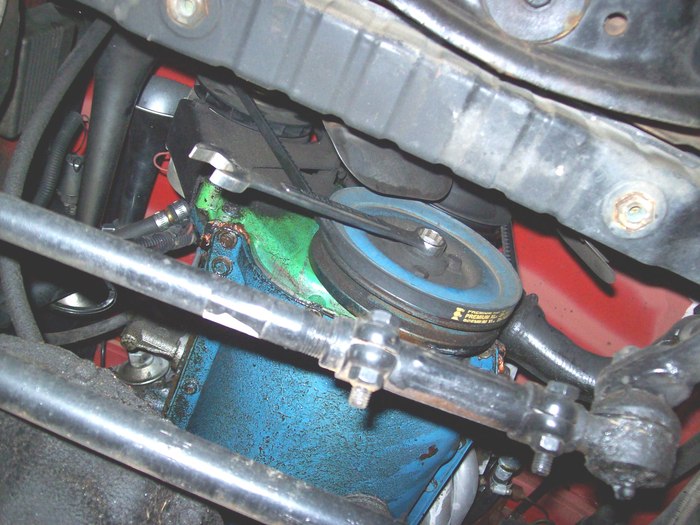

THE NEXT THING I WILL SHOW YOU IS I LIKE TO EXPLAIN TURNING THE ENGINE OVER WITH A RATCHET OR WRENCH---SEE PIC 3

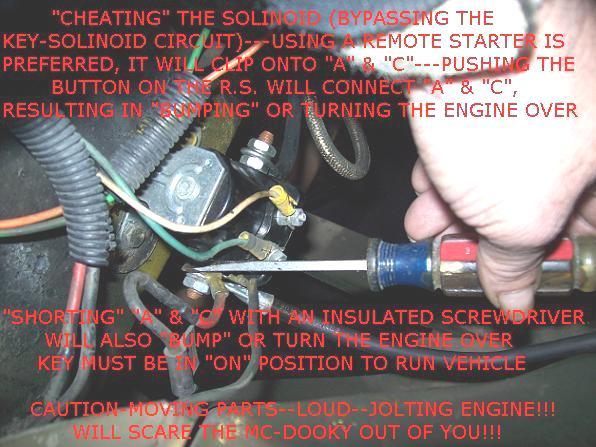

IF YOU BUMP IT WITH THE KEY OR WITH A "REMOTE STARTER"---YOU RUN THE RISK OF OVERSHOOTING TDC (AND NOT KNOW IT)

THE RATCHET/ WRENCH WILL DO JUST FINE FOR GETTING A "COMPRESSION SPIT"

YOU WILL REMOVE #1 SPARK PLUG ---SO YOU CAN STICK YOUR THUMB IN THE HOLE----OR YOU CAN LEAVE THE PLUG IN WITH MAYBE JUST 2 OR 3 THREADS HOLDING IT IN

THE IDEA HERE IS TO ROTATE THE ENGINE CLOCKWISE ---MAYBE UP TO 2 REVOLUTIONS ---REMEMBER THIS IS A 4 STROKE---IT WILL ONLY BUILD COMPRESSION ONE TIME IN 2 REVOLUTIONS

WHEN IT DOES---BUILD COMPRESSION---YOU WILL HEAR A "SPIT" AT YOUR THUMB---OR A "HISS" AT THE VERY LOOSE #1 SPARK PLUG

STOP----STOP ---STOP!!!!

WE ARE STARTING COMPRESSION!.........(NORMALLY COMPRESSING THE AIR/ FUEL MIXTURE IF IT WERE RUNNING)

WE WANT TO FINALLY STOP AT THE "END OF THE COMPRESSION STROKE"

WHEN THE ENGINE "IS" RUNNING---THIS IS THE EDGE OF THE CLIFF!

THE PISTON WILL START "DOWN" AND THE SPARK PLUG WOULD THEN FIRE.......(FIRES ON THE "POWER STROKE")......THIS IS THE REASON WE MUST POINT THE ROTOR BUTTON AT #1.......WE ARE DEALING WITH THE #1s VALVE TIMING......#1 IS THE ONE THAT SHOULD BE FIRING NOW!!!!

WE ARE ALMOST THERE!

FORGET THE HISS AND SPIT....IT HAS GOTTEN YOU CLOSE TO WHERE YOU NEED TO BE!

WE WILL NOW VERY SLOWLY CONTINUE TO TURN THE ENGINE CLOCKWISE WHILE WATCHING THE TIMING MARKS!

