Okay, it's one of the steel lines on the rack. You may be able just to replace that steel line. However, here are the directions for rack replacement. The attached pictures correlate with the directions.

_________________________________________________

Removal and Installation

Vehicle Steering and Suspension Steering Steering Gear Service and Repair Procedures Removal and Installation

REMOVAL AND INSTALLATION

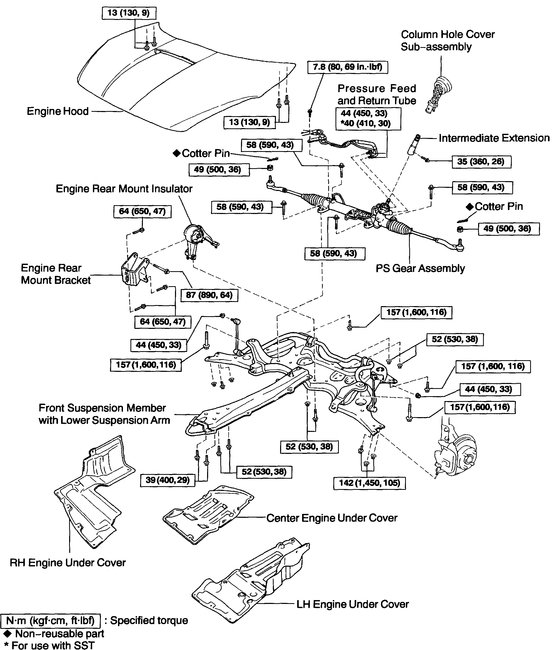

Part 1 Of 3

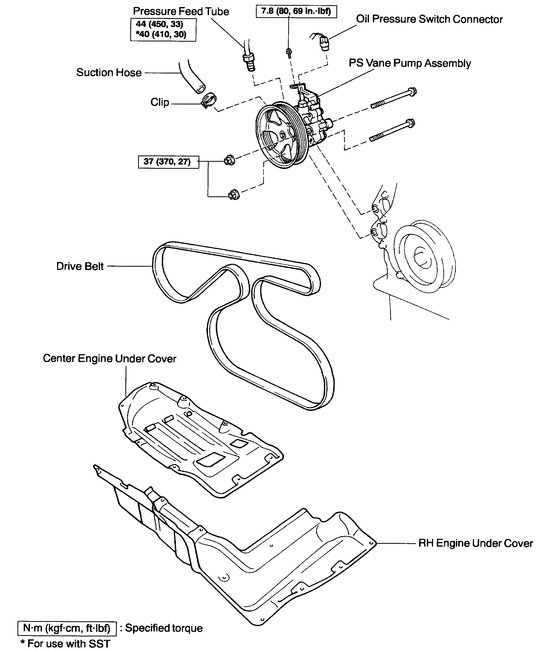

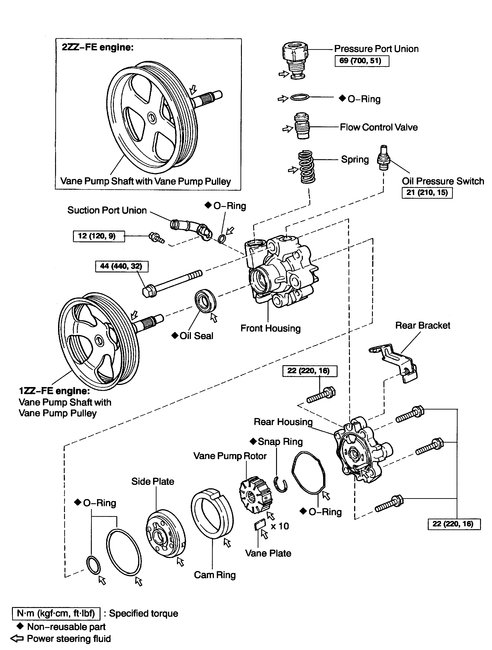

pic 1

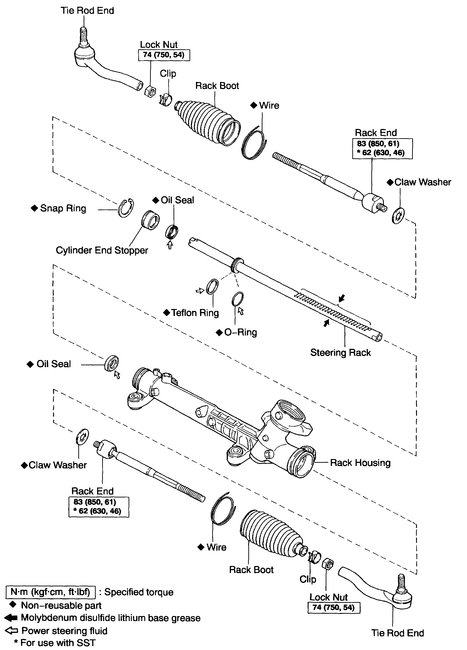

Part 2 Of 3

pic 2

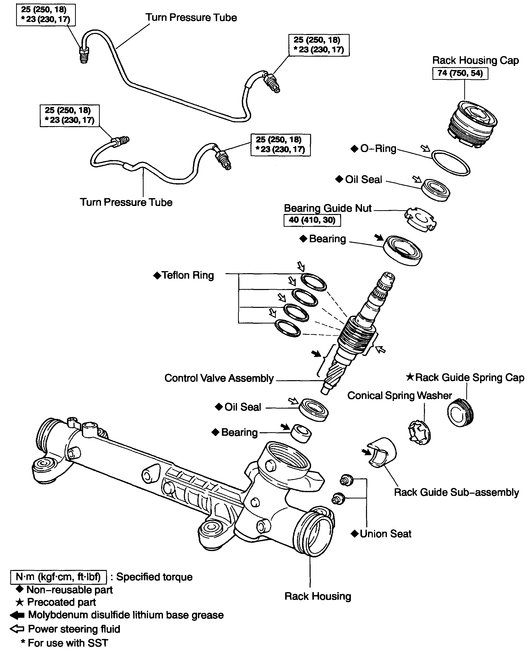

Part 3 Of 3

pic 3

REMOVAL

NOTICE: Remove the steering wheel assembly before the steering gear removal, because there is possibility of breaking of the spiral cable.

1. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

2. REMOVE STEERING WHEEL PAD

3. REMOVE STEERING WHEEL

4. REMOVE RH, CENTER AND LH ENGINE UNDER COVERS

5. DISCONNECT RH AND LH TIE ROD ENDS

6. DISCONNECT NO. 2 INTERMEDIATE SHAFT ASSEMBLY

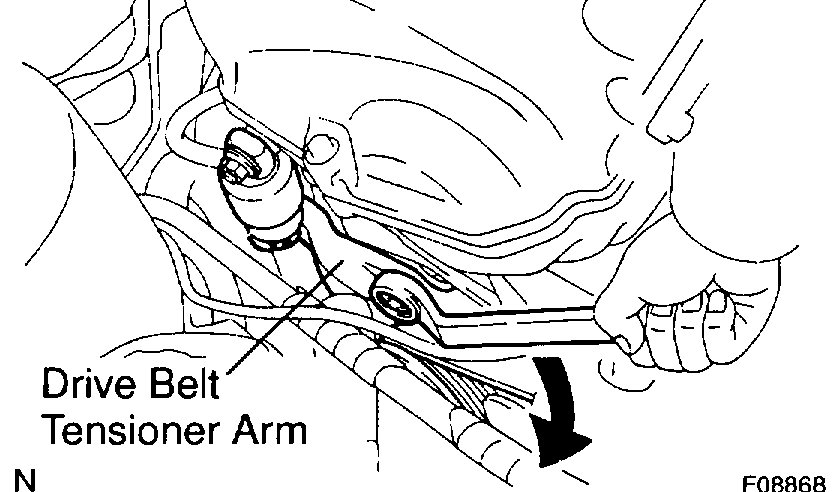

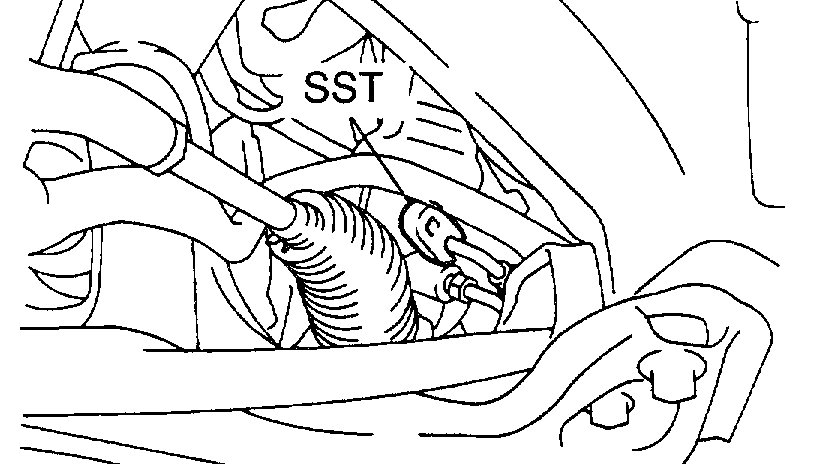

pic 4

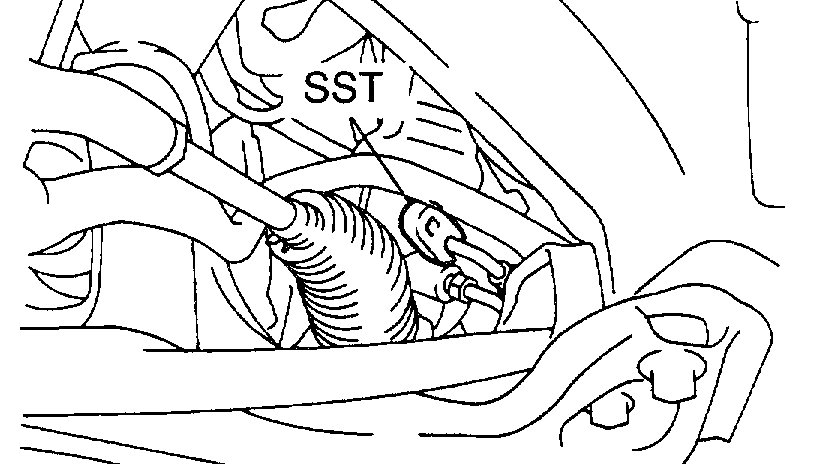

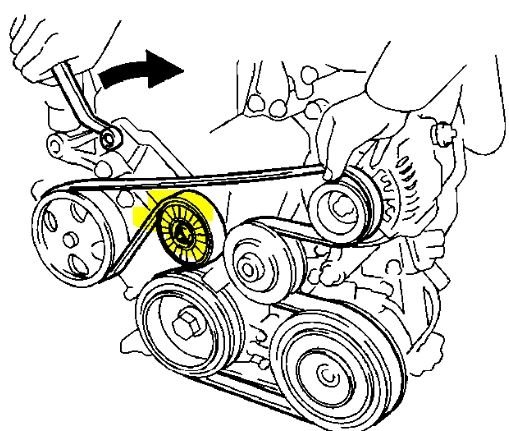

7. DISCONNECT PRESSURE FEED AND RETURN TUBES

