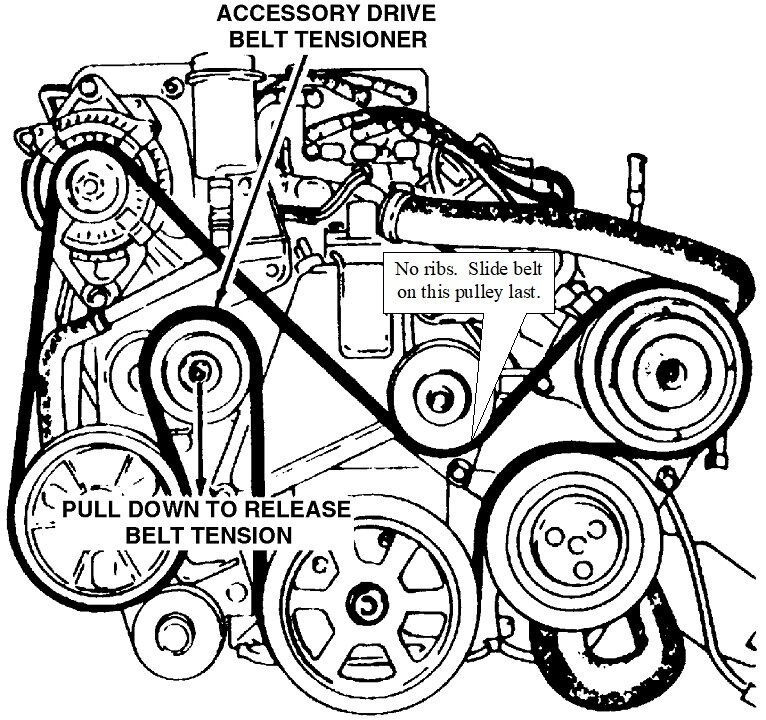

Hi guys. Sorry that I wasn't here yesterday. Ken mentioned the belt routing. There's two things I've seen or done myself that you might want to check for. The first is a coworker ran the belt on the bottom, or wrong side of the water pump pulley. The clue is that pulley is smooth, but the ribbed side of the belt was running on it. I mistakenly tried to run the belt from the crankshaft pulley around the bottom of the power steering pump pulley, then the wrong way around the tensioner pulley. The ribbed and smooth sides were still on the pullies the correct way, but it didn't work.

Another thing I've done too often is not having the ribbed side all the way on one of the pullies. This is easiest to do on the power steering pump pulley because you can't really see it, even from the bottom because there's a large splash shield under it. You gotta go by feel from on top. If the belt is partially up on the lip, that is more than enough for it to appear to be too short.

For future reference, if you have to replace the tensioner, it is easiest to do from up on top, by feel. You will likely need two different 15mm box wrenches. Space is limited, so one wrench might not sit on the nut. I had Craftsman wrenches and a coworker had Snapon wrenches. We'd borrow them back and forth for this job. One would go on the nut and loosen it, but not far enough to get another bite with the same wrench. That's where the second, different wrench came in. Once loose, the nut can be run off by hand.

Also, I didn't catch it earlier, but I see you replaced the bearing in the tensioner. I didn't know that was even possible. Normal procedure is to replace the entire assembly. Wear takes place in the pivot and lets the arm and pulley sit at an angle. That makes the belt slide off, but the clue leading up to that is a noticeable belt squeal. By being tipped or turned, the belt slides across the pulley as it goes around it. That's what sets up the squeal. An additional clue is the squeal will go away for a few seconds when you dribble water on the smooth side while the engine is running.

I've felt that little give you described when tugging on the arm. Two things come to mind. One is corrosion in the arm's pivot, and you're overcoming the extra force needed to rotate it that last little bit. Something else to consider, if the assembly was removed, is the locating tab might not be seated in the notch on the engine. As you run the nut down by hand, lift or move the tensioner until you feel the tab drop into the notch. As you continue to tighten the nut, you can push the assembly up and down to feel the tab is seated. It may be hard to see, but the clue is the pulley is not straight in line with the others.

I noticed you mentioned a long 15mm wrench too. That is not needed and, in fact, might make the job a little more difficult. I used a regular combination wrench with the box end on the bolt head, then I hooked another box wrench onto one ear of the open end for more leverage. Two wrenches end to end is more than enough leverage, and you can turn the second one of to the side a little, then hook it on the metal strap on the right strut tower that holds the AC lines. That keeps the tensioner in the released orientation while you replace one of the other parts. When these cars were new, they had a lot of trouble with the water pumps becoming noisy, causing a buzzing noise. Replacement was uncommonly easy after belt tension was released. This way you don't have to remove the belt. Just do the service, then unhook and remove the wrenches.

Wednesday, January 22nd, 2025 AT 5:57 PM