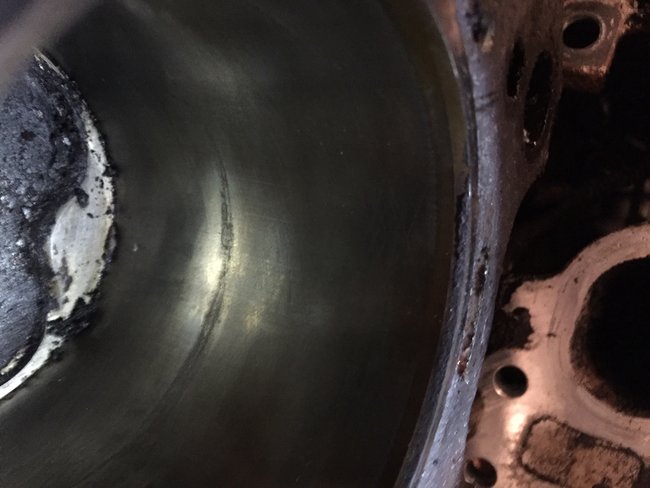

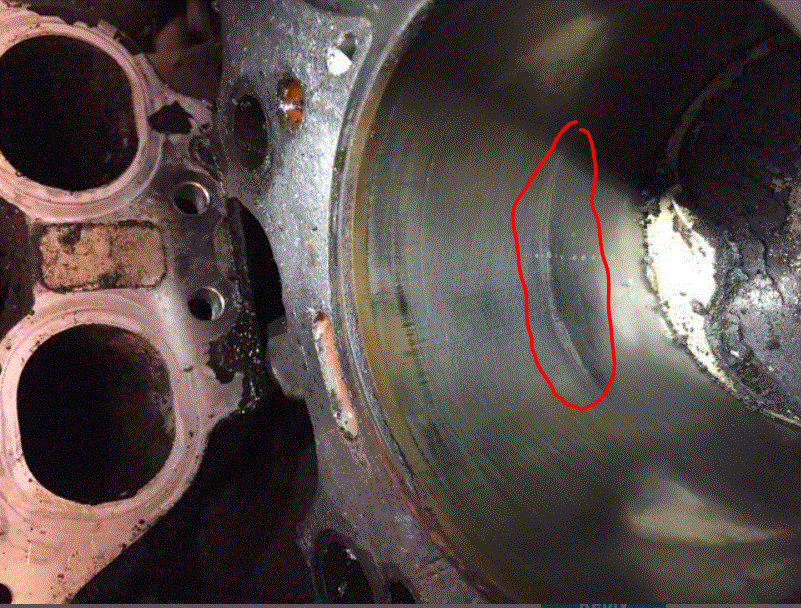

Ugh, that isn't good news. I suspect you are correct. It's interesting that two of them did the same thing nearly at the same place.

I don't know if you plan to replace the engine, but here are the directions if you want them. Be prepared, they are extensive.

______________________

1994 Toyota Camry Sedan 4-Door L4-132 2164cc 2.2L DOHC (5S-FE)

Removal and Installation

Vehicle Engine, Cooling and Exhaust Engine Service and Repair Procedures Removal and Installation

REMOVAL AND INSTALLATION

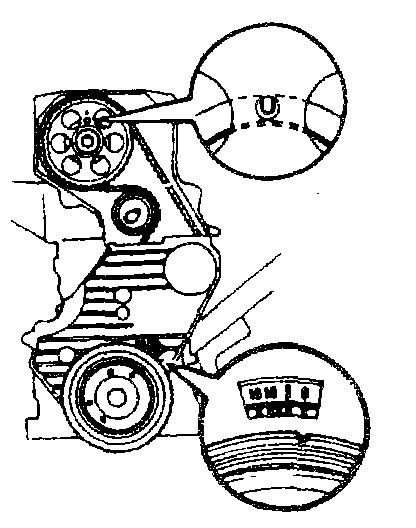

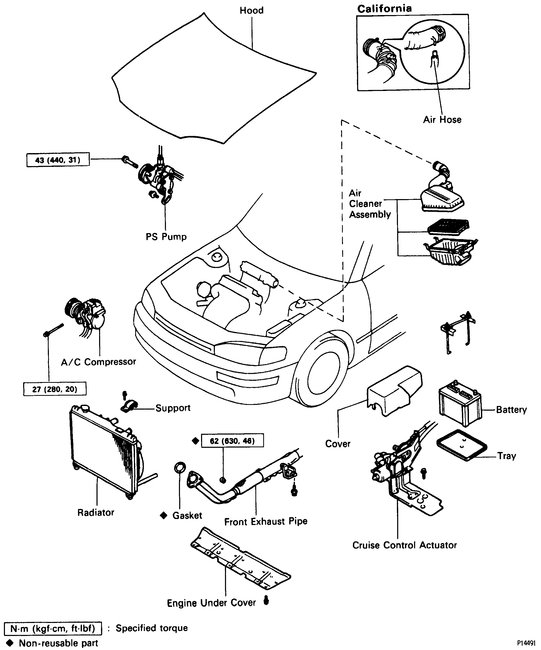

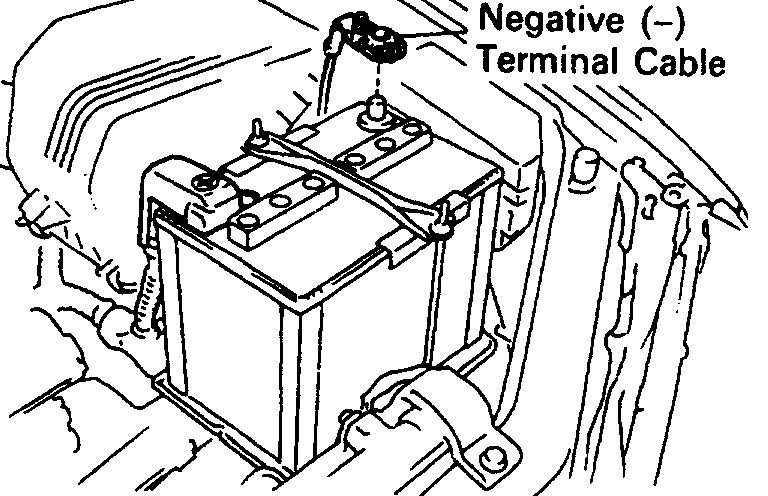

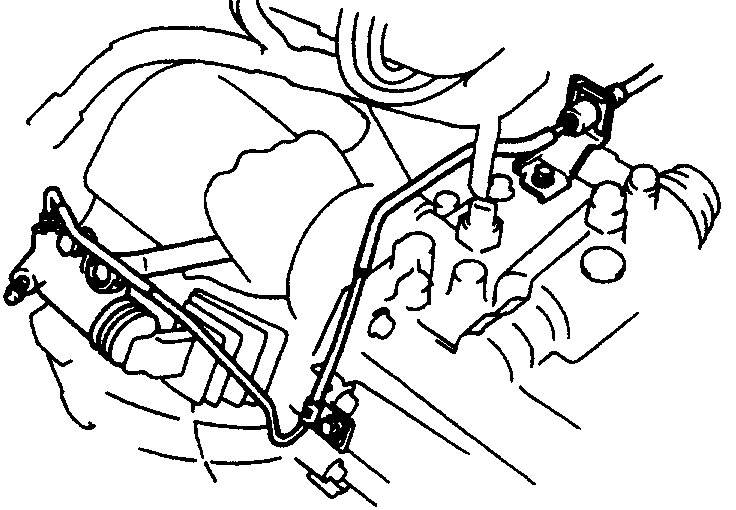

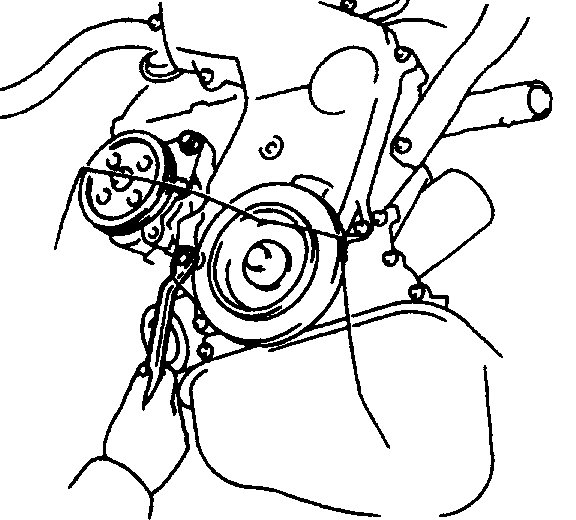

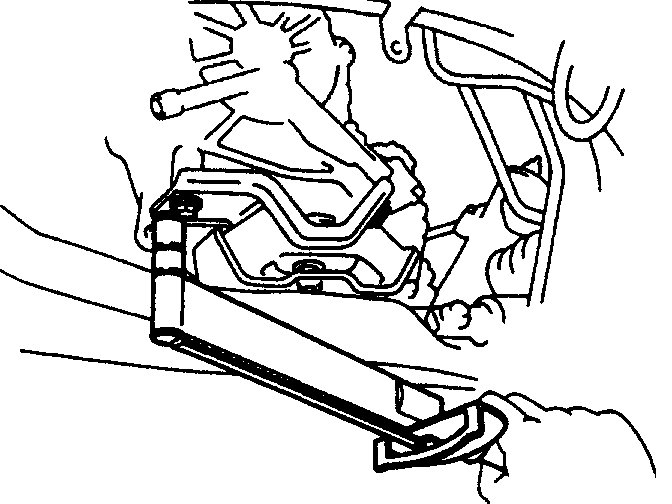

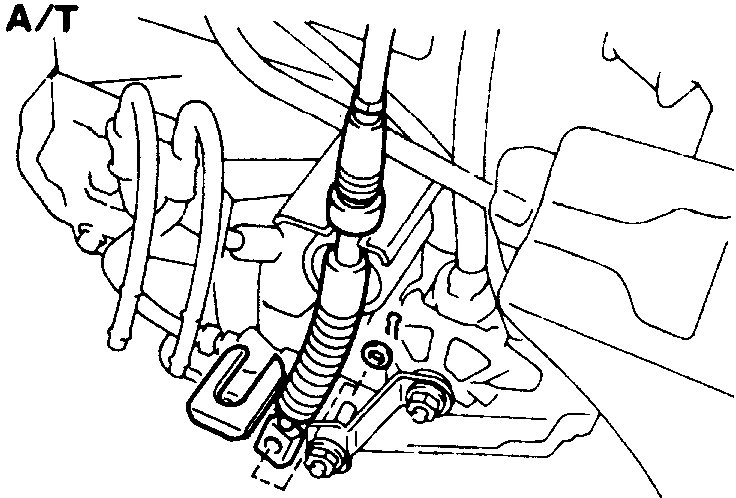

pic 1

pic 2

ENGINE REMOVAL

pic 3

1. DISCONNECT NEGATIVE (-) TERMINAL CABLE FROM BATTERY

CAUTION: Work must be started after 90 seconds from the time the ignition switch is turned to the LOCK position and the negative (-) terminal cable 1s disconnected from the battery.