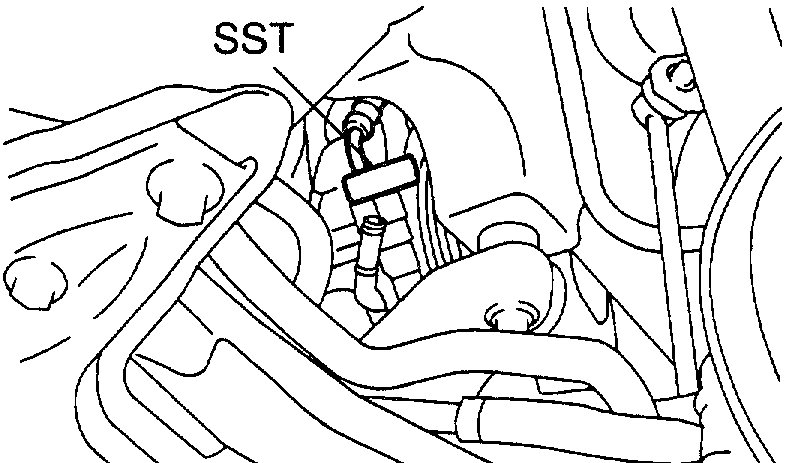

Using SST, disconnect the pressure feed and return tubes.

SST 09023-38400

pic 5

8. DISCONNECT TUBE CLAMP

Remove the bolt and disconnect the tube clamp.

9. DISCONNECT COLUMN HOLE COVER ASSEMBLY

10. REMOVE ENGINE HOOD

pic 6

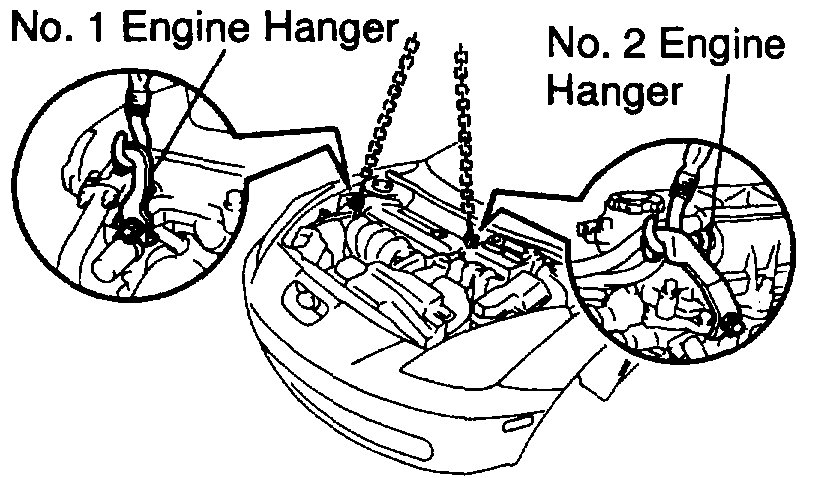

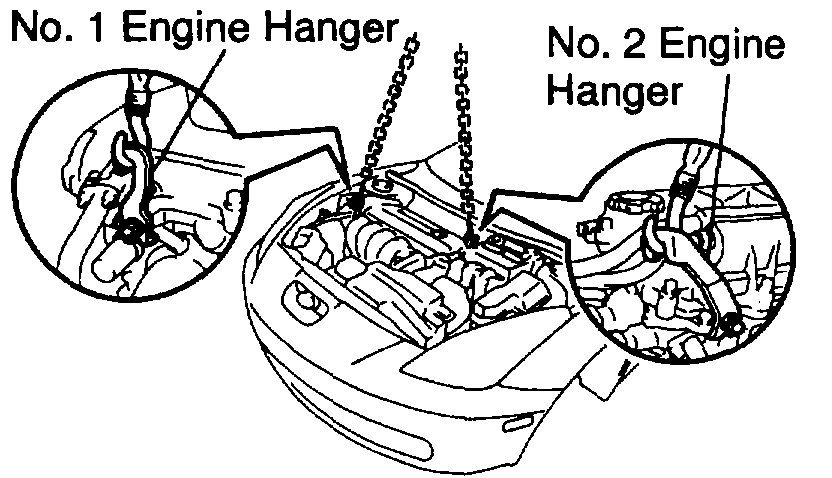

11. ATTACH ENGINE SLING DEVICE TO ENGINE HANGERS

a. Remove the 4 bolts and No. 2 cylinder head cover.

