Welcome to 2CarPros

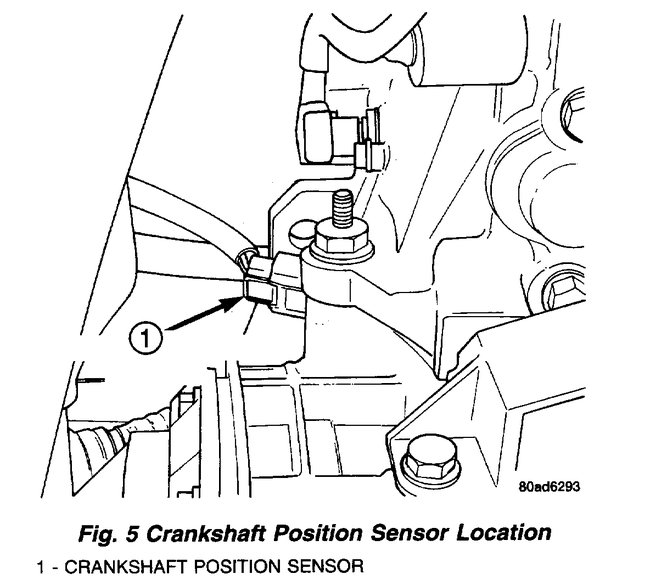

My first suspect is the crankshaft position sensor.

See Picture 1

The crankshaft sensor is located on the passengers side of the transmission housing, above the differential housing . The bottom of the sensor is positioned next to the drive plate. The sensor is a hall effect device combined with an internal magnet. It is also sensitive to steel within a certain distance from it.

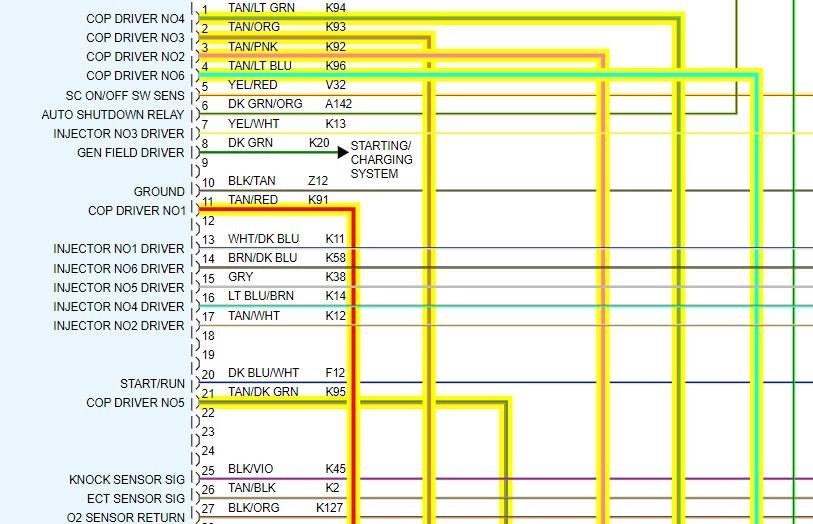

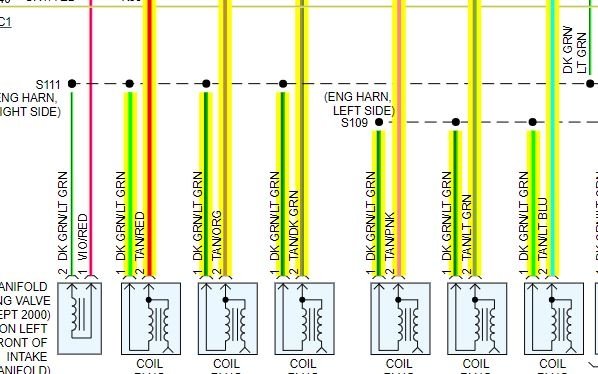

Engine speed and crankshaft position are provided through the crankshaft position sensor. The sensor generates pulses that are the input sent to the power-train control module (PCM). The PCM interprets the sensor input to determine the crankshaft position. The PCM then uses this position, along with other inputs, to determine injector sequence and ignition timing.