2. REMOVE BATTERY AND TRAY

3. REMOVE HOOD

4. REMOVE ENGINE UNDER COVER

5. DRAIN ENGINE COOLANT

6. DRAIN ENGINE OIL

7. DISCONNECT ACCELERATOR CABLE FROM THROTTLE BODY

8. A/T: DISCONNECT THROTTLE CABLE FROM THROTTLE BODY

pic 4

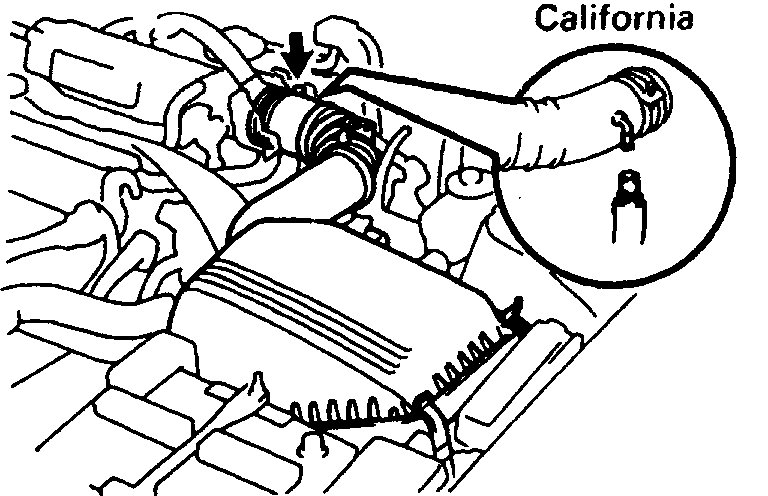

9. REMOVE AIR CLEANER ASSEMBLY, RESONATOR AND AIR CLEANER HOSE

(a) Disconnect the intake air temperature sensor connector.

(b) California only: Disconnect the air hose from the air cleaner hose.

(c) Loosen the air cleaner hose clamp bolt.

(d) Disconnect the 4 air cleaner cap clips.

(e) Disconnect the air cleaner hose from the throttle body. And remove the air cleaner cap together with the resonator and air cleaner hose.

(f) Remove the element.

(g) Remove the 3 bolts and air cleaner case.

Pic 5

10. W/ CRUISE CONTROL SYSTEM: REMOVE CRUISE CONTROL ACTUATOR

(a) Remove the actuator cover.

(b) Disconnect the actuator connector.

(c) Remove the 3 bolts, and disconnect the actuator with the bracket.

11. REMOVE RADIATOR

12. DISCONNECT WIRES AND CONNECTORS

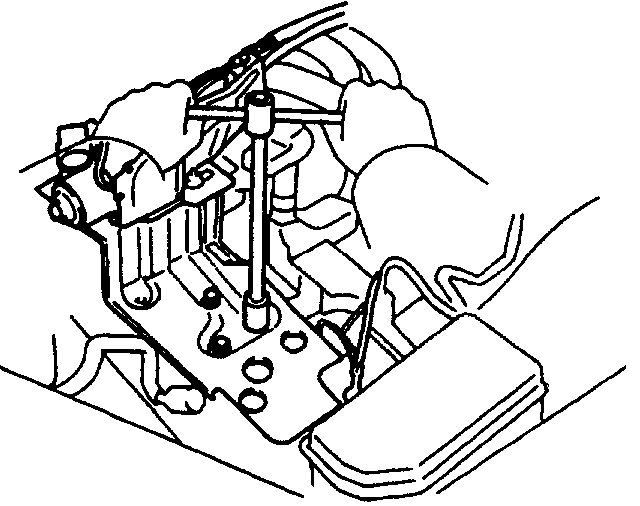

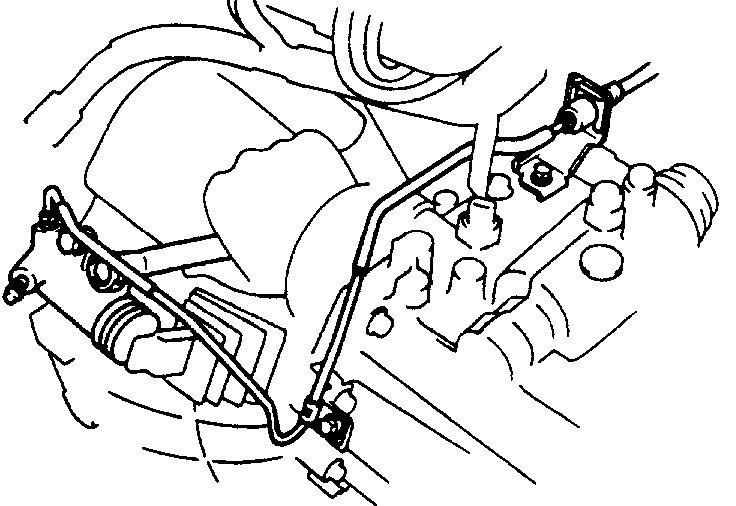

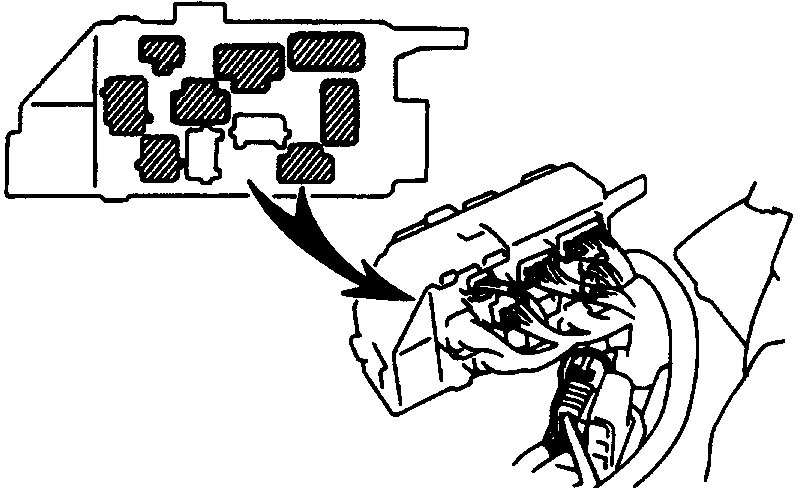

pic 6

(a) Remove the engine relay box. And disconnect the 5 connectors.

(b) Connector from LH fender apron

(c) Disconnect the following connectors:

