Blindly replacing all the O2 sensors is not recommended. That's like replacing the driver's door window glass because the passenger's glass is broken. With every new sensor, the Engine Computer has to learn the personality, or characteristics of the signal it develops. Part of that strategy is to compare any one sensor signal to multiple other known values for similar driving or operating conditions. Replacing multiple sensors at the same time makes that very tedious and confusing by introducing multiple new variables.

The best example is when replacing a temperature sensor. The Engine Computer knows that after the engine has been off for at least six hours, the coolant temperature sensor and the intake air temperature sensor had better be reading the same temperature. When one of them is replaced, the signal voltage it develops might be as much as a couple of tenths of a volt different from the old sensor. That little difference means a really big deal to the computer. As soon as it sees that difference in readings when you turn on the ignition switch, it has ways to figure out which one has changed, then it learns what to expect from it. To add to the misery, it is not uncommon to get a good sensor that just doesn't work properly in some applications. You could actually be adding another defect to the list.

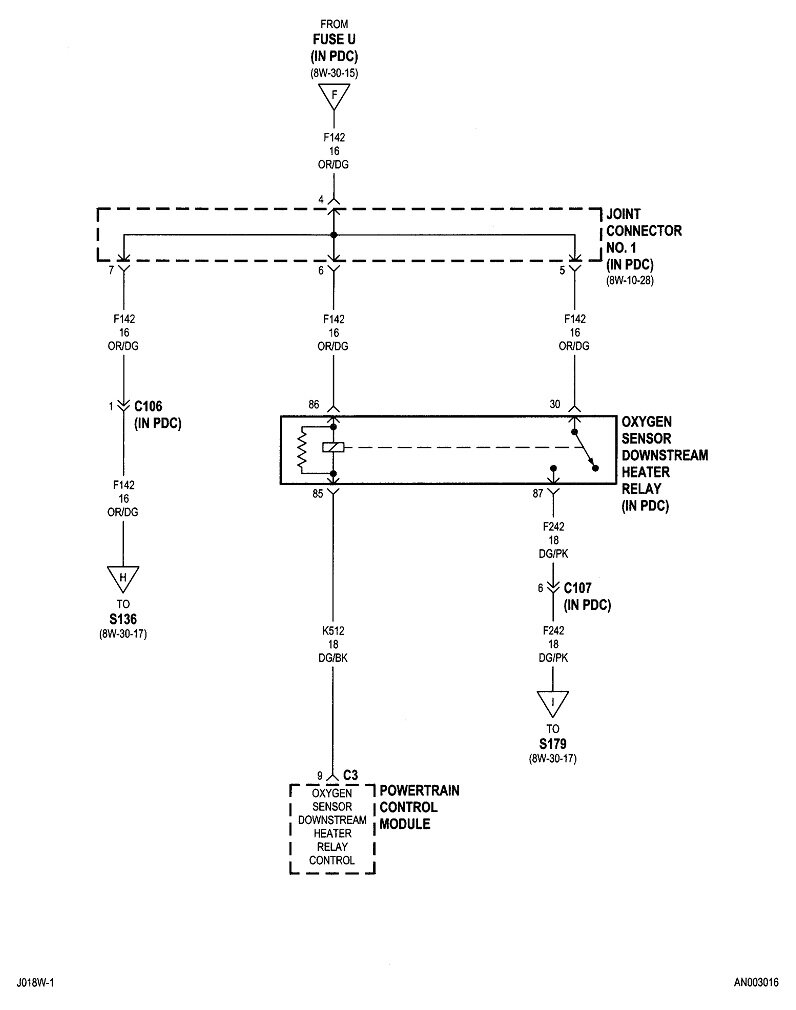

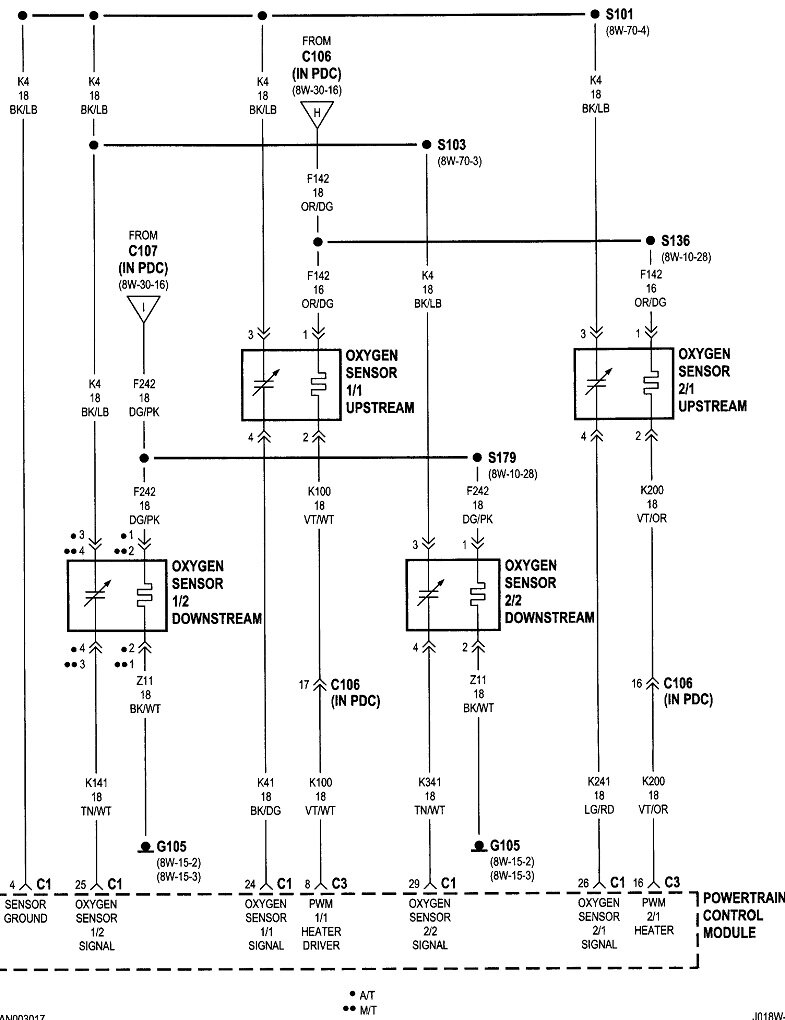

Instead, there's two ways I would approach this. The first one is to replace just one of the O2 sensors, erase all the fault codes, then see which ones set again. Normally when there's multiple O2 sensor failure codes, we look for something other than the sensor themselves to see what they have in common. If these two codes showed up at different times, over a long period of time, then it is indeed a good bet each one has failed, but if both codes showed up at the same time, look for a wiring issue first. In this case it's hard to figure out how these defects were detected. In the first diagram, the relay feeds 12 volts to all four heater circuits, but in the second diagram, it's only the two front, or upstream sensors that have their heater current monitored on individual circuits by the Engine Computer. The heaters for the two downstream sensors just go to ground with no way to monitor current flow through them. That means the Computer has to determine when there's a problem by watching their performance. Part of that involves seeing or