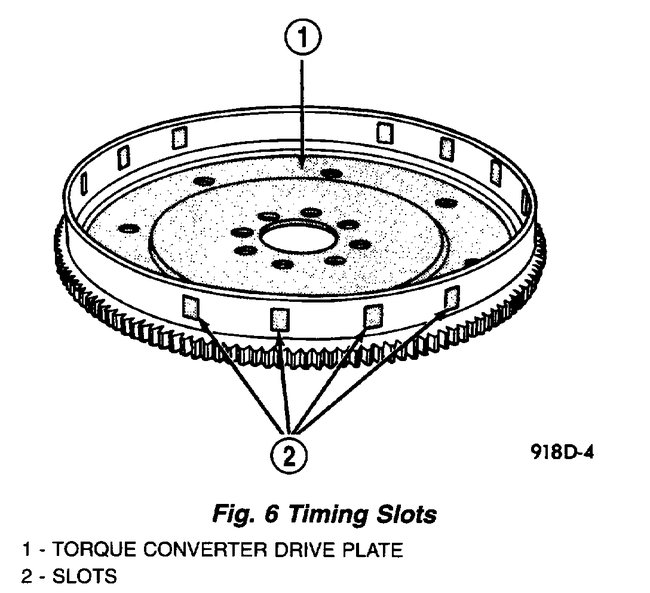

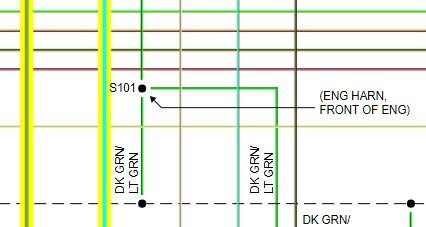

See Picture 2

The crankshaft position sensor detects slots cut into the transmission drive-plate extension. There are 3 sets of slots. Two sets contain 4 slots and one set contains 5 slots, for a total of 13 slots. Basic timing is set by the position of the last slot in each group. Once the Power-train Control Module (PCM) senses the last slot, it determines which piston will be next at TDC from the camshaft position sensor input. It may take the PCM one engine revolution to determine crankshaft position.

The PCM uses crankshaft position reference to determine injector sequence and ignition timing. Once the PCM determines crankshaft position, it begins energizing the injectors and coils in sequence.

The PCM uses the Crankshaft Position sensor to calculate the following:

- Engine rpm

- TDC number 1 and 4

- Ignition coil synchronization

- Injector synchronization

- Camshaft-to-crankshaft misalignment timing belt skipped 1 tooth or more diagnostic trouble code)

_____________________________

Now, since only two coils are getting power, I doubt it is a timing issue because you would still have spark, just at the wrong times. If you have access to a live data scanner, check to see if there is a good continuous RPM signal. If it is sporadic, replace the crankshaft position sensor.

Here are links that shows symptoms of a bad sensor and in general how one is replaced.

https://www.2carpros.com/articles/symptoms-of-a-bad-crankshaft-sensor

https://www.2carpros.com/articles/crankshaft-angle-sensor-replacement

______________________________________

Here are the directions specific to your vehicle for replacement.

REMOVAL

The crankshaft sensor is located on the passengers side of the transmission housing, above the differential housing. The bottom of the sensor sits above the drive plate.

1. Disconnect electrical connector from crankshaft position sensor.

2. Remove sensor mounting screw. Remove sensor.

INSTALLATION

The crankshaft sensor is located on the passengers side of the transmission housing, above the differential housing. The bottom of the sensor sits above the drive plate.

1. Install sensor and push sensor down until contact is made with the transmission case. While holding the sensor in this position, install and tighten the retaining bolt to 12 Nm (105 in. lbs.) torque.

2. Connect electrical connector to crankshaft position sensor.

____________________________________

Let me know if this helps. Also, when you remove the sensor, confirm nothing is damaged or corroded on the flywheel.

Take care,

Joe

Images (Click to make bigger)

Wednesday, March 20th, 2019 AT 7:12 PM