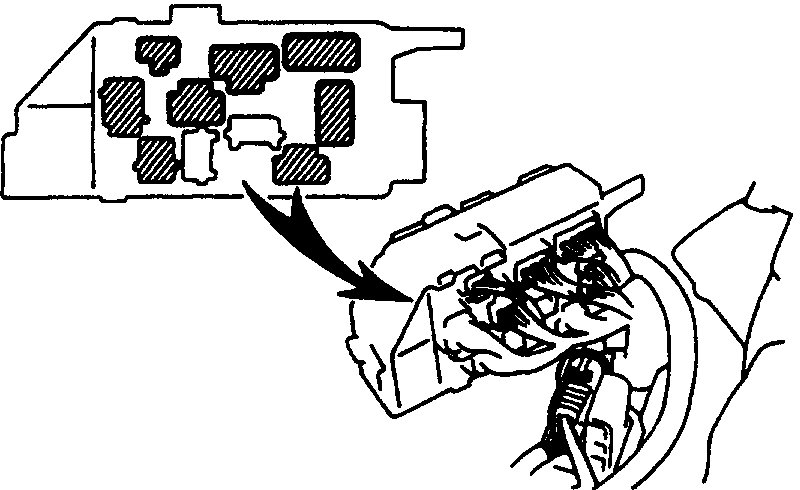

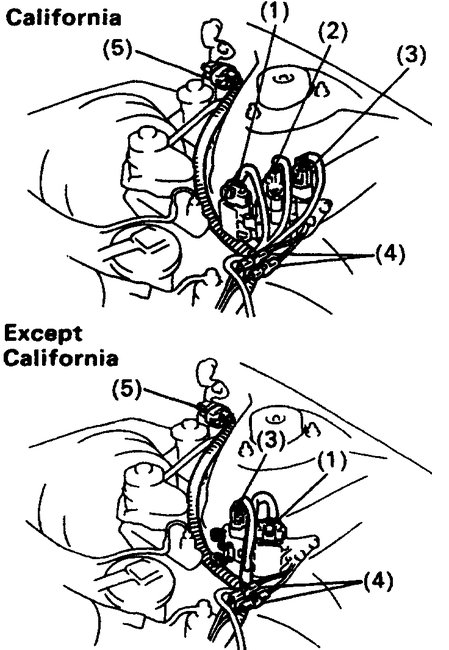

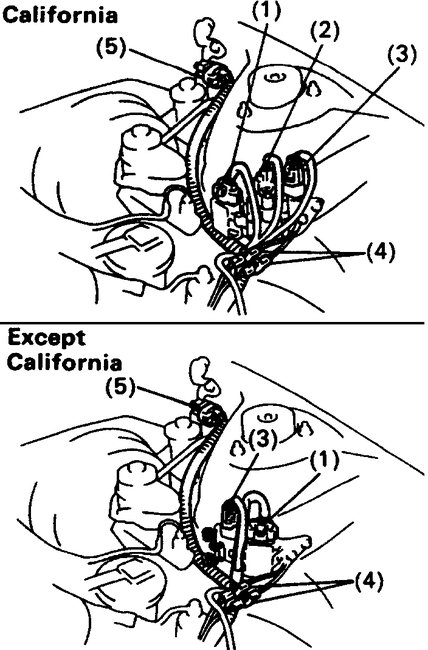

pic 7

(1) Igniter connector

(2) California only: Ignition coil connector

(3) Noise filter connector

(4) 2 ground straps from LH fender apron

(5) Connector from LH fender apron

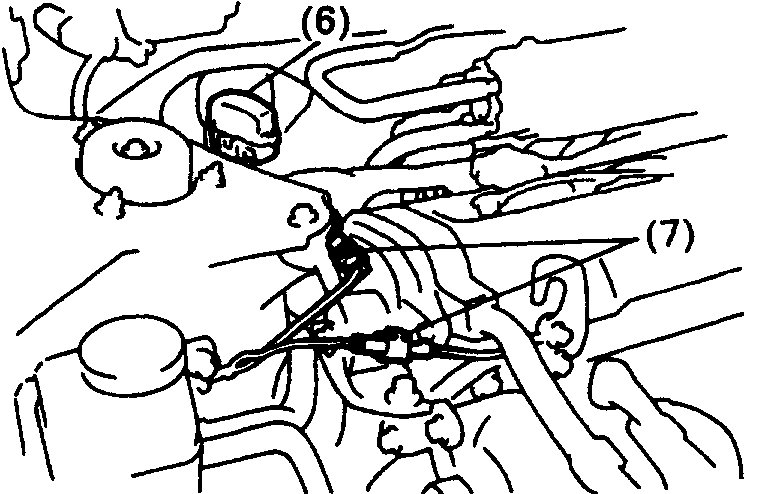

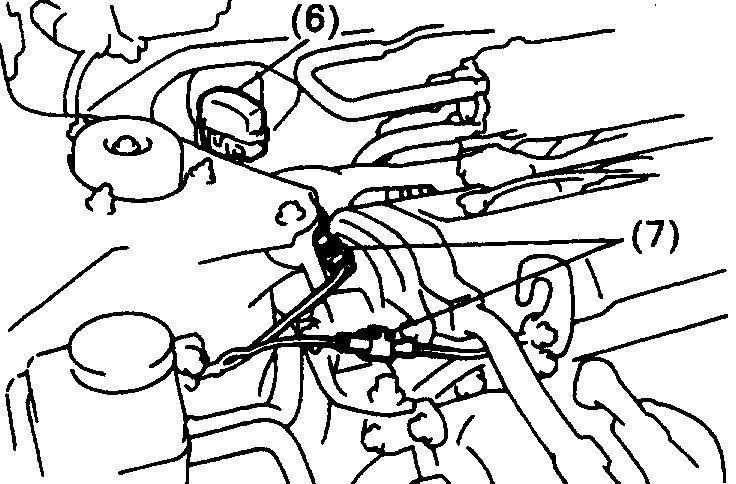

pic 8

(6) Data link connector 1

(7) 2 ground straps from RH fender apron

(d) Disconnect the MAP sensor connector.

Pic 9

13. DISCONNECT HEATER HOSES

14. DISCONNECT FUEL RETURN HOSE

CAUTION: Catch leaking fuel in a container.

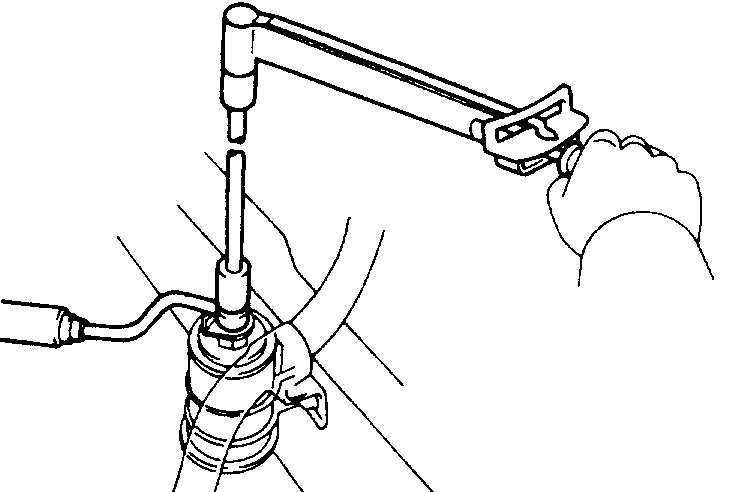

Pic 10

15. DISCONNECT FUEL INLET HOSE

CAUTION: Catch leaking fuel in a container.

