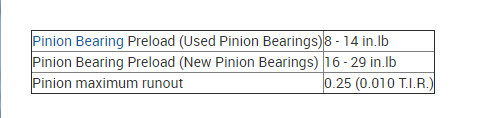

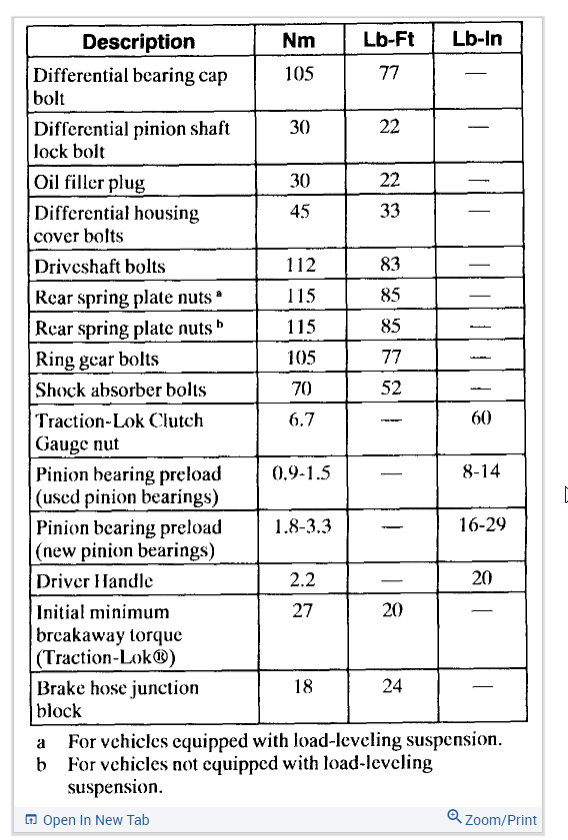

I attached the specs for the rear end. This should be all of them.

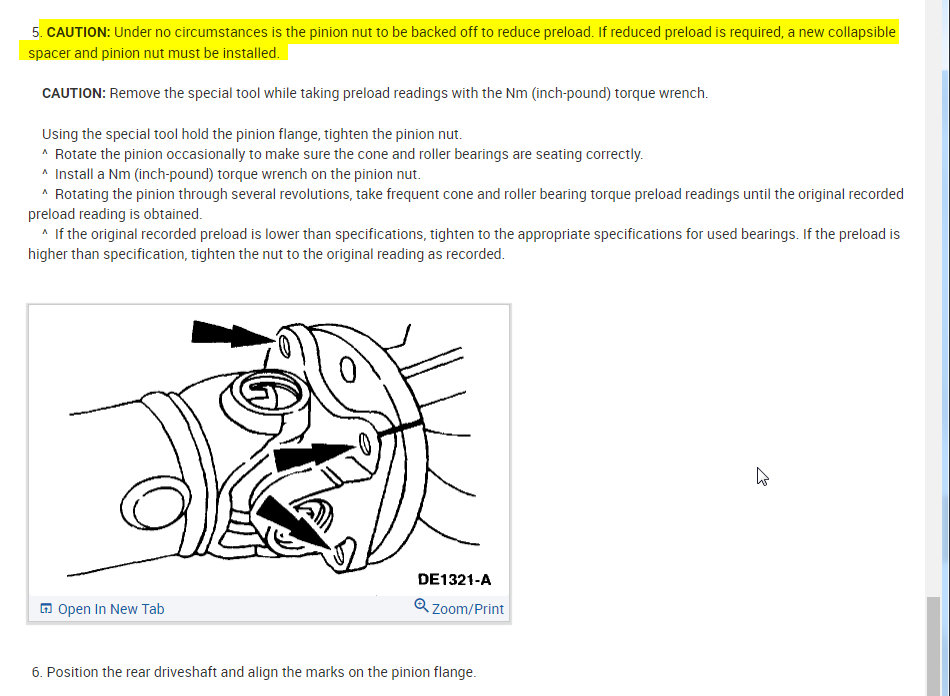

As for the preload. No this can be done with the carrier in place. Basically it is done anytime the pinion comes out or if you remove the pinion nut. You can reuse the crush sleeve if you are not taking the pinion out like if you are just replacing the pinion seal. This would just require you to measure the turning torque in inch pounds before you take the nut off. Then you tighten the pinion nut back to this inch pound. If you go to far, you cannot loosen the nut to reach the proper torque because you have crushed the sleeve more and it will loosen up and cause noise and other issues.

