Friday, February 4th, 2022 AT 4:00 PM

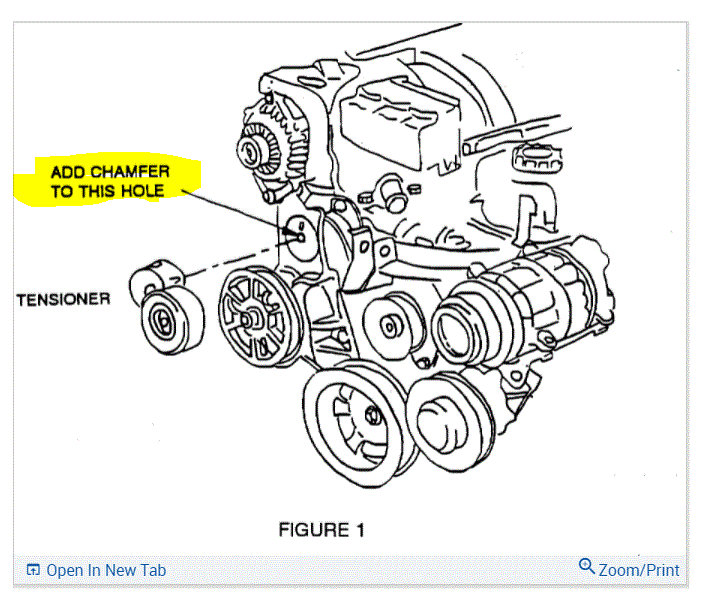

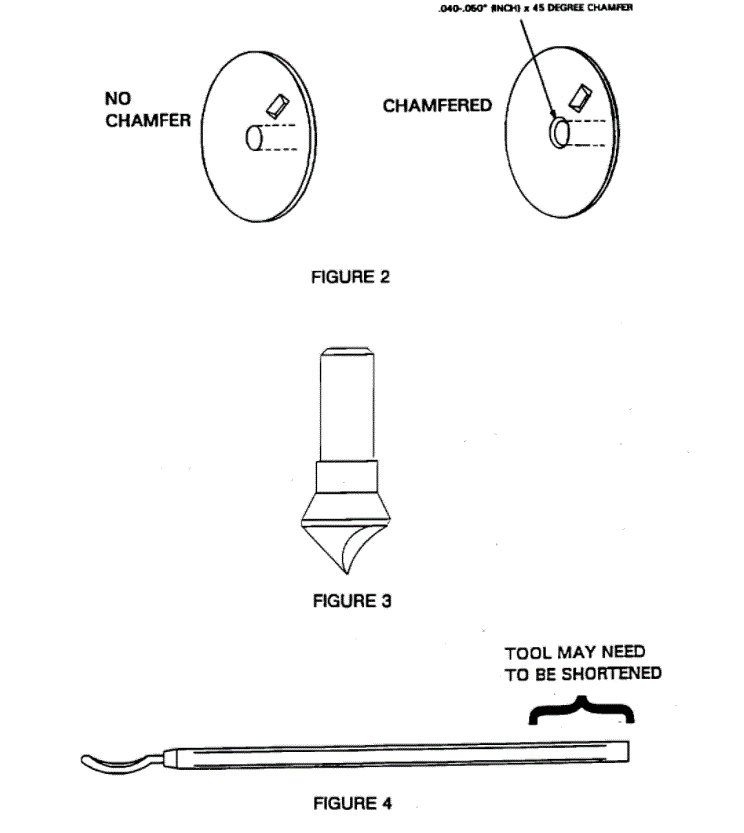

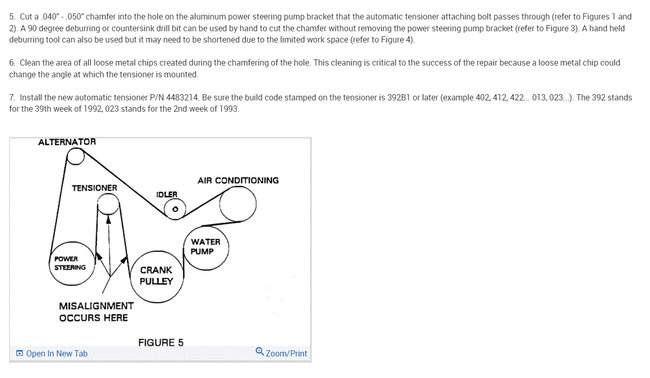

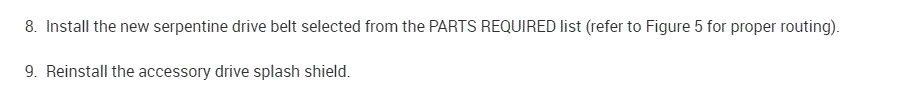

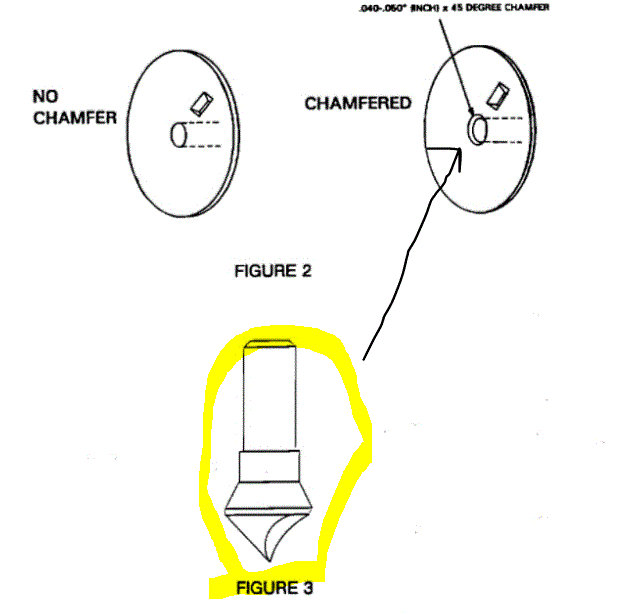

I'm driving a 1993 Newyorker. There's been a squeak from the belt area that almost sounds like a chirp. I've replaced the alternator. The belts been replaced (although maybe could have received damage since because of a missing mud guard during winter and also a hole in my radiator from hitting a deer) I've replaced the water pump and tensioner Pully (not the housing) and have cleaned all pulleys. I suspect that maybe it could be the tensioner pulley housing that's losing tension as the motors running causing it to intermittently chirp but I have had other ideas that weren't, and I don't want to move forward I thought I'd ask first what the best way to diagnose it from here is. Thanks, John