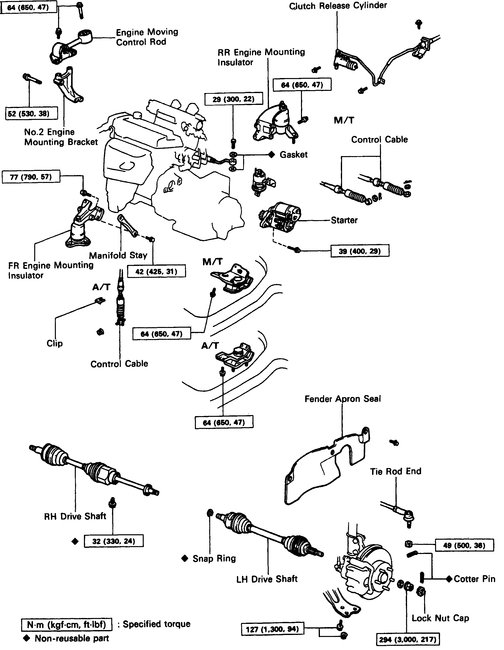

16. M/T: REMOVE STARTER

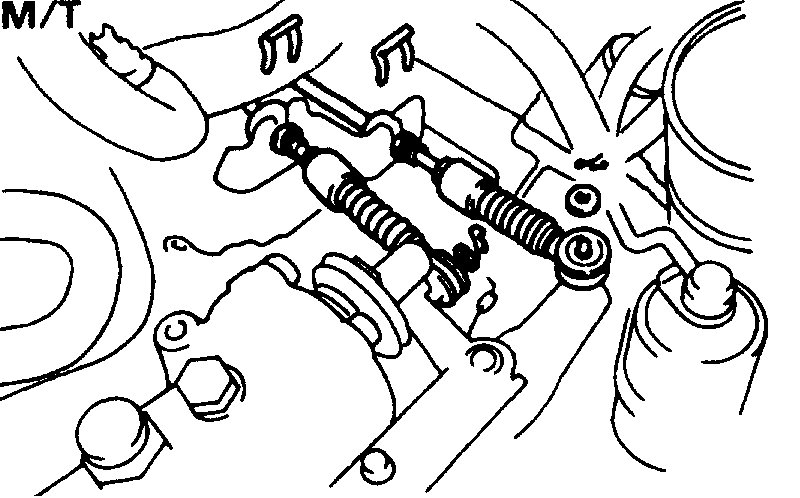

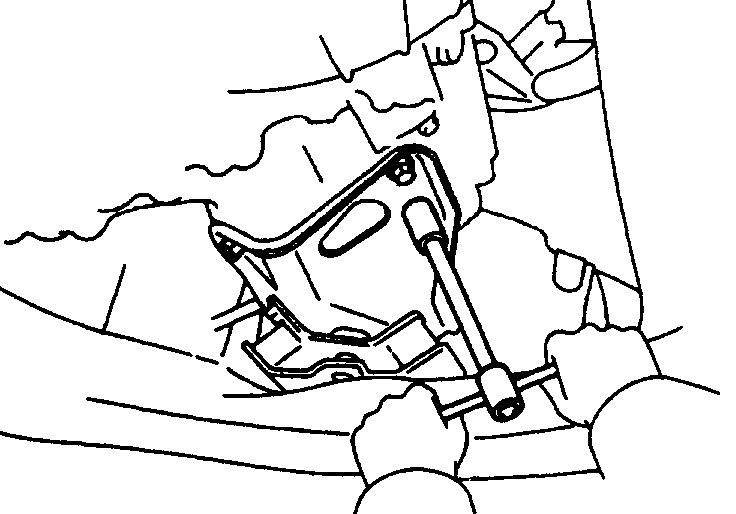

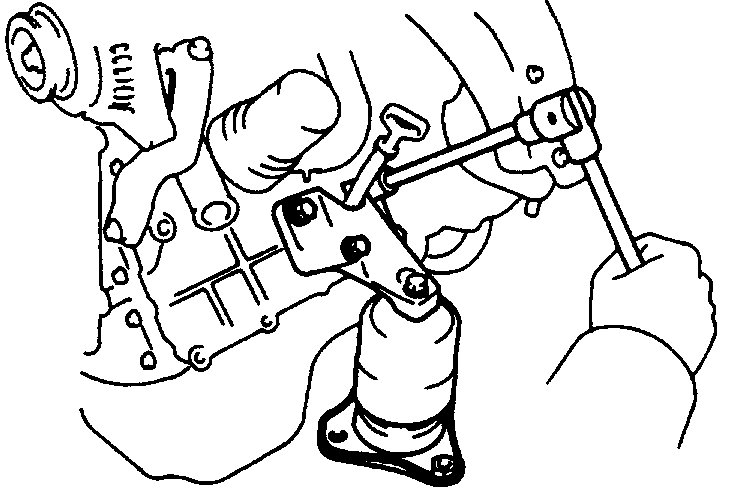

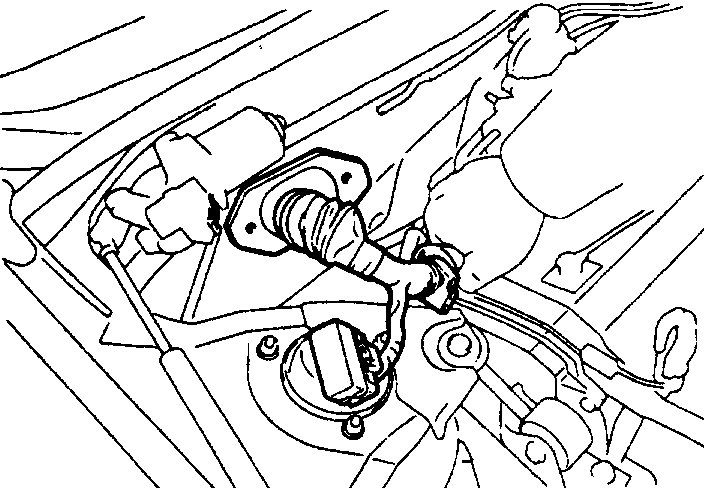

pic 11

17. M/T: REMOVE CLUTCH RELEASE CYLINDER WITHOUT DISCONNECTING TUBE

- Remove the 4 bolts, release cylinder and tube from the transaxle.

Pic 12

pic 13

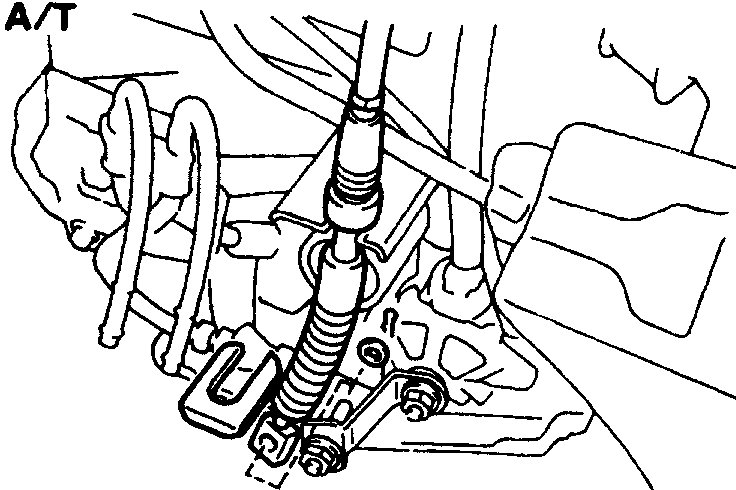

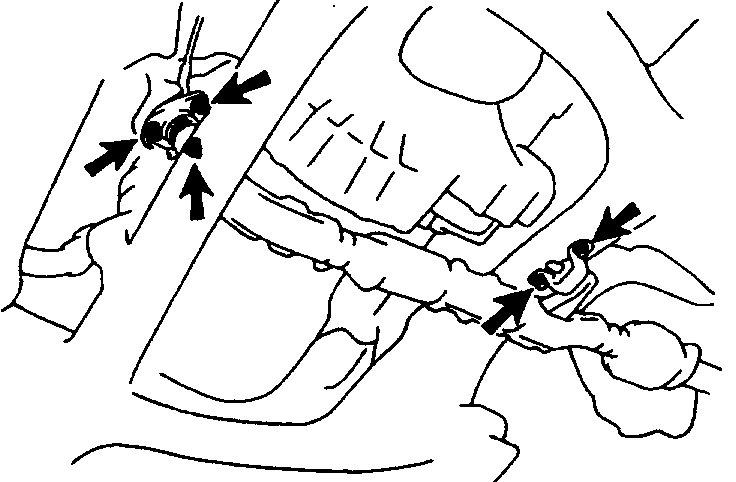

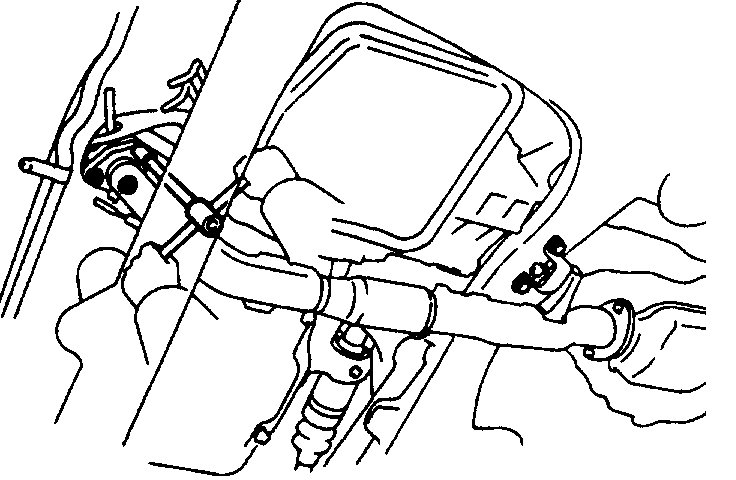

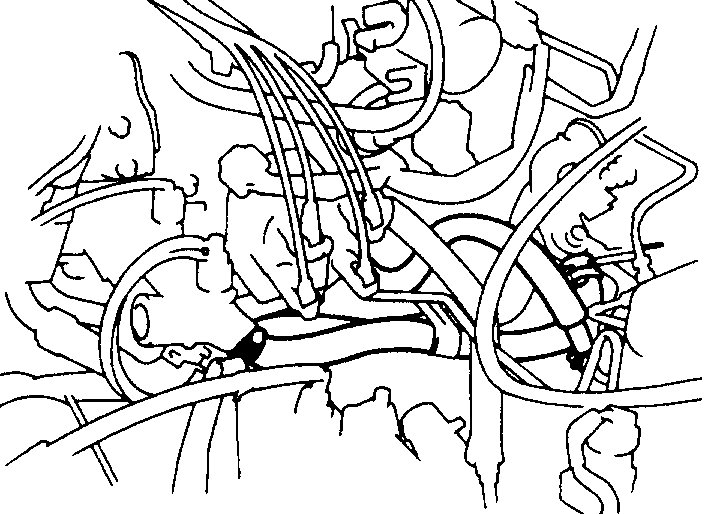

18. DISCONNECT TRANSAXLE CONTROL CABLE(S) FROM TRANSAXLE

19. DISCONNECT VACUUM HOSES

pic 14

(a) MAP sensor hose from air intake chamber

(b) Brake booster vacuum hose from air intake chamber

(c) Charcoal canister vacuum hose

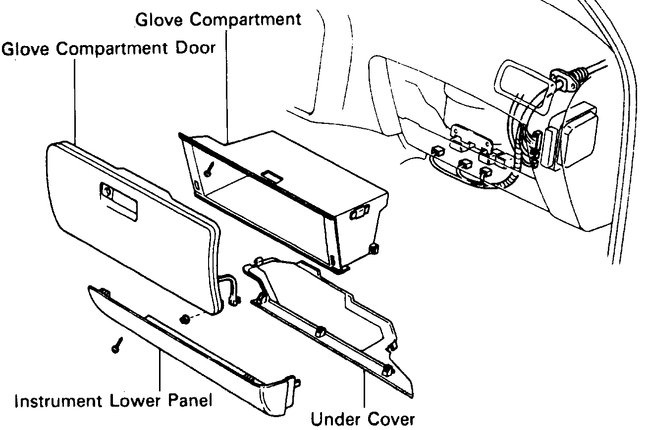

20. DISCONNECT ENGINE WIRE FROM CABIN

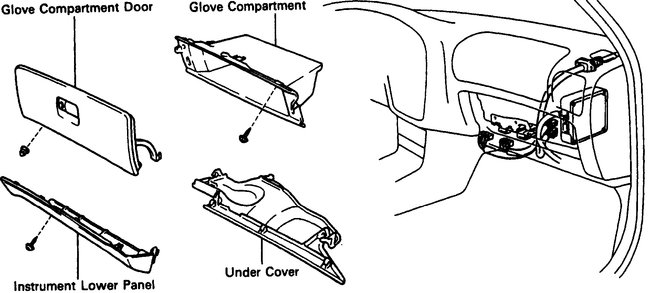

pic 15

(a) Remove the under cover.

(b) Remove the lower instrument panel.

(c) Remove the glove compartment door.

(d) Remove the glove compartment.

(e) Disconnect the following connectors:

(1) 2 ECM connectors

(2) 2 cowl wire connector

pic 16

(f) Remove the 2 nuts, and pull out the engine wire from the cowl panel.

