Monday, July 24th, 2023 AT 8:36 AM

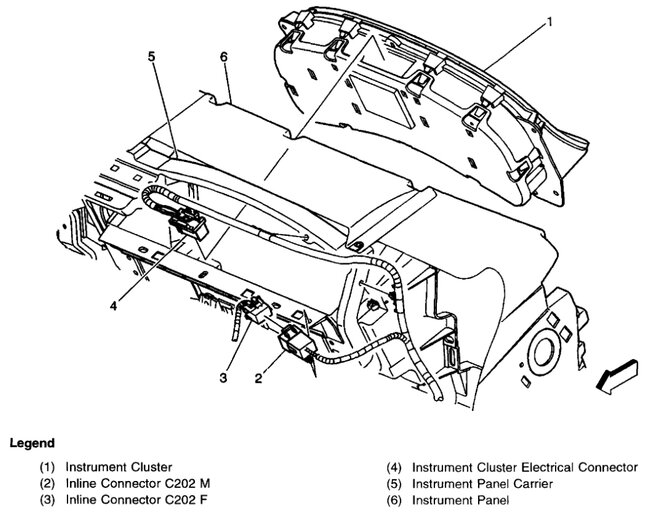

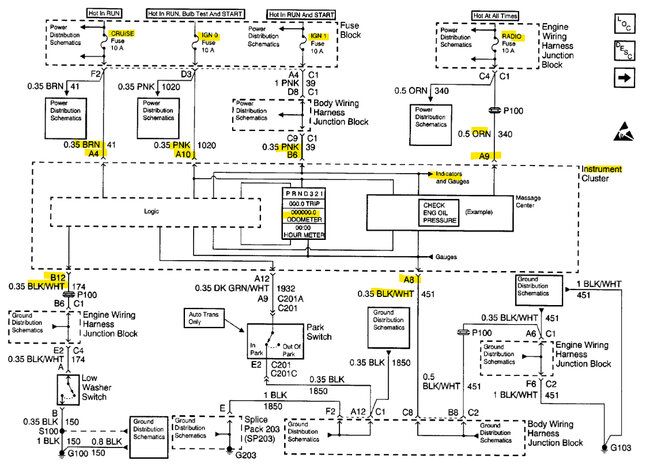

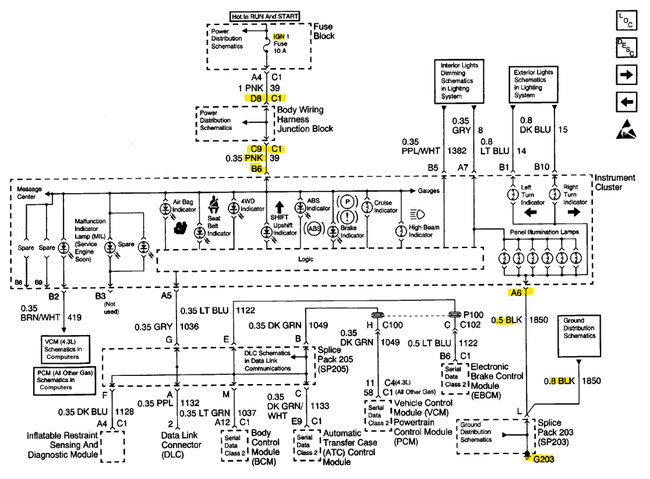

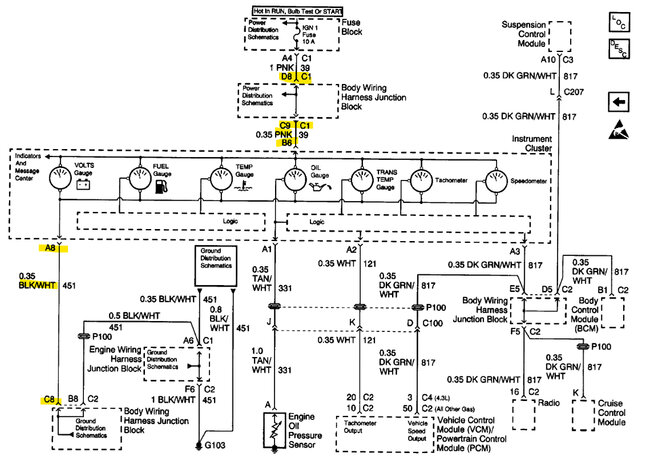

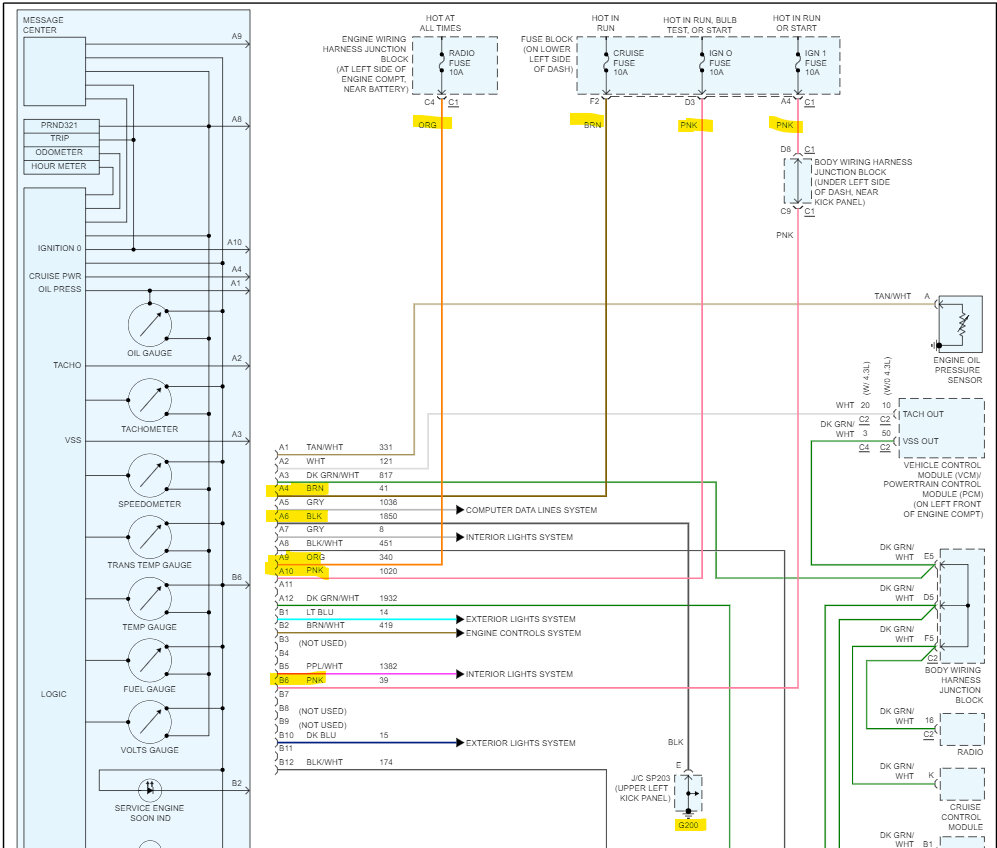

