Hello,

P0118 for "Engine Coolant Temperature (ECT) Sensor Circuit High Open Problem". This can happen with a bad sensor, or the sensor is disconnected.

P0324 The knock sensor - this can happen when the sensor is bad or disconnected.

c342d means the throttle actuator is having an issue.

P0055 means the (ECM) has a problem for the third oxygen sensor on bank one.

c3064 is a generic code which should go away once all problems are fixed,

I have to say I think your PCM is bad because it would be very rare if all of these codes came on at once along with the speedo problem. To confirm the issue let's do a CAN scan which might show the bad PCM. Check out this guide and video:

https://www.2carpros.com/articles/can-scan-controller-area-network-easy

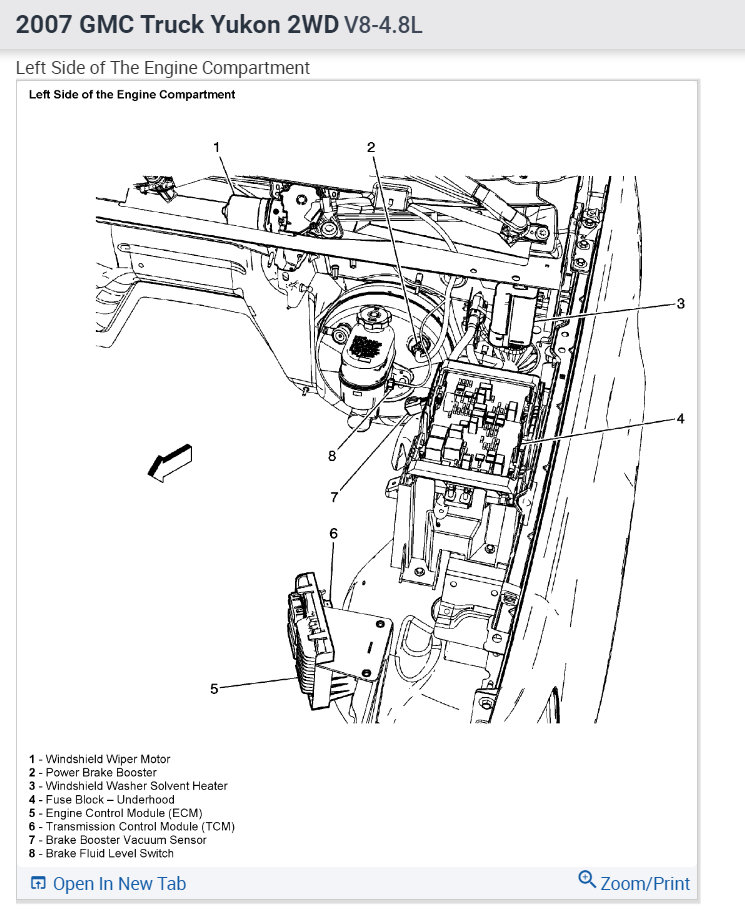

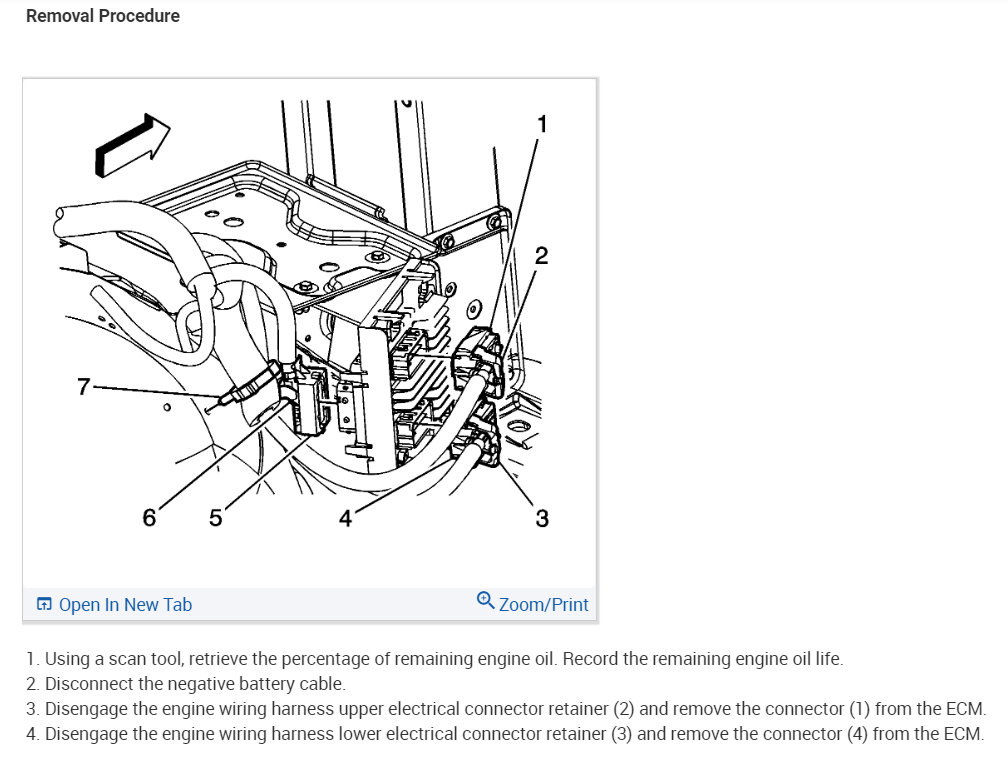

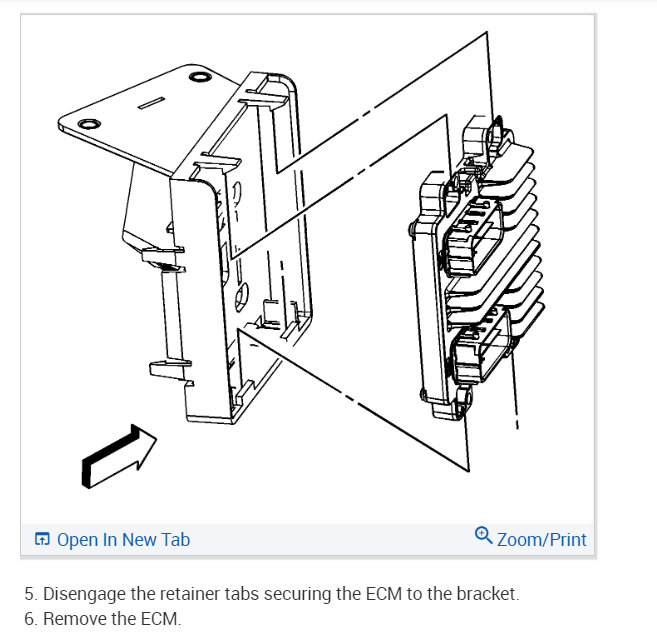

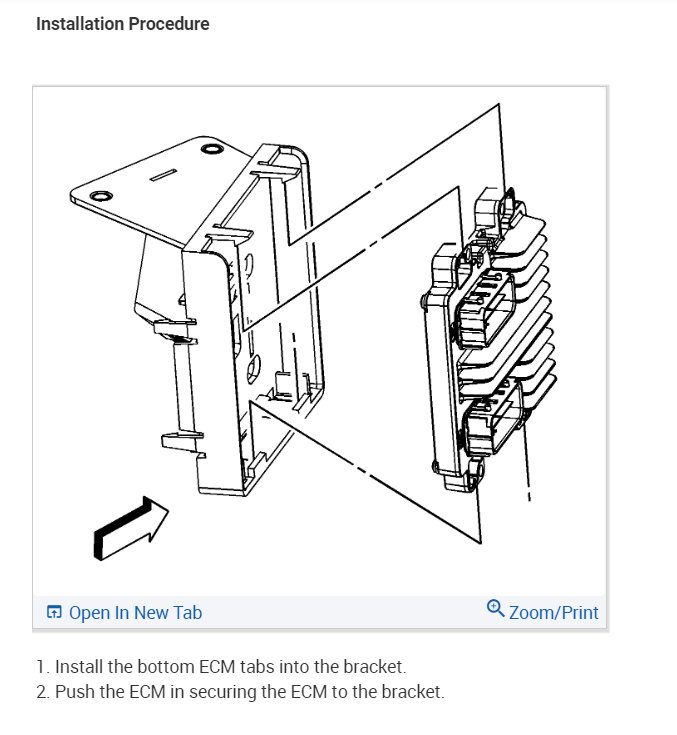

Here are the instructions on how to replace the PCM in the diagrams below. Instead of reprogramming etc. You can get a rebuilt PCM which is just plug and go.

https://carcomputerexchange.com

ENGINE CONTROL MODULE REPLACEMENT

Service of the engine control module (ECM) should consist of either replacement of the ECM or programming of the electrically erasable programmable read only memory (EEPROM). If the diagnostic procedures call for the ECM to be replaced, the replacement ECM should be checked to ensure that the correct part is being used. If the correct part is being used, remove the faulty ECM and install the new service ECM.

NOTE:

- Turn the ignition OFF when installing or removing the control module connectors and disconnecting or reconnecting the power to the control module (battery cable, powertrain control module (PCM)/engine control module (ECM)/transaxle control module (TCM) pigtail, control module fuse, jumper cables, etc.) in order to prevent internal control module damage.

- Control module damage may result when the metal case contacts battery voltage. DO NOT contact the control module metal case with battery voltage when servicing a control module, using battery booster cables, or when charging the vehicle battery.

- In order to prevent any possible electrostatic discharge damage to the control module, do no touch the connector pins or the soldered components on the circuit board.

- Remove any debris from around the control module connector surfaces before servicing the control module. Inspect the control module connector gaskets when diagnosing or replacing the control module. Ensure that the gaskets are installed correctly. The gaskets prevent contaminant intrusion into the control module.

- The replacement control module must be programmed.

IMPORTANT: It is necessary to record the remaining engine oil life. If the replacement module is not programmed with the remaining engine oil life, the engine oil life will default to 100 percent. If the replacement module is not programmed with the remaining engine oil life, the engine oil will need to be changed at 5 000 km (3,000 mi) from the last oil change.

Check out the diagrams (below). Let us know what happens and please upload pictures or videos of the problem.

Images (Click to make bigger)

Saturday, May 28th, 2022 AT 10:41 AM