Pic 17

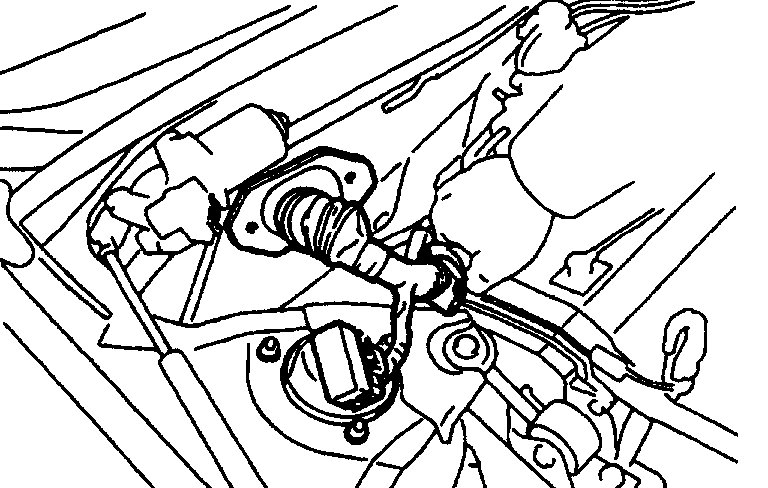

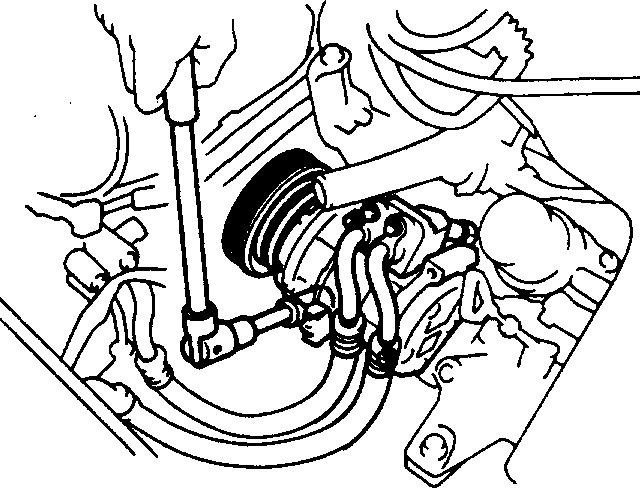

21. W/ A/C: REMOVE A/C COMPRESSOR WITHOUT DISCONNECTING HOSES

(a) Disconnect the A/C compressor connector.

(b) Remove the drive belt.

(c) Remove the 3 bolts, and disconnect the A/C compressor.

HINT: Put aside the compressor, and suspend it from the radiator support.

Pic 18

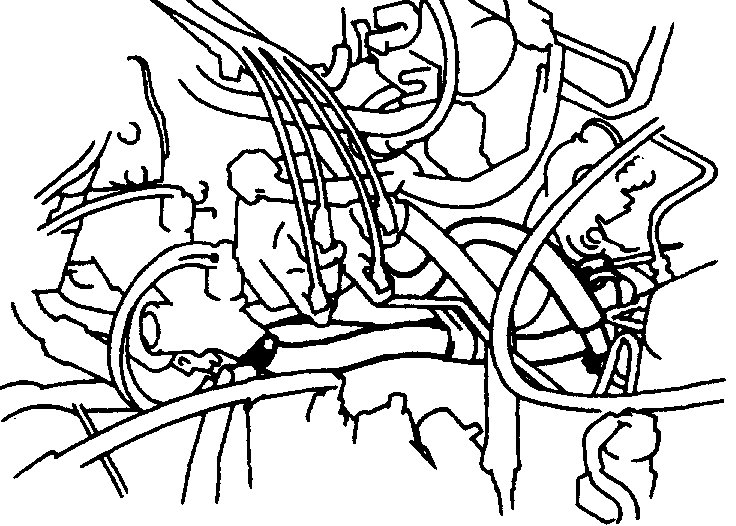

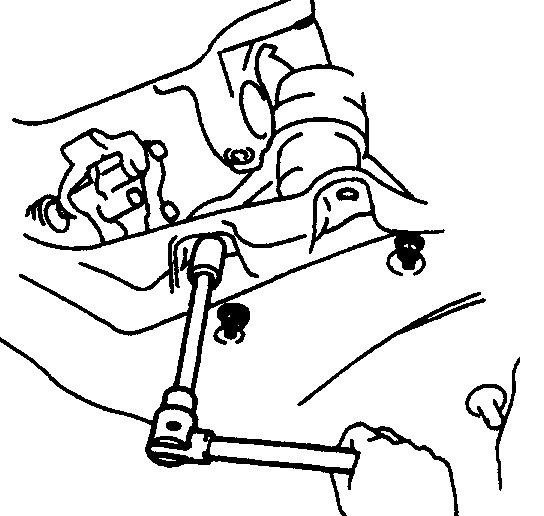

22. DISCONNECT FRONT EXHAUST PIPE

(a) Loosen the 2 bolts, and disconnect the bracket.

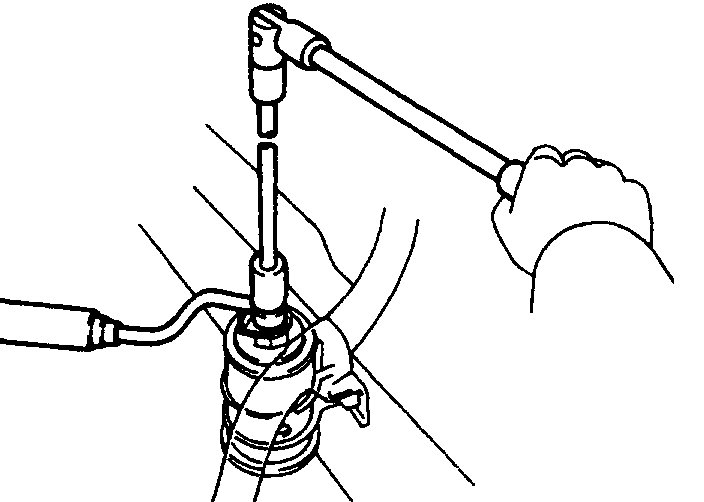

(b) Using a 14 mm deep socket wrench, remove the 3 nuts holding the front exhaust pipe to the WU-TWC.

(c) Disconnect the front exhaust pipe and gaskets.

