See if this helps:

1) Set crankshaft sprocket to TDC by aligning the sprocket with the arrow on the oil pump housing.

2) Set camshafts timing marks so that the exhaust camshaft sprocket is a half notch below the intake camshaft sprocket.

Ensure that the arrows on both camshaft sprockets are facing up.

3) Starting at the crankshaft, go around the water pump sprocket, idler pulley, camshaft sprockets and then around the tensioner.

4) Move the exhaust camshaft sprocket counterclockwise to align marks and take up belt slack.

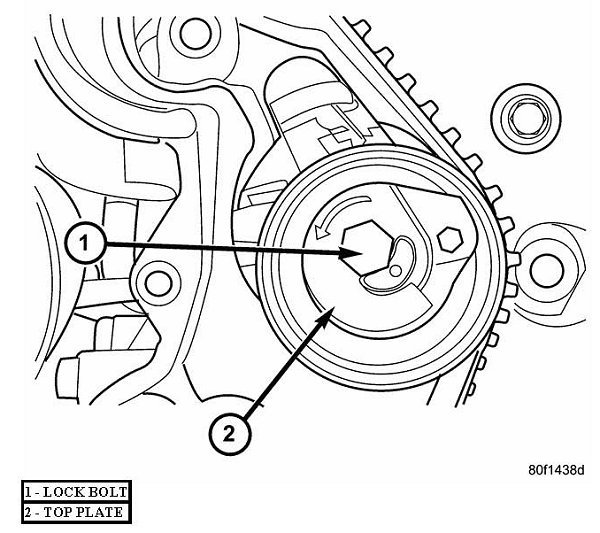

5) Insert a 6mm Allen wrench into the hexagon opening located on the top of the belt tension-er pulley. Rotate the top plate counterclockwise. The tension-er pulley will move against the belt and the tension-er setting notch will eventually start to move clockwise. Watching the movement of the setting notch, continue rotating the top plate counterclockwise until the setting notch is aligned with the spring tang. Using the Allen wrench to prevent the top plate from moving, torque the tension-er lock bolt to 25 Nm (220 in. Lbs). Setting notch and spring tang should remain aligned after lock bolt is torqued.

6)Remove Allen wrench and torque wrench.

NOTE : Re-positioning the crankshaft to the TDC position must be done only during the clockwise rotation movement. If TDC is missed, rotate a further two revolutions until TDC is achieved. Do not rotate crankshaft counterclockwise as this will make verification of proper tension-er setting impossible.

7) Rotate the crankshaft clockwise two complete revolutions manually for seating of the belt, until the crankshaft is re-positioned at the TDC position. Verify that the camshaft and crankshaft timing marks are in proper position.

(alldata)

Monday, December 4th, 2017 AT 5:50 PM