The first issue is the need for using a click-type torque wrench. It sounds like you have that covered. Most do-it-yourselfers, and even some experienced mechanics aren't aware of the importance. That includes a friend of mine with a body shop where he specializes in rebuilding one and two-year-old smashed Dodge trucks. He lost a pair of his rear duallies when I was on a short trip with him, and he still refuses to use his over-priced Snapon torque wrench. The only wheels that ever get torqued in his shop are those in there when I'm killing time helping him.

Ford's torque specs for your wheels have a rather broad range of 83 to 112 foot pounds. I wouldn't go much higher than 100 - 105 foot pounds with cast wheels. 110 foot pounds should be good for steel wheels.

Let me interject a side note here, especially for the benefit of others who might be researching this topic. It's fairly common to find damaged studs and lug nuts when removing a wheel, either for rotation, replacement, or when doing a brake system inspection. Sometimes we have to cut the nut off because it is just spinning, and that often results in damage to the wheel. Naturally, you, as the person working on the vehicle, gets the blame from the owner for causing that damage, but it's important to understand that damage was done by the previous person who installed that wheel, when they over-tightened the lug nuts. Very often that is the owner himself. You have to explain to the owner that lug nuts do not become damaged by removing them. They develop peeled threads from over-tightening, and that was done at the last service.

As for the size of the studs, that is not an issue of the wheel's weight. That's a factor related to the weight of the truck. Cast wheels are used to reduce weight for better fuel mileage, but the studs are designed to be used with steel or cast wheels.

The first consideration is when installing cast wheels, and after replacing the studs, the torque should checked again after about 50 - 100 miles. New studs might not have pulled all the way in yet. Cast wheels are relatively soft, and any deformity in the friction area or small chips of dirt or debris will rub away leaving the nut insufficiently tightened.

Next, if you have aftermarket wheels, most of them are designed to fit many models with the same bolt spacing. To achieve that, the center hole has to be large enough so the wheel will fit on all those models. Fords especially use original wheels that fit very tightly on the hub, often to the point a 20-pound mall is needed to remove the wheel. Lug nuts and studs are not designed to hold up the weight of the vehicle. That is the job of that center hole in the wheel. When the hole is larger than the hub, it falls on the studs to do that. The constant up and down forces on the wheel are going to work the nuts loose. The nuts are only supposed to hold the wheel to the hub. They're not meant to hold up the vehicle's weight.

The rest of the issues have to do with the studs and wheel themselves. Once a wheel has fallen off, regardless of the cause, it is almost a certainty the curved friction surface where the nut contacts the wheel will be chewed up or deformed. The shape of those surfaces are critical that they match. It's that tiny patch where the friction is all that holds the nuts tight. Once a wheel or lug nut has been deformed, they have to be replaced as they will never remain tight with that damage.

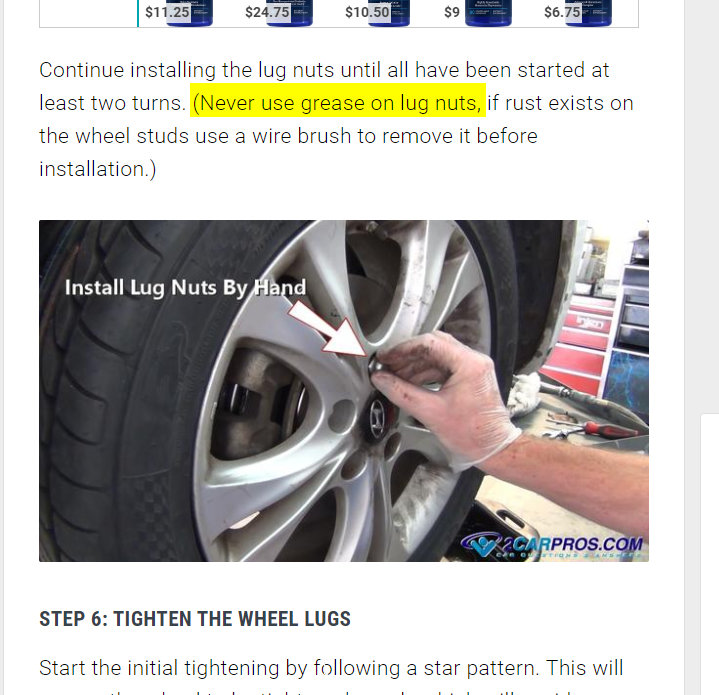

Related to that is the use of grease on the studs. First, most import vehicles use "anodized" studs. Those have a light yellow, light green, light blue, or silver color. That anodized coating is a lubricant in itself and no grease of any kind is supposed to be used on them. Some greases will melt that coating resulting in the threads peeling when you try to remove the nuts, even when they were tightened properly the last time. When you do use grease on non-anodized studs, use just a very light coating to prevent rust. Many people think if some is good, more must be better, but that is not the case. The problem develops when you use an air impact wrench to run the nuts on, even though you stop short, then finish the job with the torque wrench. That wad of grease builds up ahead of the nut, then centrifugal force flings it out onto the wheel. There it gets caught on the friction surface and prevents the nut from holding on. If you do use a little grease, run the nuts on by hand, then torque them.

Also be aware to never ever use any type of anti-seize compound on the studs. That is serious enough that you might get one verbal warning, but at most shops you'll be fired instantly. I did allow my students to use that around the center hole since we're in a state where they throw a pound of salt on an ounce of snow, and rust is common, but never on the studs. Since you're a mechanic, you might appreciate my story from when I was the suspension and alignment specialist at a very nice family-owned Chrysler dealership. Since I was back-logged with other jobs, a coworker installed a pair of front struts on a Dodge Dynasty, and being the conscientious fellow he was, he coated everything with anti-seize compound to prevent a rust problem that never actually occurred. Unlike other Chrysler models that used "cam bolts" to make alignment adjustments easier, these just relied on the clamping forces of two really fat bolts to hold the wheel in alignment. They hold the wheel so well, hitting pot holes at high speed rarely causes them to slip. In this case, when he sent the car to me for the alignment, both front wheels had tipped in on top as far as they could go. I jacked it up, pulled the wheels out, tightened the bolts, let the car down on the tires, and the wheels immediately slipped again. That was frustrating enough but then the same thing happened a second time. The third time they slipped, I was frustrated with myself, thinking I wasn't tightening those bolts enough, I really cranked them down, so much so, that I snapped one of them apart right in the middle. I'm a little guy, but I pulled a bolt apart that was 3/4" in diameter, with a 1/2" ratchet. Once I took the wheel off to see what was going on, I found the anti-seize compound slobbered all over. That all had to be washed off for the alignment to hold. Even using axle grease doesn't result in that problem, so it shows how serious it would be to use it on wheel studs. No shop owner wants to risk the liability or lawsuits. That's why the offender usually gets invited to look for a job somewhere else.

Here's a link to a related article:

https://www.2carpros.com/articles/wheel-removal-and-re-installation

You probably have had this training already, but it's good reading for anyone else doing this job at home.

Wednesday, April 1st, 2020 AT 5:06 PM