23. REMOVE DRIVE SHAFTS

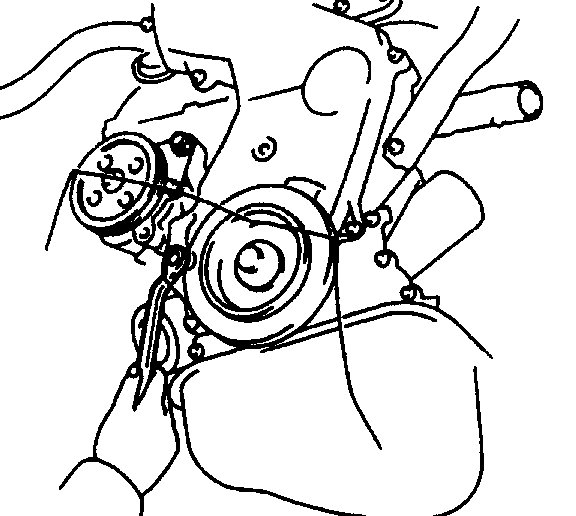

pic 19

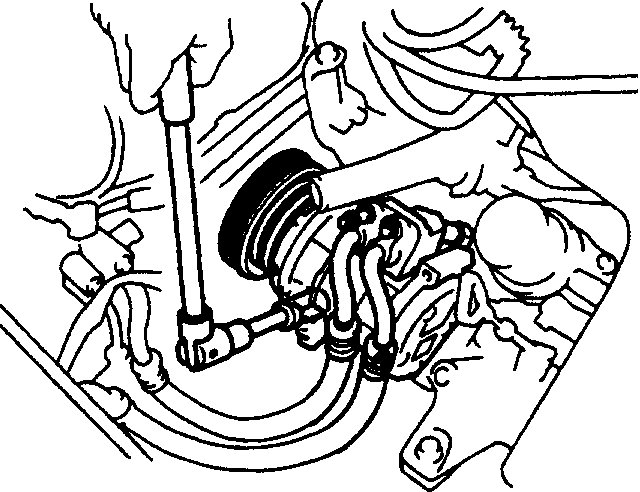

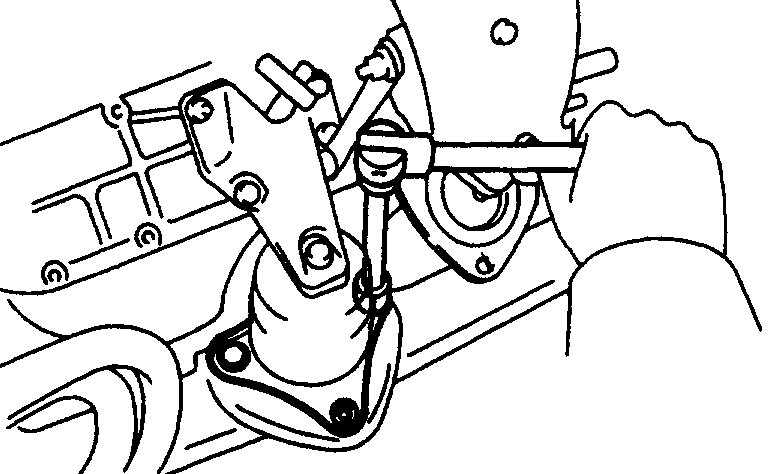

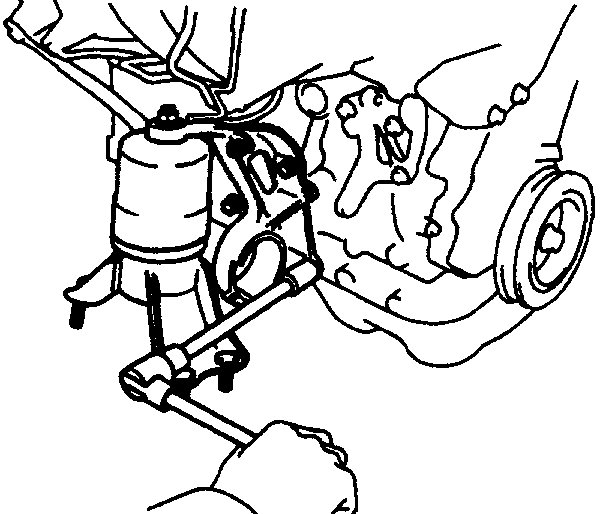

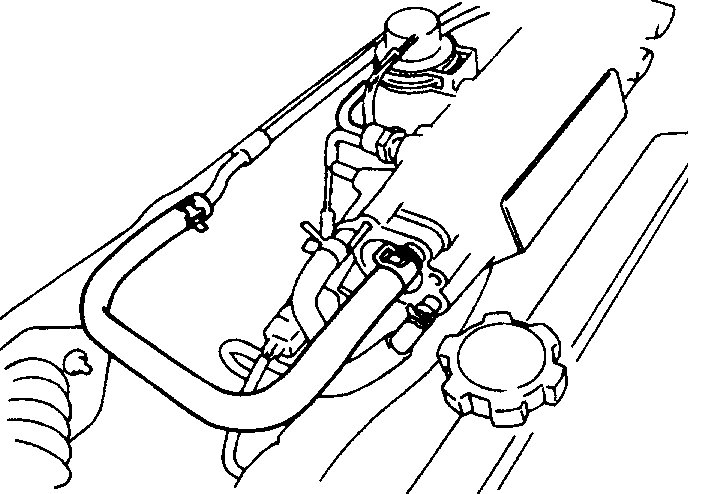

24. REMOVE PS PUMP WITHOUT DISCONNECTING HOSES

(a) Disconnect the 2 air hoses from the air pipe.

(b) Remove the PS drive belt.

(c) Remove the 2 bolts, and disconnect the PS pump from the engine.

HINT: Put aside the pump and suspend it from the cowl with a string.

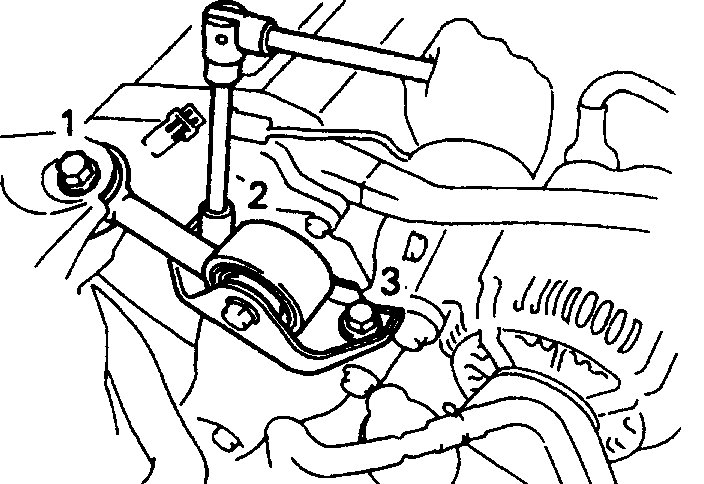

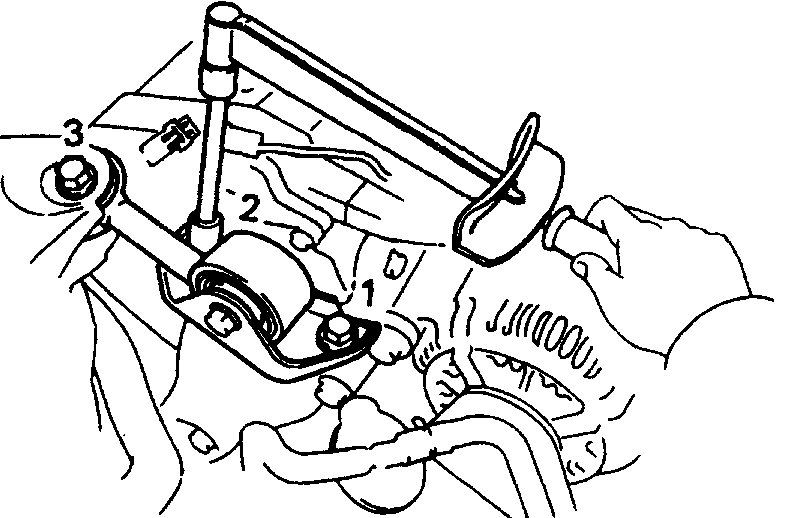

25. DISCONNECT LH ENGINE MOUNTING INSULATOR

pic 20

M/T: Remove the 3 bolts, and disconnect the mounting insulator.

Pic 21

A/T: Remove the 4 bolts, and disconnect the mounting insulator.

Pic 22

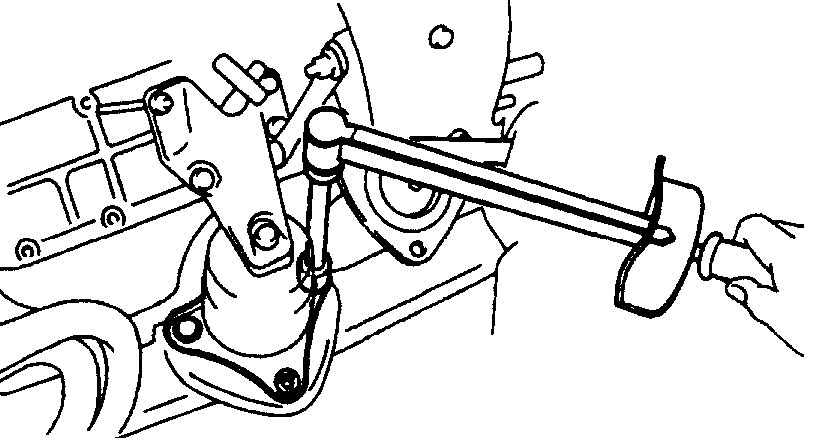

26. DISCONNECT RR ENGINE MOUNTING INSULATOR

(a) Remove the hole plugs.

(b) Remove the 3 nuts, and disconnect the mounting insulator.

Pic 23

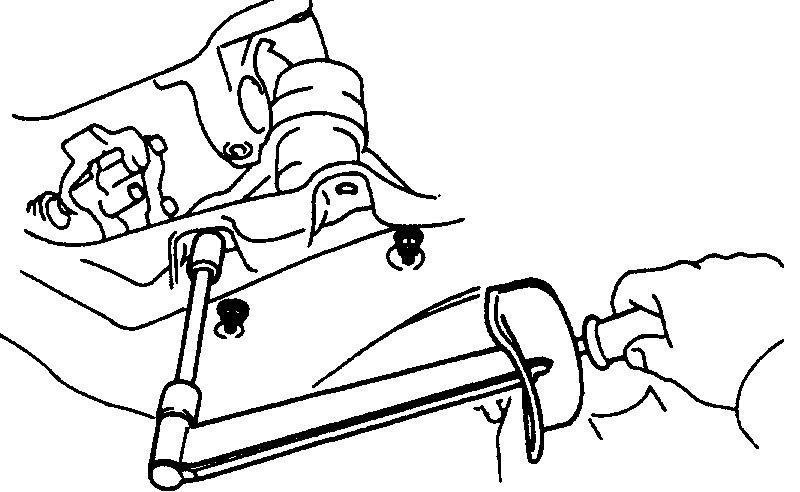

27. DISCONNECT FR ENGINE MOUNTING INSULATOR

- Remove the 3 bolts, and disconnect the mounting insulator.