B. Disconnect the PCV hoses from the cylinder head cover.

C. Install the No.1 and No. 2 engine hangers in the correct direction.

1Z-FE Engine: Part No:

No.1 engine hanger: 12281-22021

No.2 engine hanger: 12281-15040 or 12281-15050

Bolt: 91512-B1016

Torque: 38 Nm (388 kgf-cm, 28 ft. Lbs.)

2ZZ-FE Engine:

Part No:

No.1 engine hanger: 12281-88600

No.2 engine hanger: 12282-88600

Bolt: 91512-61020

Torque: 38 Nm (388 kgf-cm, 28 ft. Lbs.)

d. Attach the engine sling device to the engine hangers.

CAUTION: Do not attempt to hang the engine by hooking the chain to any other part.

12. DISCONNECT LOWER BALL JOINT FROM LOWER SUSPENSION ARM

13. DISCONNECT STABILIZER BAR

a. Remove the nut and disconnect the stabilizer bar.

B. Employ the same manner described above to the other side.

Pic 7

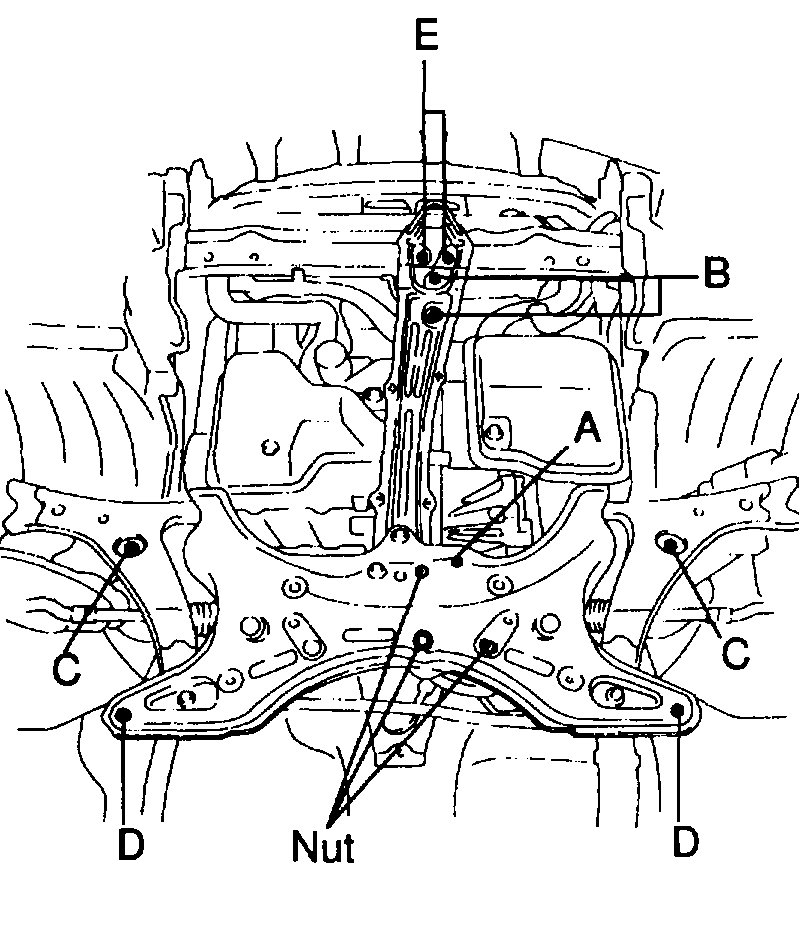

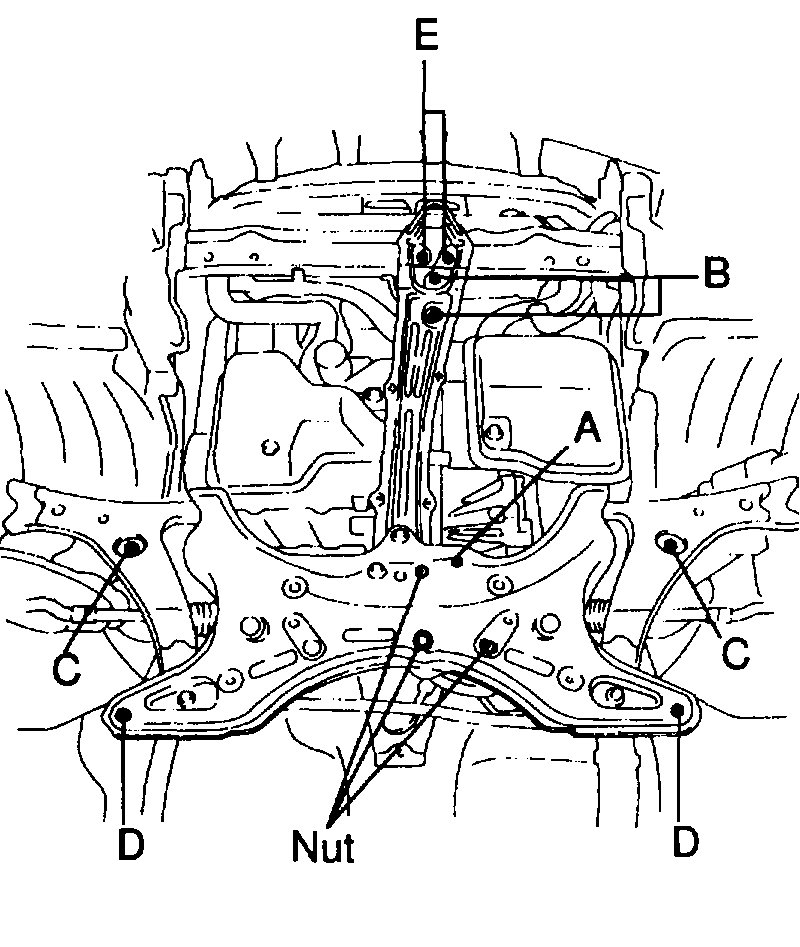

14. DISCONNECT ENGINE REAR MOUNT INSULATOR AND FRONT SUSPENSION MEMBER

Remove the bolt (bolt A) and 3 nuts, and disconnect the engine rear mount insulator and front suspension member.

15. DISCONNECT ENGINE FRONT MOUNT INSULATOR AND FRONT SUSPENSION MEMBER

Remove the 2 bolts (bolt B) and disconnect the engine front mount insulator and front suspension member.

16. SUPPORT FRONT SUSPENSION MEMBER WITH LOWER SUSPENSION ARM

Using a transmission jack, support the front suspension member with lower suspension arm.

17. REMOVE FRONT SUSPENSION MEMBER WITH LOWER SUSPENSION ARM AND PS GEAR ASSEMBLY

Remove the 6 bolts (bolt C, D and E) and front suspension member with lower suspension arm and PS gear assembly.

