Welcome to 2CarPros.

This is a tough one here. Since it is reading lean, are you certain there is no slight exhaust leak? A leak at the manifold or before the converter will cause a lean condition on one bank.

Here is the diagnostic flow chart for the code. The attached pictures correlate with the directions.

_____________________

2001 Toyota Truck 4 Runner SR5 4WD V6-3.4L (5VZ-FE)

Troubleshooting

Vehicle ALL Diagnostic Trouble Codes ( DTC ) Testing and Inspection P Code Charts P0171 Troubleshooting

TROUBLESHOOTING

CIRCUIT DESCRIPTION

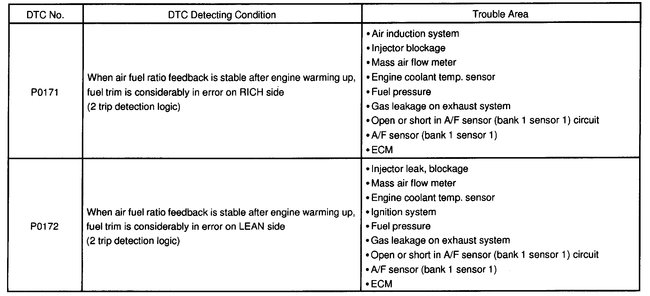

DTC Detecting Condition

pic 1

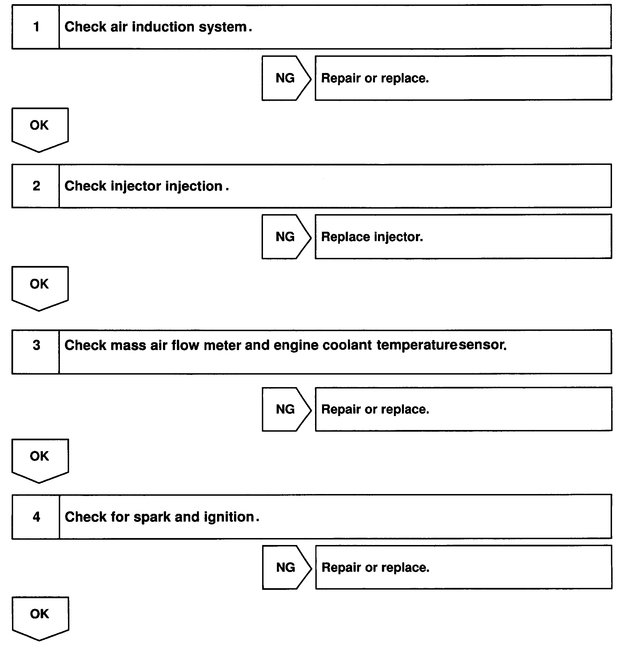

Steps 1 - 4

pic 2

Fuel trim refers to the feedback compensation value compared to the basic injection time. Fuel trim includes short-term fuel trim and long-term fuel trim.

Short-term fuel trim is the short-term fuel compensation used to maintain the air-fuel ratio at its ideal theoretical value. The signal from the A/F sensor is approximately proportional to the existing air-fuel ratio, and ECM comparing it with the ideal theoretical value, the ECM reduces fuel volume immediately if the air-fuel ratio is rich and increases fuel volume if it is lean.

Long-term fuel trim compensates for the deviation from the central value of the short-term fuel trim stored up by each engine tolerance, and the deviation from the central value due to the passage of time and changes of environment.

If both the short-term fuel trim and long-term fuel trim exceed a certain value, it is detected as a malfunction and the MIL lights up.

HINT:

- When the DTC P0171 is recorded, the actual air-fuel ratio is on the LEAN side. When DTC P0172 is recorded, the actual air-fuel ratio is on the RICH side.

- If the vehicle runs out of fuel, the air-fuel ratio is lean and DTC P0171 is recorded. The MIL then comes on.

- If the total of the short-term fuel trim value and long-term fuel trim value is within ± 35% (80 °C (176 °F) or more), the system is functioning normally.

- The A/F sensor (bank 1 sensor 1) output voltage and the short-term fuel trim value can be read using the OBD II scan tool or TOYOTA hand-held tester.

- The ECM controls the voltage of the AF1 - and AF1 - terminals of the ECM to the fixed voltage. Therefore, it is impossible to confirm the A/F sensor output voltage without OBD II scan tool or TOYOTA hand-held tester.

- OBD II scan tool (excluding TOYOTA hand-held tester) displays the one fifth of the A/F sensor output voltage which is displayed on the TOYOTA hand-held tester.

Wiring Diagram

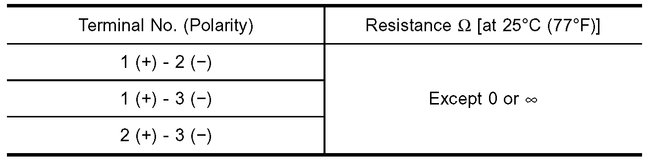

pic 3

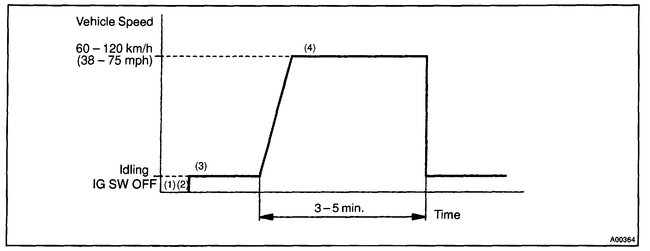

CONFIRMATION DRIVING PATTERN

pic 4

1. Connect the TOYOTA hand-held tester to the DLC3.

2. Switch the TOYOTA hand-held tester from the normal mode to the check mode.

3. Start the engine and warm it up with all the accessory switches OFF.

4. Drive the vehicle at 60 - 120 km/h (38 - 75 mph) and the engine speed at 1,600 - 3,200 rpm for 3 - 5 min.

HINT: If a malfunction exists, the MIL will light up during step (4).