Pic 24

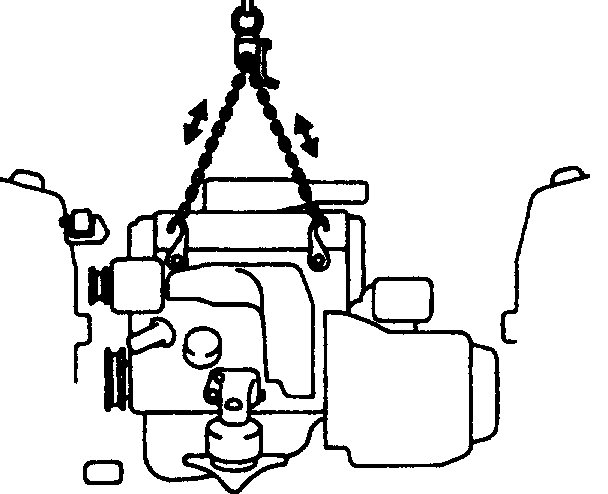

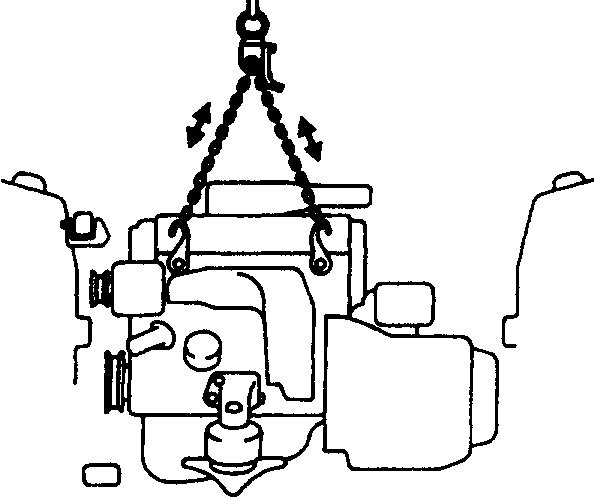

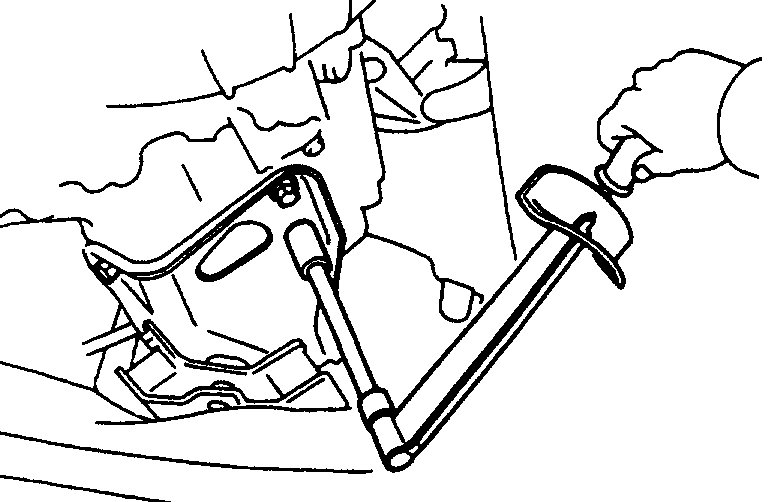

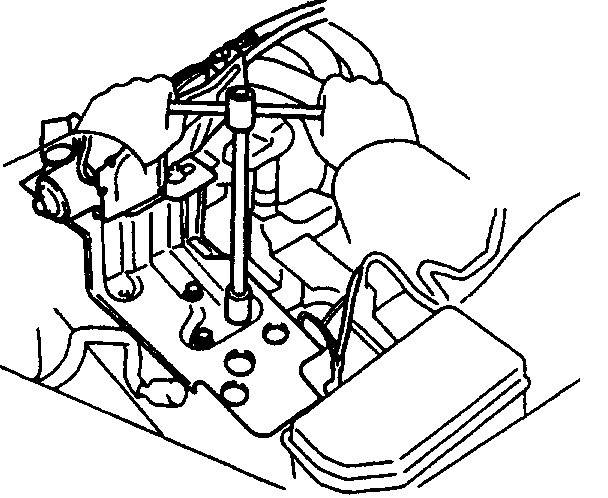

28. ATTACH ENGINE SLING DEVICE TO ENGINE HANGERS

pic 25

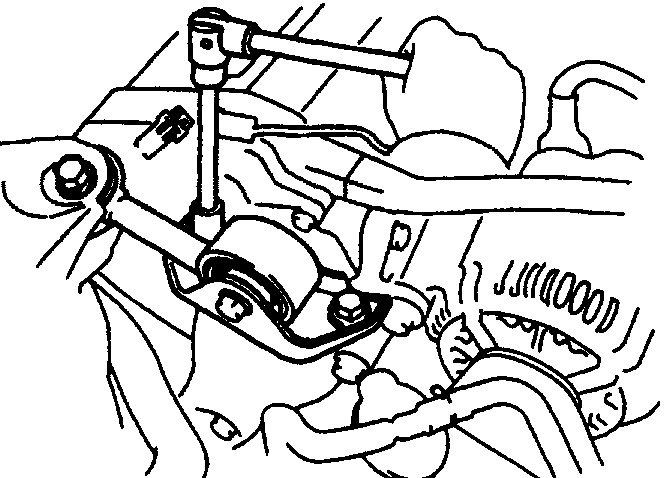

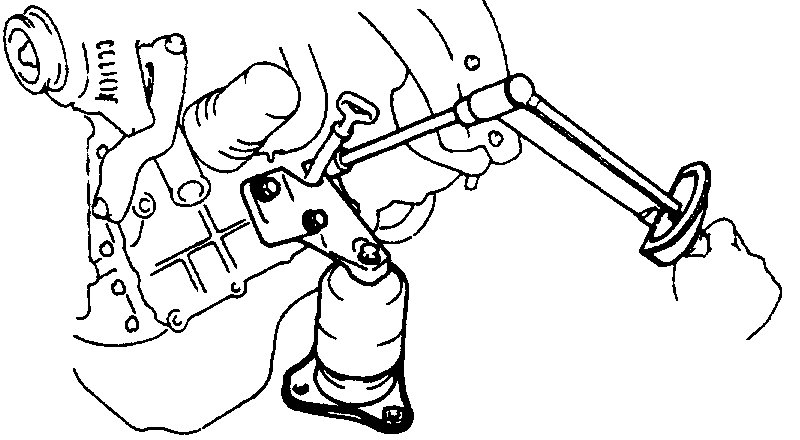

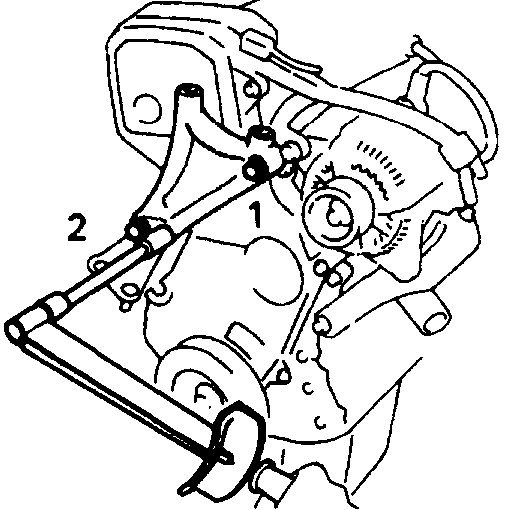

29. REMOVE ENGINE MOVING CONTROL ROD

- Remove the 3 bolts and control rod.

Pic 26

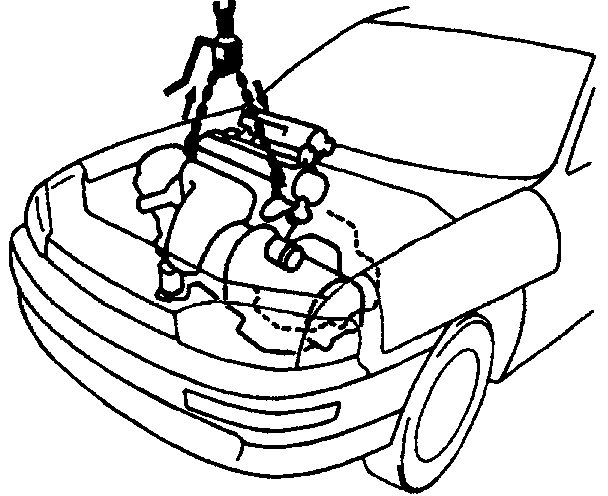

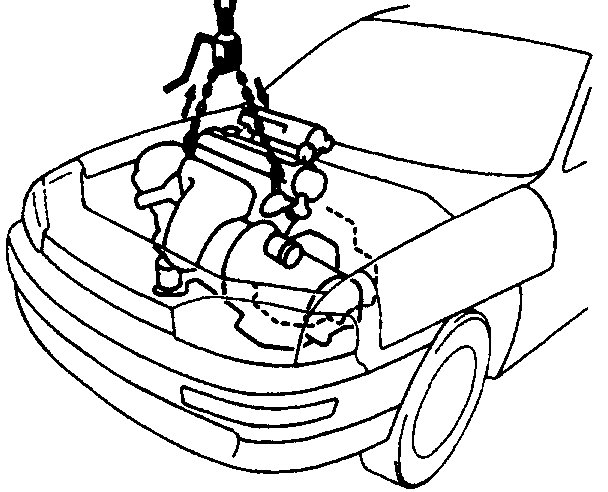

30. REMOVE ENGINE AND TRANSAXLE ASSEMBLY FROM VEHICLE

(a) Lift the engine out of the vehicle slowly and carefully.

NOTICE: Be careful not to hit the PS gear housing or park/neutral position switch (A/T).

(b) Make sure the engine is clear of all wiring, hoses and cables.

(c) Place the engine and transaxle assembly onto the stand.

31. A/T: REMOVE STARTER

32. SEPARATE ENGINE AND TRANSAXLE

pic 27

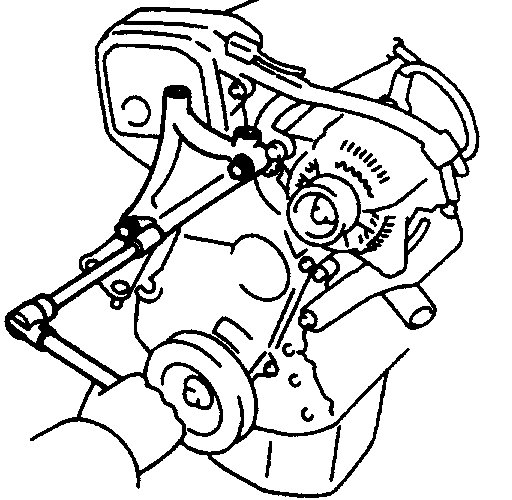

33. REMOVE NO.2 RH ENGINE MOUNTING BRACKET

- Remove the 3 bolts and engine mounting bracket.

Pic 28

34. REMOVE FR ENGINE MOUNTING INSULATOR

(a) Remove the bolt, nut and manifold stay.

(b) Remove the 4 bolts and mounting insulator.

Pic 29

35. REMOVE RR ENGINE MOUNTING INSULATOR

- Remove the 4 bolts and mounting insulator.

ENGINE INSTALLATION

pic 30

1. INSTALL RR ENGINE MOUNTING INSULATOR

- Install the mounting insulator with the 4 bolts.

Torque: 64 N.M (650 kgf. Cm, 47 ft. Lbf)

pic 31

2. INSTALL FR ENGINE MOUNTING INSULATOR

(a) Install the mounting insulator with the 4 bolts.

Torque: 77 N.M (790 kgf. Cm, 57 ft. Lbf)

(b) Install the manifold stay with the bolt and nut.

Torque: 42 N.M (425 kgf. Cm. 31 ft. Lbf)

3. INSTALL NO.2 ENGINE MOUNTING BRACKET

pic 32

(a) Temporarily install the No.2 engine mounting bracket with the 2 bolts.