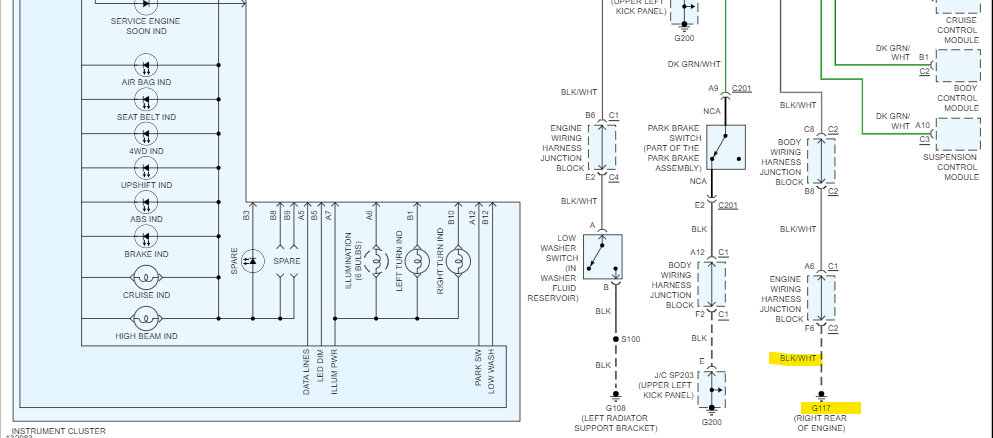

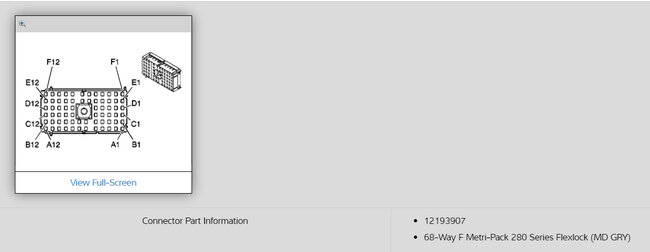

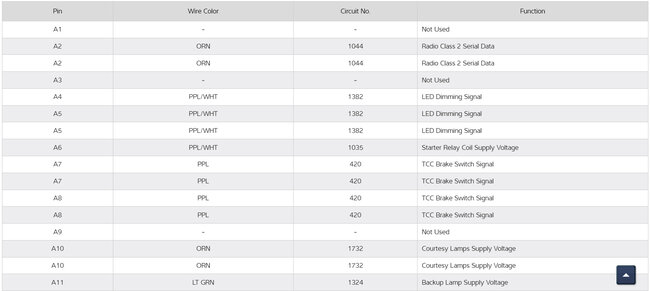

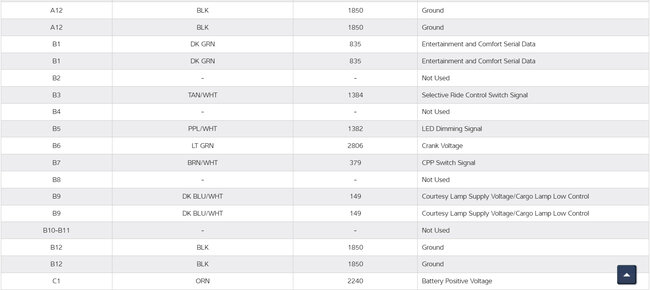

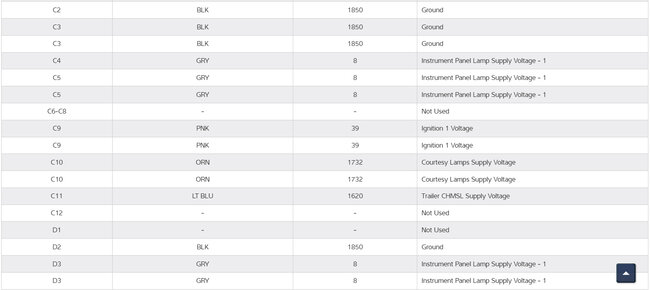

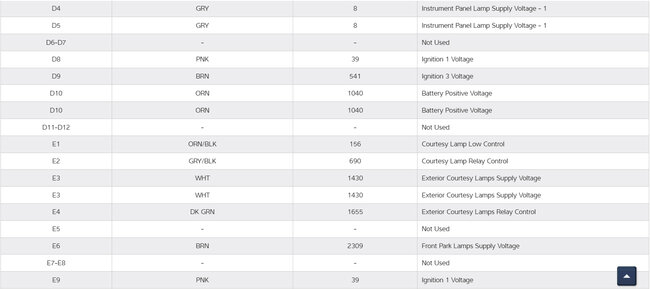