Let me know if you have other questions. Thanks

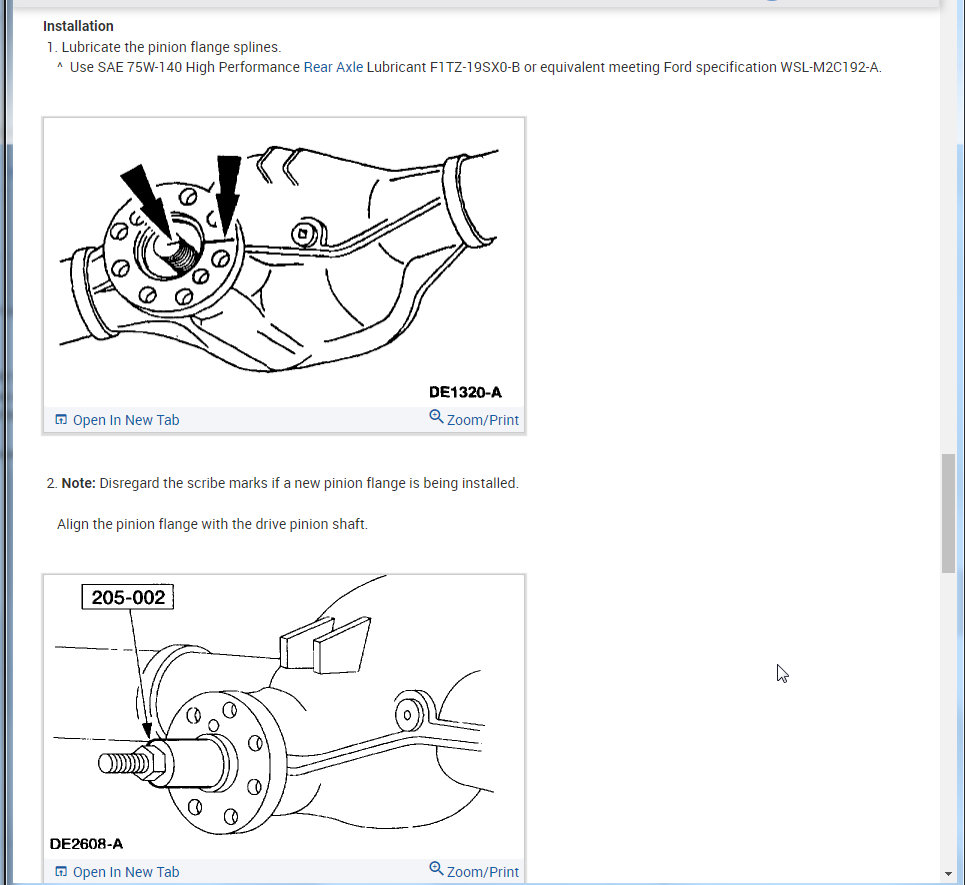

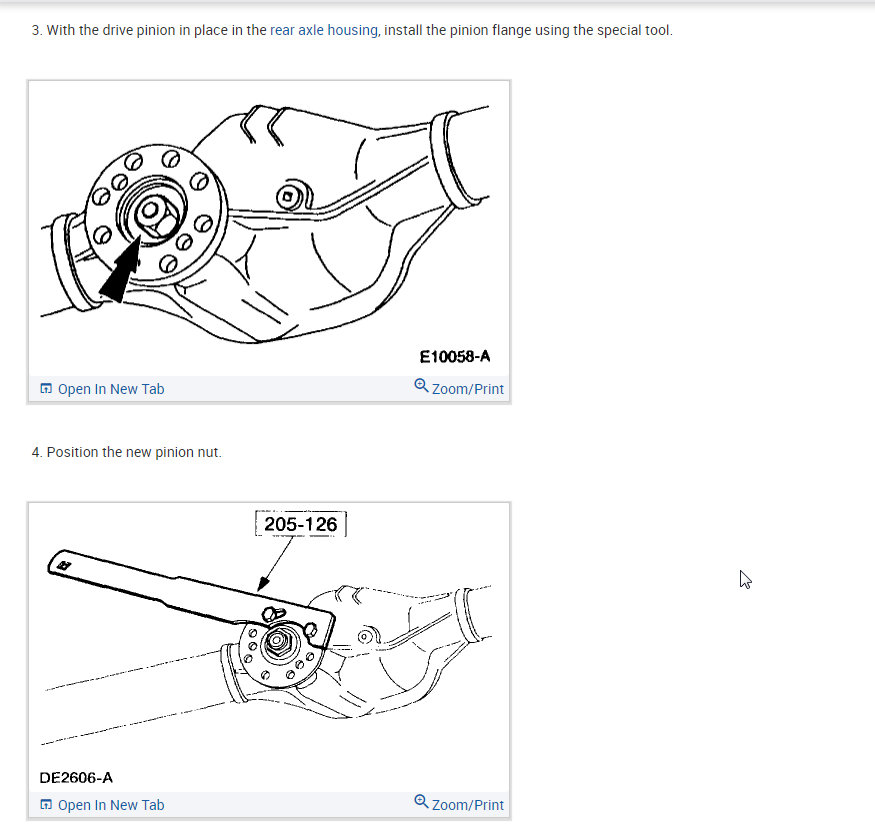

Image (Click to make bigger)

Monday, May 17th, 2021 AT 2:32 PM