NOTE:

- If the conditions in this test are not strictly followed, detection of the malfunction will not be possible.

- If you do not have a TOYOTA hand-held tester, turn the ignition switch OFF after performing steps (3) and (4), then perform steps (3) and (4) again.

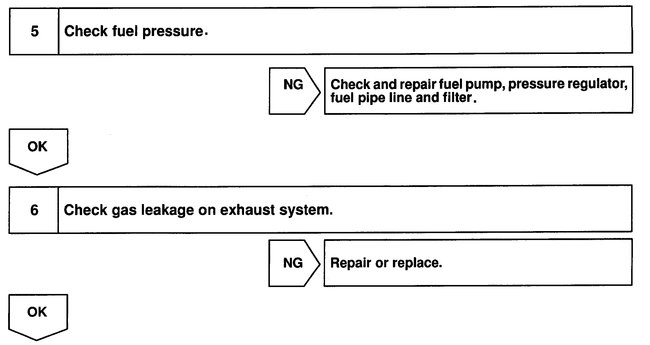

Steps 5 - 6

pic 5

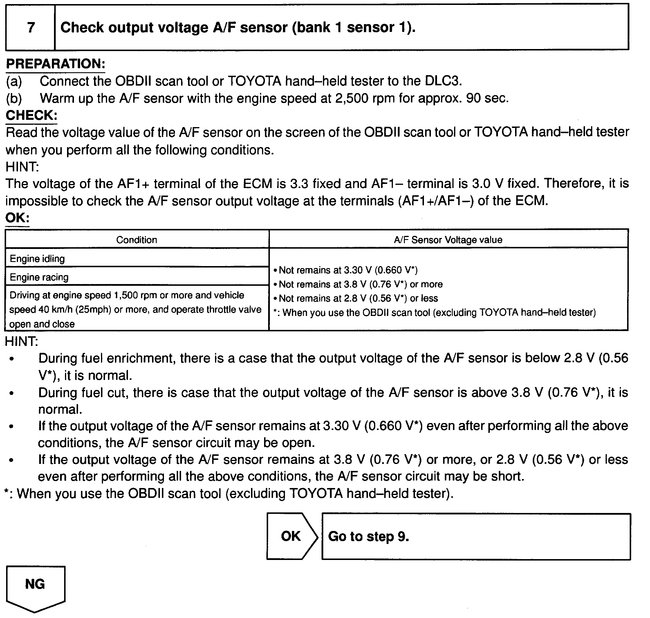

Step 7

pic 6

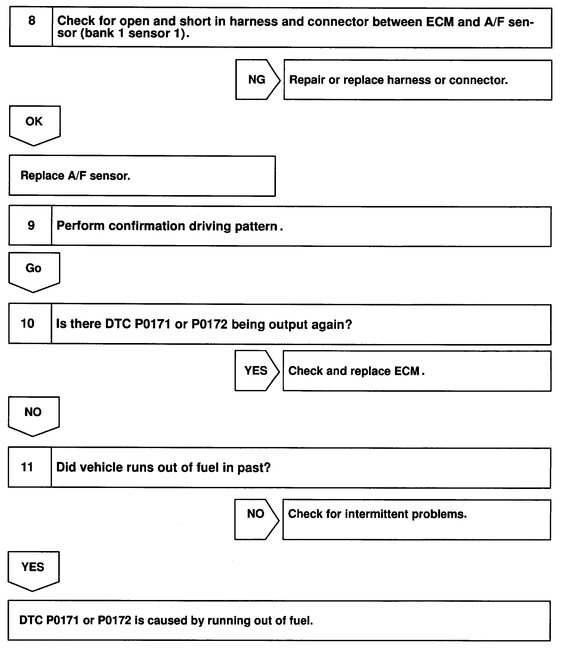

Steps 8 - 11

pic 7

INSPECTION PROCEDURE

Read freeze frame data using TOYOTA hand-held tester or OBD II scan tool. Because freeze frame records the engine conditions when the malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air-fuel ratio was lean or rich, etc. At the time of the malfunction.

CHECK FOR INTERMITTENT PROBLEMS

HINT: TOYOTA hand-held tester only:

By putting the vehicle's ECM in the check mode, 1 trip detection logic is possible instead of 2 trip detection logic and sensitivity to detect open circuits is increased. This makes it easier to detect intermittent problems.

A. Clear the DTCs (See step 2).

B. Set the check mode (See step 3).

C. Perform a simulation test.

D. Check the connector and terminal.

E. Handle the connector

____________

Let me know if that helps.

Joe

Images (Click to make bigger)

Friday, September 20th, 2019 AT 6:38 PM