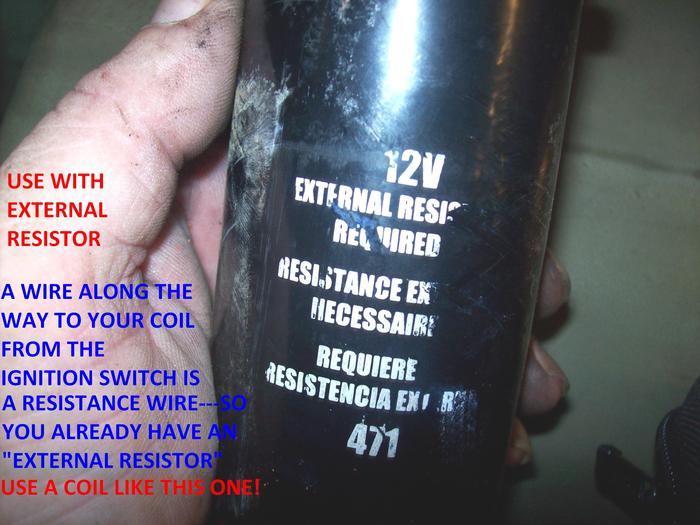

WE WANT TO STOP ON "0" (ZERO) SEE PIC 4

THE MARKS SHOULD COME UP IN LESS THAN A 1/2 REVOLUTION OF THE CRANK (PROBABLY MORE LIKE A 1/4 TURN)IF YOU WENT ANY FURTHER THAN 1/2 A TURN..........

DO IT AGAIN FROM THE BEGINNING.....YOU WENT TOO FAR!!!

----ON A 258 "ZERO" IS THE 2ND MARK UP FROM THE BOTTOM---ZERO IS TOP DEAD CENTER OR "TDC"

TDC IS OUT TIMING ALIGNMENT "KNOW POINT"EVERYTHING IS IN SYNC WITH THIS--LIKE THE CAM AND DISTRIBUTOR

YOU MIGHT USE SOME CARB CLEANER AND CLEAN YOUR TIMING MARKS----WHITE OUT IN THE HARMONIC BALANCER MARK WILL MAKE IT STAND OUT

OK

WONDERFUL!!!

WE ARE ON TDC!!!!!

REMOVE THE DISTRIBUTOR CAP AND SEE WHERE THE ROTOR BUTTON IS POINTING

IF IT'S DEAD ON AT YOUR MARK (OR VERY CLOSE) THAT YOU DREW ON THE BODY.........NORMAL TIMING WITH A TIMING LIGHT WILL MAKE IT RIGHT

IF IT'S POINTING ELSEWHERE----TAKE THE HOLD DOWN FORK OFF LIFT THE DISTRIBUTOR OUT SLIGHTLY (SHOULD BE A ROUND GASKET UNDER IT)

IT WILL TWIST THE ROTOR SHAFT, ON THE WAY UP

ROTATE THE ROTOR BUTTON SO THAT AS IT SLIDES BACK IN---WHEN IT SITS ALL OF THE WAY DOWN THE ROTOR BUTTON IS POINTING AT YOUR MARK

ALMOST DONE!!!!

IT MAY NOT SIT BACK DOWN ALL OF THE WAY?????....WHY????

DON'T FORCE IT!!!

THE BOTTOM END OF YOUR DISTRIBUTOR SHAFT IS A "FAT STRAIGHT SCREWDRIVER POINT"

OF YOU LOOK DOWN IN THE DISTRIBUTOR HOLE WITH A FLASHLIGHT YOU WILL SEE A SLOT LIKE A STRAIGHT SCREW HEAD IN THE BOTTOM..........THIS IS THE OIL PUMP !!!

AS THE CAM TURNS THE DISTRIBUTOR---THE DISTRIBUTOR TURN THE OIL PUMP!

THIS IS SIMPLE ---IT MAY TAKE A FEW TRIES

WE NEED TO LINE UP THE OIL PIMP SHAFT WITH A LONG SCREWDRIVER---SO THAT THE DISTRIBUTOR WILL DROP IN FULLY......I USUALLY GIVE IT AN 1/8TH OF A TURN AND TRY TO DROP IT IN--ANOTHER 1/8TH AND TRY---ANOTHER 1/8TH......

IN THE END

YOU HAVE NOT MOVED THE ENGINE (CRANK) FROM TDC---THE DISTRIBUTOR BODY----HAS AMPLE CW AND CCW ABILITY WITHOUT BOTTOMING AGAINST THE BLOCK (SO WE CAN TIME IT)---THE ROTOR BUTTON IS POINTING AT THE MARK ON THE DISTRIBUTOR---THE DISTRIBUTOR IS ALL THE WAY DOWN IN IT'S HOLE

PUT THE HOLD DOWN FORK ONINSTALL THE DISTRIBUTOR CAP

REMEMBER---I DON'T LIKE TO BUMP WITH THE STARTER---YOU WIND UP OVERSHOOTING THE MARKS---YOU DO THE REST OF THE PROCEDURE........YOU ARE NOW 180 DEGREES OFF.....BUT YOU THINK YOU ARE ON????

I'M SENDING "DAVID AND CHAD" TO GIVE YOU A HAND.....LET THEM EXPLAIN THIS A FEW TIMES BEFORE YOU START.....THEY DON'T MIND AT ALL!

CLASS 1

http://www.youtube.com/watch?v=5a2X9mSSlQY

CLASS 2

http://www.youtube.com/watch?NR=1&v=FHX1yXVyIMg&feature=endscreen

OK---LATE AND I'M TIRED......I THINK I HAVE TOLD YOU CORRECTLY

ASK IF THERE'S AN ISSUE

SEND PICS OF YOUR ENGINE---GETTING STUFF CORRECT---THEN CORRECT TIMING---THEN CARB TUNING ARE GONNA BE NEXT!

YOUR TURN

THE MEDIC

Images (Click to make bigger)

Sunday, February 3rd, 2013 AT 8:29 AM