Pic 33

(b) Install the remaining bolt.

(c) Tighten the 3 bolts in the sequence shown.

Torque: 52 N.M (530 kgf. Cm, 38 ft. Lbf)

4. ASSEMBLE ENGINE AND TRANSAXLE

5. A/T: INSTALL STARTER

pic 34

6. INSTALL ENGINE AND TRANSAXLE ASSEMBLY IN VEHICLE

(a) Attach the engine sling device to the engine hangers.

(b) Lower the engine into the engine compartment. Tilt the transaxle downward, lower the engine and clear the LH mounting.

NOTICE: Be careful not to hit the PS gear housing or park/neutral position switch (A/T).

Pic 35

(c) Keep the engine level, and align RH and LH mountings with the body bracket.

7. INSTALL ENGINE MOVING CONTROL ROD

pic 36

(a) Temporarily install the engine moving control rod with the 3 bolts in the sequence shown.

Image

(b) Tighten the 3 bolts in the sequence shown.

Torque: 64 N.M (650 kgf. Cm, 47 ft. Lbf)

pic 37

8. CONNECT FR ENGINE MOUNTING INSULATOR

- Connect the mounting insulator with the 3 bolts.

Torque: 80 N.M (820 kgf. Cm, 59 ft. Lbf)

pic 38

9. CONNECT RR ENGINE MOUNTING INSULATOR

(a) Connect the mounting insulator with the 3 nuts.

Torque: 66 N.M (670 kgl. Cm, 48 ft. Lbf)

(b) Install the hole plugs.

10. CONNECT LH ENGINE MOUNTING INSULATOR

pic 39

M/T: Connect the mounting insulator with the 3 bolts.

Torque: 64 N.M (650 kgf. Cm, 47 ft. Lbf)

pic 40

A/T: Connect the mounting insulator with the 4 bolts.

Torque: 64 N.M (650 kgf. Cm, 47 ft. Lbf)

11. REMOVE ENGINE SLING DEVICE

pic 41

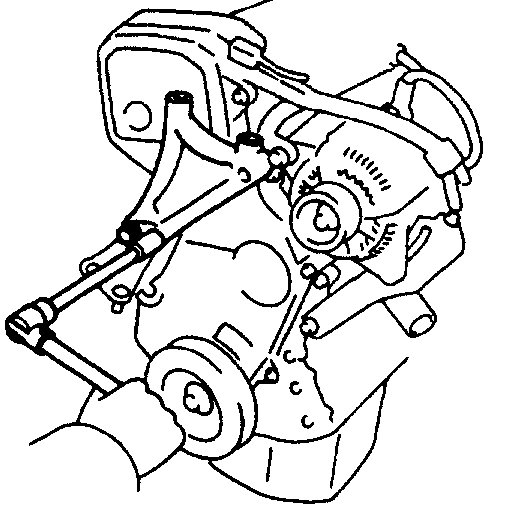

12. INSTALL PS PUMP

(a) Install the PS pump with the 2 bolts.

Torque: 43 N.M (440 kgf. Cm, 31 ft. Lbf)

(b) Install the drive belt.

(c) Connect the 2 air hoses to the air pipe.

13. INSTALL DRIVE SHAFTS

pic 42

14. CONNECT FRONT EXHAUST PIPE

(a) Place a new gasket on the front exhaust pipe.

(b) Using a 14 mm deep socket wrench, install the three new nuts holding the front exhaust pipe to the exhaust manifold (three-way catalytic converter (front).

Torque: 62 N.M (630 kgf. Cm. 46 ft. Lbf)

(c) Install the bracket with the two bolts.

Pic 43

15. (W/ A/C) INSTALL A/C COMPRESSOR

(a) Install the compressor with the three bolts.

Torque: 27 N.M (280 kgf. Cm. 20 ft. Lbf)

(b) Install the drive belt.

(c) Connect the A/C compressor connector.

Pic 44

16. CONNECT ENGINE WIRE TO CABIN

(a) Push in the engine wire through the cowl panel. Install the two nuts.

(b) Connect the following connectors:

pic 45

(1) Two FCM connectors

(2) Four cowl wire connectors

(c) Install the glove compartment.

(d) Install the glove compartment door.

(e) Install the lower instrument panel.

(f) Install the under cover.

Pic 46

17. CONNECT VACUUM HOSES

(a) Vacuum sensor hose to air intake chamber

(b) Brake booster vacuum hose to air intake chamber

(c) Charcoal canister vacuum hose

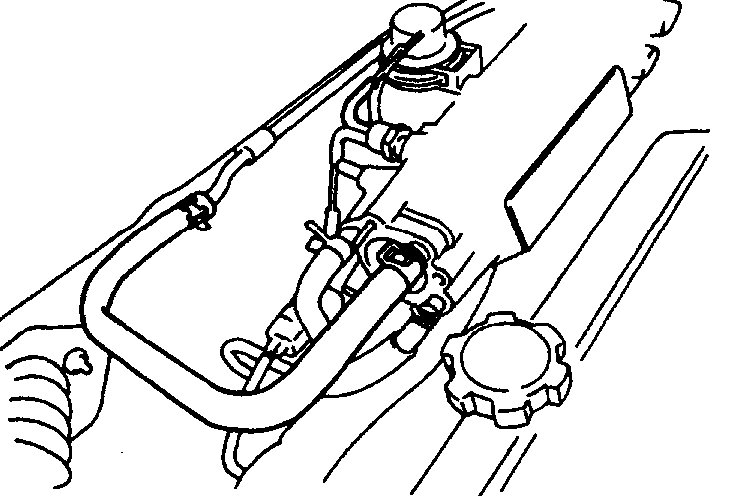

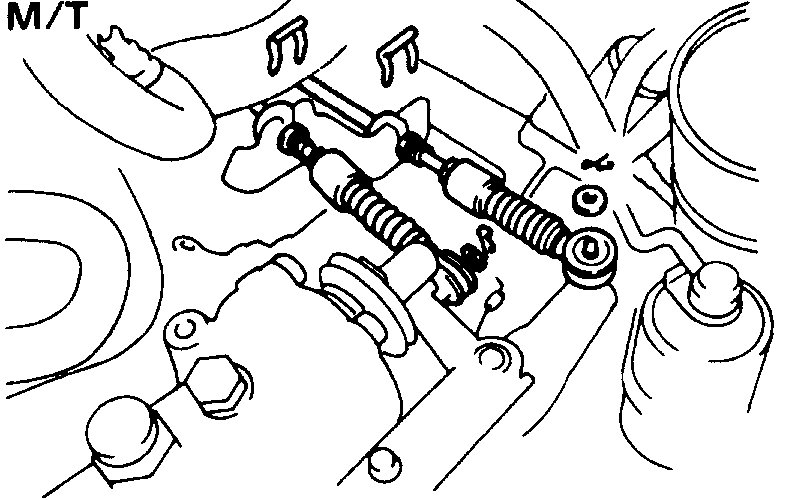

pic 47

pic 48

18. CONNECT TRANSAXLE CONTROL CABLE(S) TO TRANSAXLE

pic 49

19. (M/T) INSTALL CLUTCH RELEASE CYLINDER

- Install the release cylinder and tube with the four bolts.

20. (M/T) INSTALL STARTER

pic 50

21. CONNECT FUEL INLET HOSE

Torque: 29 N.M (300 kgf. Cm, 22 ft. Lbf)

pic 51

22. CONNECT FUEL RETURN HOSE

23. CONNECT HEATER HOSES

24. CONNECT WIRES AND CONNECTORS

pic 52

(a) Connect the 5 connectors to the relay box.

(b) Connectors from LH fender apron.

(c) Install the engine relay box.

(d) Connect the following connectors:

pic 53

(1) Igniter connector

(2) California only: Ignition coil connector

(3) Noise filter connector

(4) 2 ground straps from LH fender apron

(5) Connector from LH fender apron

pic 54

(6) Data link connector 1

(7) 2 ground straps from RH fender apron

(e) Connect the MAP sensor connector.

25. INSTALL RADIATOR

pic 55

26. W/ CRUISE CONTROL SYSTEM: INSTALL CRUISE CONTROL ACTUATOR

(a) Install the actuator and bracket with the 3 bolts.

(b) Connect the actuator connector.

(c) Install the actuator cover.

Pic 56

27. INSTALL AIR CLEANER ASSEMBLY, RESONATOR AND AIR CLEANER HOSE

(a) Install the air cleaner case with 3 bolts.

(b) Install the element.

(c) Connect the air cleaner hose to the throttle body.

(d) Install the air cleaner cap together with the resonator and air cleaner hose.

(e) California only: Connect the air hose to the air cleaner hose.

(f) Connect the intake air temperature sensor connector.

28. A/T: CONNECT AND ADJUST THROTTLE CABLE

29. CONNECT AND ADJUST ACCELERATOR CABLE

30. FILL WITH ENGINE COOLANT

31. FILL WITH ENGINE OIL

Drain and Refill Capacity:

w/ Oil filter change: 3.6 liters (3.8 US qts)

w/o Oil filter change: 3.4 liters (3.6 US qts)

Dry Fill Capacity: 4.2 liters (4.4 US qts)

32. CONNECT NEGATIVE (-) TERMINAL CABLE TO BATTERY

33. START ENGINE AND CHECK FOR LEAKS

34. PREFORM ENGINE ADJUSTMENT

35. INSTALL ENGINE UNDER COVERS

36. INSTALL HOOD

37. PERFORM ROAD TEST

- Check for abnormal noises, shock, slippage, correct shift points and smooth operation.

38. RECHECK ENGINE COOLANT AND ENGINE OIL LEVELS

__________________________

Hope this helps. Let me know your plans.

Take care,

Joe

Images (Click to make bigger)

Monday, February 24th, 2020 AT 8:04 PM