creating a momentary change for the front sensor to detect, then watching to see if the rear sensor picks up the same thing or some other expected result. Any time the computer uses one sensor's signal to compare to that of another sensor, it knows those results can't be trusted when the first one has a fault code set. Some self-tests on the second sensor get suspended until the first problem is repaired. This is where, while not common, you could replace a front sensor for a fault code, then the self-tests resume and a defect is seen for the rear sensor and a new code is set for that one.

A second, different way to approach this is to address the fuel system leaks first. Under a very specific set of conditions, the Engine Computer commands the purge valve for the charcoal canister to open, then gas fumes get drawn out to be burned. At the same time the computer expects to see that show up in the O2 sensor readings. Incorrect purge flow, such as from a dry-rotted or blocked hose, would result in O2 sensor readings the computer doesn't expect to see. That might be misinterpreted as the sensor is not working properly. Repairing the leak, and eliminating the extra air coming in, might get the sensor to resume reading normally.

The two leak-related fault codes suggest there's a possibility this is one leak that started out small, then got worse. Besides the obvious loose gas cap, look for dry-rotted hoses between the gas tank and the charcoal canister, and from there to the engine. Also look for hose clamps that have rusted off. A more elusive cause is mineral deposits built up on the rubber gas cap seal. I've seen people clean that off with WD-40 to solve the leak.

Small leaks are trickier. Those can also be caused by the hoses and clamps, but another cause is leaking valves. There's no easy way to find them except by using a smoke machine. Those allow you to inject a white, non-toxic smoke at 2 psi into the vapor collection system, then you watch for where that smoke is sneaking out. These articles describe this better:

https://www.2carpros.com/articles/how-emission-control-systems-work

https://www.2carpros.com/articles/evap-system-code-repair

Let me know if this helps. Also, if the diagrams are too small to read, you can copy them into a typing program such as MS Word where they can be expanded, or I can cut them into smaller pieces that I can expand for you.

Images (Click to make bigger)

Friday, March 3rd, 2023 AT 5:10 PM