Hi guys. If I could stick my nose in here for a moment, testing speed sensor is pointless. They do not measure a resistance like a throttle position sensor or temperature sensor. Two-wire speed sensors, including wheel speed sensors for anti-lock brakes generate an AC signal voltage with the frequency proportional to speed. As with all voltages generated this way, speed is an important part of the strength, or voltage of the signal, but that voltage doesn't matter, as long as it's high enough that the computer can read it. Then, it's the frequency it cares about, not the voltage.

Three-wire speed sensors generate the AC signal voltage the same way, but then there's additional circuitry that puts out a very nice clean square wave. With their very definite rise and fall times, the timing of those signals is very precise. That's not important for speed signals, but it is for position sensors like the crankshaft position sensor and the camshaft position sensor.

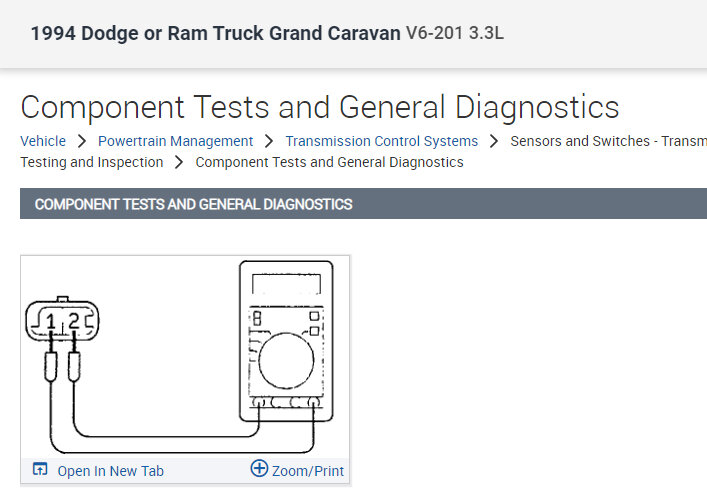

To test a speed sensor, you need to connect an oscilloscope such as is used in tv repair, and you must be able to run the vehicle in gear. There's a much easier and less complicated way. That is to simply use a scanner to view live data, and see what it shows for the engine speed, road speed, or wheel speed. If the computer can read it, the sensor is working.

I've been following along to learn the solution. That's why I noticed too much time is being spent on trying to do a test that can't be done.

By the way, a lot of competent do-it-yourselfers also figure out they need to read these signals with a digital voltmeter set on AC Volts. That won't work either except to tell you if there's something vs. Nothing. Digital meters are designed to read 60 hertz voltages as found in house wiring. Some expensive meters will be accurate up to 400 hertz for military use. The front tone ring on a mid '90s Caravan brake rotor has 57 teeth so the sensor will generate 57 hertz when the wheel is spinning at one revolution per second. Since speed is a factor in signal strength, the signal voltage is very low at that speed, and will likely be too low to be read by the computer. That, in part, is why all ABS systems deactivate below 9 or 15 mph. At faster rotational speeds, the signal voltage will increase, but the meter loses its response, and will likely show a lower voltage.

I should correct myself too in that you CAN measure the resistance of a two-wire speed sensor as it is just a long piece of wire wrapped around a magnet. It's extremely rare to have one read the wrong resistance value, so it isn't really necessary to know the specs. Those specs are provided in service manuals, but only for reference, and for training purposes. You're looking for infinite resistance, meaning an open circuit, to show if one end of the wire is broken off its terminal internally. If you find anything other than an open circuit, the wire is okay. Common or typical values range from 100 ohms to as much as 750 ohms, (that I have memorized), for the distributor pickup on my '78 LeBaron. You can't get to that coil of wire to measure its resistance in a three-wire sensor. The only thing you can do with those is live testing by running something to make the sensor generate its signal.

While not real common, a speed sensor can fail intermittently and work at other times, depending on temperature, vibration, or flexing wires like with ABS wheel speed sensors. A more common source of intermittent dropouts of the signal on some sensor designs is too large of an air gap. For most designs, that is set by the design of the mounting bracket, but there have been some that need special procedures to set that air gap.

Hope that helps you move ahead to solve any remaining problems.

Saturday, May 11th, 2024 AT 8:18 PM