Pic 8

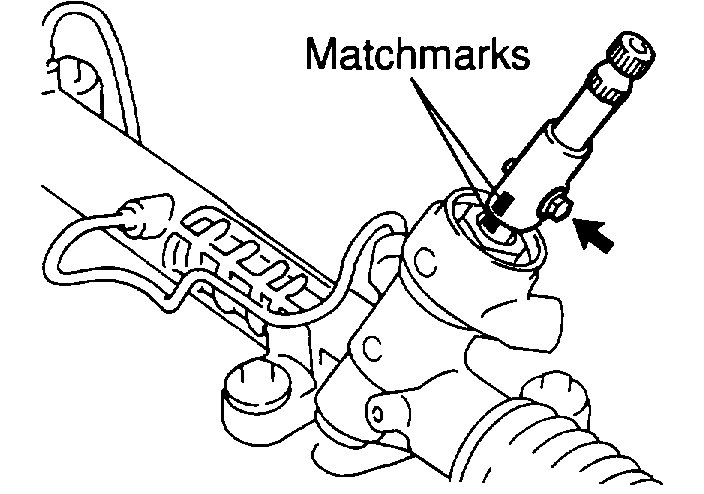

18. REMOVE PS GEAR ASSEMBLY

a. Remove the 4 bolts and PS gear assembly from the front suspension member.

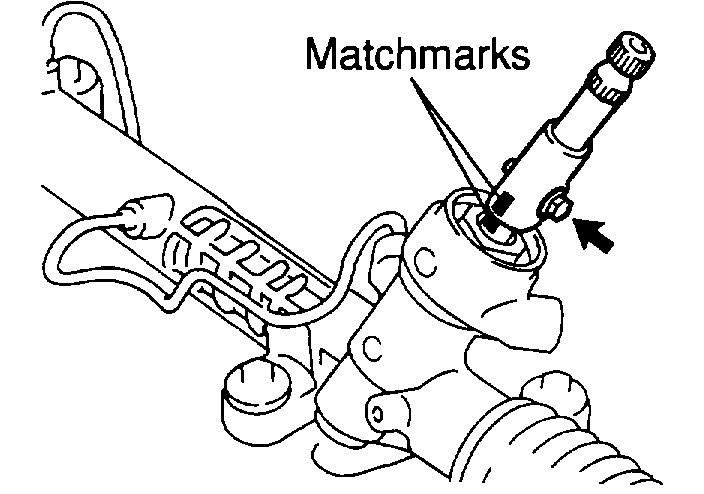

B. Place matchmarks on the intermediate extension and control valve shaft.

C. Remove the bolt and intermediate extension.

19. REMOVE ENGINE REAR MOUNT INSULATOR AND ENGINE REAR MOUNT BRACKET

a. Remove the through bolt and engine rear mount insulator.

B. Remove the 3 bolts and engine rear mount bracket.

INSTALLATION

1. INSTALL ENGINE REAR MOUNT INSULATOR AND ENGINE REAR MOUNT BRACKET

a. Install the engine rear mount bracket with the 3 bolts.

Torque: 64 Nm (650 kgf-cm, 47 ft. Lbs.)

b. Install the engine rear mount insulator with the through bolt.

Torque: 87 Nm (890 kgf-cm, 64 ft. Lbs.)

pic 9

2. INSTALL PS GEAR ASSEMBLY

a. Align the matchmarks on the intermediate extension and control valve shaft.

B. Install the bolt.

Torque: 35 Nm (360 kgf-cm, 26 ft. Lbs.)

c. Install the PS gear assembly with the 4 bolts to the front suspension member.

Torque: 58 Nm (590 kgf-cm, 43 ft. Lbs.)

pic 10

3. INSTALL FRONT SUSPENSION MEMBER WITH LOWER SUSPENSION ARM AND PS GEAR ASSEMBLY

Install the front suspension member with lower suspension arm and PS gear assembly with the 6 bolts (bolt C, D and E).

Torque:

Bolt C: 157 Nm (1,600 kgf-cm, 116 ft. Lbs.)

Bolt D: 157 Nm (1,600 kgf-cm, 116 ft. Lbs.)

Bolt E: 39 Nm (400 kgf-cm, 29 ft. Lbs.)

4. CONNECT ENGINE FRONT MOUNT INSULATOR AND FRONT SUSPENSION MEMBER

Connect the engine front mount insulator and front suspension member with the 2 bolts (bolt B).

Torque: 52 Nm (530 kgf-cm, 38 ft. Lbs.)