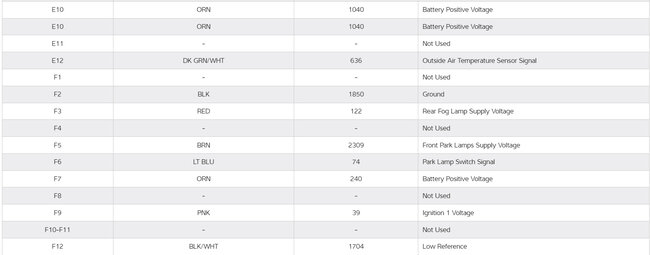

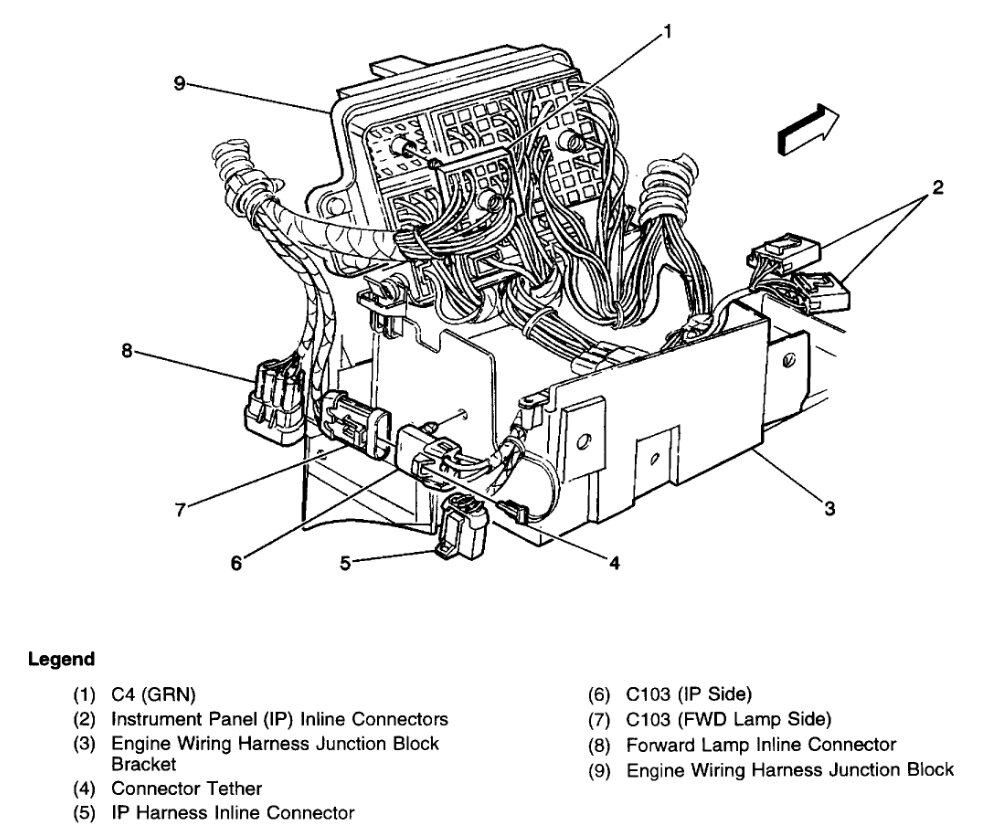

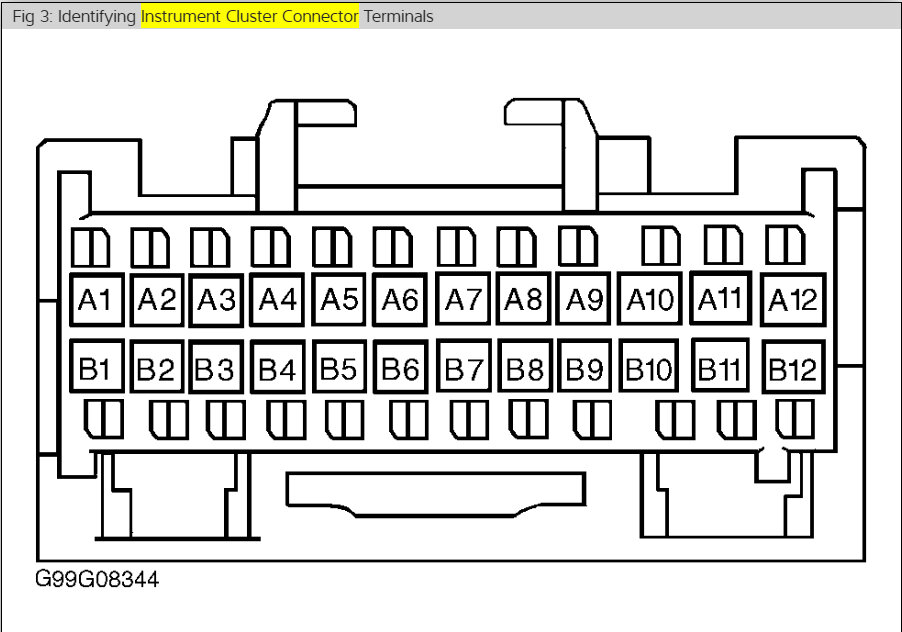

Instrument panel gauges and odometer are intermittent. On and off when hitting a bump. Checked for cold solder joints on the panel. After reconnecting the cluster and turning power on to test I noticed that as I moved it around it would go on and off. I suspect broken wire/s in the harness. I need the harness diagram for my vehicle VIN W to troubleshoot. Any help would be greatly appreciated.