Hi,

I could not find any definition for DTC P1537, is it the correct code?

DTC P0171 OR DTC P0174

Code Definition

DTC P0171: Adaptive Fuel Control

DTC P0174: Adaptive Fuel Control

Detection Condition

DTC P0171 indicates adaptive fuel control air/fuel ratio is too lean (right bank).

DTC P0174 indicates adaptive fuel control air/fuel ratio is too lean (left bank).

Possible Causes

Fuel control system uses fuel trim tables stored in PCM to compensate for variances in fuel system components from wear and aging. The fuel trim strategy learns deviations during closed-loop engine operation. Fuel trim has 2 means of adapting; a long term fuel trim and a short term fuel trim. Inputs from ECT, IAT and MAF sensors are required to activate fuel trim adjustments. The HO2S detects presence of oxygen in exhaust and provides PCM with feedback identifying air/fuel ratio. A fuel trim factor is added to fuel injector pulse width calculation according to long and short term fuel trims. Long term fuel trim values at their rich or lean limits indicate a fuel system malfunction. Possible causes are:

Low fuel pressure or running out of fuel.

Excessive fuel pressure.

Leaking fuel injector(s).

Leaking fuel pressure regulator.

Vapor recovery system.

Contaminated fuel injector(s).

Air leaks after MAF sensor.

Vacuum leaks.

Restricted air intake.

PCV system.

Improperly seated engine oil dipstick.

Leaking EGR gasket.

Stuck EGR valve.

Leaking EGR diaphragm or EGR vacuum regulator.

Engine oil overfill.

Engine cam timing.

Cylinder compression.

Exhaust leaks before or near HO2S(s).

Diagnostic Procedures

1. For DTCs P0171 or P0174, go to next step.

2. Read Freeze Frame Data. If DTC P0171 or P0174 data is stored in Freeze Frame Data, go to next step. If data from any other DTC is stored in Freeze Frame Data (meaning a more recent DTC is stored), repair other stored DTC(s) first.

3. Verify Current Input Signal Status With KOER, access ECT V, MAF V, TP V and VSS PIDs. Observe signals. If signals are within specification during KOER, go to next step. If any signal is far out of specification during KOER, inspect suspect sensor and check for excessive resistance in related wiring harness. Repair or replace as necessary. Go to step 14 .

4. Verify Current Input Signal Status Under Trouble Condition Access ECT V, MAF V, TP V and VSS PIDs while simulating Freeze Frame Data conditions. Observe signals. If all signals are okay, go to next step. If any signal has drastic changes, inspect suspect sensor and related wiring harness. Repair or replace as necessary. Go to step 14 .

5. Verify Current Input Signal Status Of Front HO2S For DTC P0171, access O2S11 PID. For DTC P0174, access O2S21 PID. For either DTC, check PID under the following accelerator pedal conditions in Park:

Depress accelerator suddenly (rich condition). Voltage should be more than 0.45 volts.

Release accelerator suddenly (lean condition). Voltage should be less than 0.45 volts.

If voltage is okay, inspect air intake system for leaks. Check from air cleaner to throttle body, from throttle body to dynamic chamber, from dynamic chamber to intake manifold, and vacuum hoses. Repair as necessary. Go to step 14 . If no leaks are present, inspect exhaust system for leaks. Repair as necessary. If no exhaust leaks are present, replace faulty HO2S. Go to step 14 .

6. Inspect MAF V PID With KOER, access MAF V PID. Observe voltage. Verify voltage changes quickly with engine RPM. If voltage is okay, go to next step. If voltage is not okay, replace faulty MAF sensor. Go to step 14 .

7. Inspect For Excessive Air Suction Of Intake Air System Visually inspect air intake system for damage or loose parts. If a problem is found, repair or replace as necessary. Go to step 14 . If no problem is found, go to next step.

8. Inspect Fuel Line Pressure Turn ignition off. Connect a fuel pressure gauge to vehicle. With KOER fuel pressure should be 30-65 psi (207-448 kPa). If fuel pressure is within specification, go to step 12 . If fuel pressure is not within specification, go to next step.

9. Inspect Fuel Pump Circuit Turn ignition off. Inspect fuel pump circuit for open or poor connection. If circuit is okay, go to next step. If circuit is not okay, repair or replace as necessary. Go to step 14 .

10. Inspect Fuel Line From Fuel Pump To Fuel Delivery Line Visually inspect fuel lines for damage or leakage. If fuel lines are okay, repair or replace as necessary. Go to step 14 . If fuel lines are okay, go to next step.

NOTE: Low pressure side fuel filter is located at bottom of fuel pump module inside fuel tank.

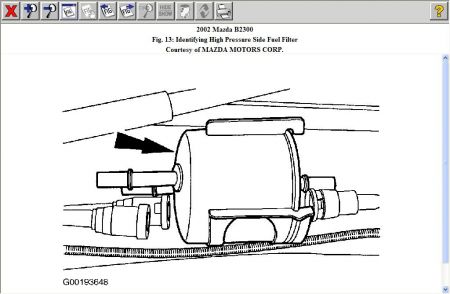

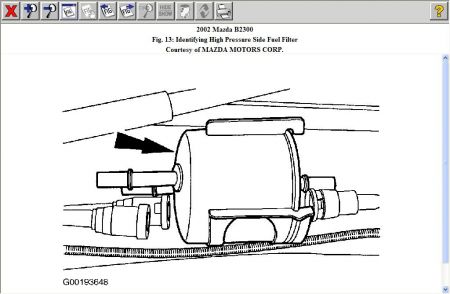

11. Inspect Fuel Filter Inspect fuel filters. If high pressure side fuel filter is plugged, replace faulty fuel filter. See Fig. 13 . After repair, go to step 14 . If low pressure side fuel filter is stained or has foreign material, clean fuel filter and tank. After repair, go to step 14 . If fuel filters are okay, replace fuel pump. After repair, go to step 14 .

12. Inspect Engine Compression Inspect engine compression. If engine compression is okay, go to next step. If engine compression is not okay, repair engine as necessary.

13. Inspect Fuel Injector Operation Remove injector from suspected bank. Swap injector with an injector from other bank. With KOER, check fuel trim. If injector bank which has suspect injector now indicates lean, turn ignition off. Replace faulty fuel injector. Go to next step. If injector bank which has suspect injector does not indicate lean, go to next step.

14. Drive Cycle Reconnect all electrical connectors. Using scan tool, clear DTC memory. Perform HO2S MONITOR REPAIR VERIFICATION DRIVE CYCLE or FUEL OR MISFIRE MONITOR REPAIR VERIFICATION DRIVE CYCLE in MONITOR REPAIR VERIFICATION DRIVE CYCLES under DRIVE CYCLE PROCEDURES. Using scan tool, retrieve DTCs. If same DTC is not present, go to next step. If same DTC is present, replace faulty PCM. Go to next step.

15. Verify Trouble Shooting Of DTCs Completed Make sure all electrical connectors are reconnected. Clear DTCs from PCM memory using scan tool. Perform QUICK TEST under SELF-DIAGNOSTIC SYSTEM. If no DTCs are present, test is complete.

Thursday, January 29th, 2009 AT 7:51 AM