5. CONNECT ENGINE REAR MOUNT INSULATOR AND FRONT SUSPENSION MEMBER

Connect the engine rear mount insulator and front suspension member with the bolt (bolt A) and 3 nuts.

Torque: 52 Nm (530 kgf-cm, 38 ft. Lbs.)

6. CONNECT STABILIZER BAR

a. Connect the stabilizer bar with the nut.

Torque: 44 Nm (450 kgf-cm, 33 ft. Lbs.)

b. Employ the same manner described above to the other side.

7. CONNECT LOWER BALL JOINT TO LOWER SUSPENSION ARM

pic 11

8. DISENGAGE ENGINE SLING DEVICE FROM ENGINE HANGERS

a. Disengage the engine sling device from the engine hangers.

B. Remove the No. 1 and No. 2 engine hangers.

C. Connect the PCV hoses to the cylinder head cover.

D. Install the No. 2 cylinder head cover with the 4 bolts.

9. INSTALL ENGINE HOOD

10. CONNECT COLUMN HOLE COVER SUB-ASSEMBLY

pic 12

11. CONNECT TUBE CLAMP

Connect the tube clamp with the bolt.

Torque: 7.8 Nm (80 kgf-cm, 69 inch lbs.)

pic 13

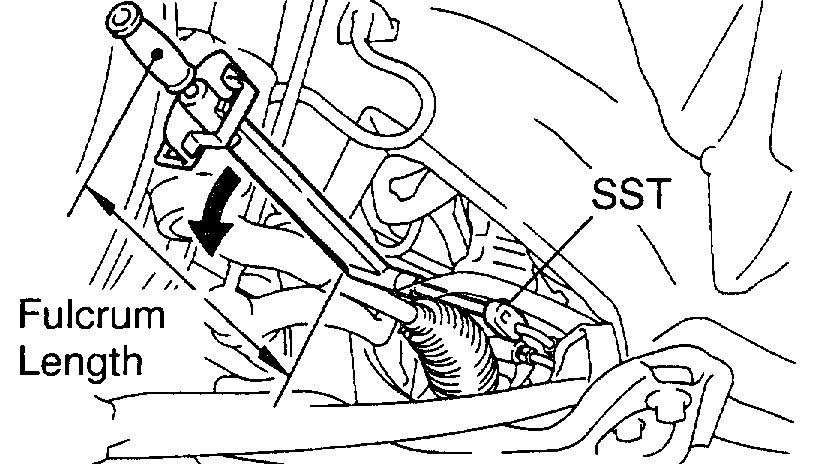

12. CONNECT PRESSURE FEED AND RETURN TUBES

Using SST, connect the pressure feed and return tubes.

SST 09023-38400

Torque: 40 Nm (410 kgf-cm, 30 ft. Lbs.)

HINT:

Use a torque wrench with a fulcrum length of 345 mm (13.58 inch).

This torque value is effective in case that SST is parallel to a torque wrench.

13. CONNECT NO. 2 INTERMEDIATE SHAFT ASSEMBLY

14. CONNECT RH AND LH TIE ROD ENDS

15. INSTALL RH, CENTER AND LH ENGINE UNDER COVERS

16. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

HINT: Do it with the front of the vehicle jacked up.

17. CENTER SPIRAL CABLE

18. INSTALL STEERING WHEEL

a. Align the matchmarks on the steering wheel and steering column main shaft.

B. Temporarily tighten the steering wheel set nut.

19. BLEED POWER STEERING SYSTEM

20. CHECK STEERING WHEEL CENTER POINT

21. TORQUE STEERING WHEEL SET NUT

Torque: 50 Nm (510 kgf-cm, 37 ft. Lbs.)

22. INSTALL STEERING WHEEL PAD

23. CHECK FRONT WHEEL ALIGNMENT

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

Let me know if this helps.

Take care,

Joe

Images (Click to make bigger)

Friday, July 19th, 2019 AT 7:14 PM