Hi,

First, I would recommend checking fuel pressure to make sure there are no issues.

https://www.2carpros.com/articles/how-to-check-fuel-system-pressure-and-regulator

Also, keep in mind that an engine vacuum leak can cause it to bog down.

https://www.2carpros.com/articles/how-to-use-an-engine-vacuum-gauge

One other thought. Anytime I hear of a power loss like you described, I always check to make sure the catalytic converter is partially plugged. If you hear a rattle or anything when the engine is running, the internal components in the converter could be loose and blocking air flow. Take a rubber mallet and tap on the exhaust to see if any noise is coming from there. Take a look through these two links. The first explains common symptoms of a bad converter and the second explains how to test one. What I do is simply remove an oxygen sensor before the converter to see if there is improvement.

https://www.2carpros.com/articles/bad-catalytic-converter-symptoms

https://www.2carpros.com/articles/how-to-test-a-catalytic-converter

Here are the directions specific to your vehicle for testing fuel pressure. The attached pics correlate with the directions and the manufacturer's specs are included in the directions.

______________________________________

2014 Subaru Forester F4-2.5L DOHC

Component Tests and General Diagnostics

Vehicle Powertrain Management Fuel Delivery and Air Induction Fuel Pump Fuel Pressure Testing and Inspection Component Tests and General Diagnostics

COMPONENT TESTS AND GENERAL DIAGNOSTICS

Fuel Pressure

INSPECTION

CAUTION:

- Be careful not to spill fuel.

- Catch the fuel from the tubes using a container or cloth.

1. Release the fuel pressure.

2. Open the fuel filler lid and remove the fuel filler cap.

3. Disconnect the fuel delivery tube from the fuel delivery pipe, and connect the fuel pressure gauge.

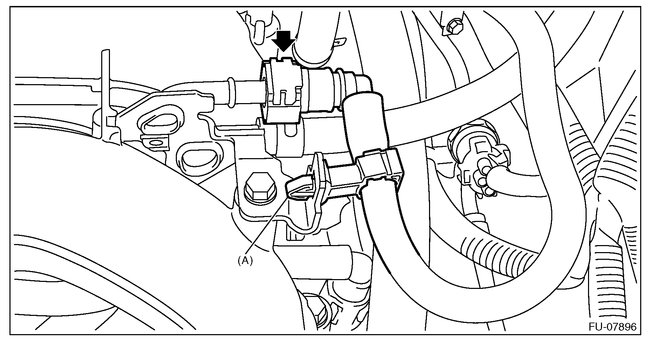

1. Disconnect the quick connector on the fuel delivery tube from the fuel pipe assembly, and remove the clip (A) securing the fuel delivery tube to the fuel pipe assembly.

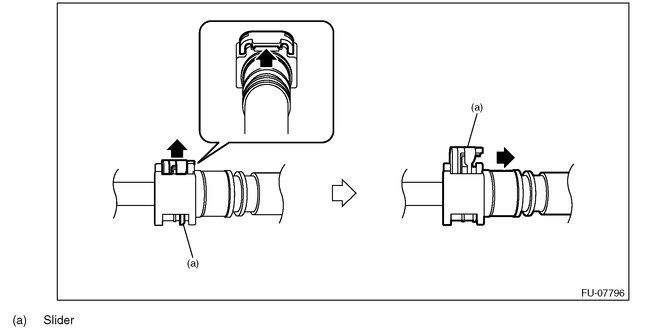

NOTE: Disconnect the quick connector as shown in the figure.

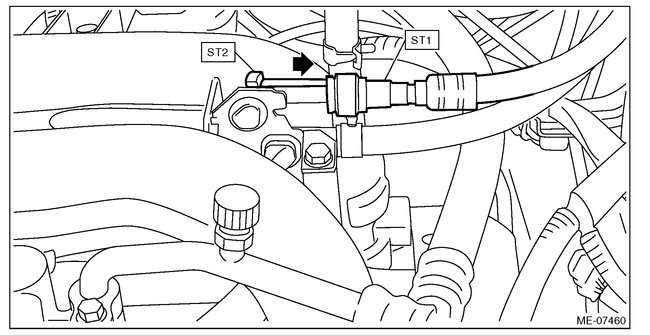

pic 1

pic 2

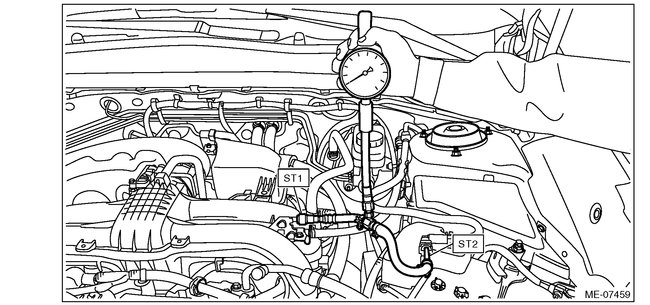

2. Connect the fuel pressure gauge with ST1 and ST2.

CAUTION:

- Check that there is no damage or dust on the quick connector. If necessary, clean the seal surface of the ST2.

- Make sure that the quick connector is securely connected.

NOTE:

- ST1 is a SUBARU genuine part.

- When connecting the ST2 to the quick connector on the fuel delivery tube, connect as shown in the figure.

pic 3

ST1 42075AG690 FUEL HOSE

ST2 18471AA000 FUEL PIPE ADAPTER

pic 4

4. Start the engine.

5. Check the fuel pressure after warming up the engine.

NOTE:

- The fuel pressure gauge registers 10 to 20 kPa (0.1 to 0.2 kgf/cm2, 1 to 3 psi) higher than standard values during high-altitude operations.

- Check or replace the fuel pump and fuel delivery line if the fuel pressure is out of the standard.

Fuel pressure:

Standard: 340 - 400 kPa (3.5 - 4.1 kgf/cm2, 49 - 58 psi)

6. After inspection, install the related parts in the reverse order of removal.

CAUTION:

- Before removing the fuel pressure gauge, release the fuel pressure.

- Be careful not to spill fuel.

- Catch the fuel from hoses and tubes using a container or cloth.

- Check that there is no damage or dust on the quick connector. If necessary, clean the seal surface of the pipe.

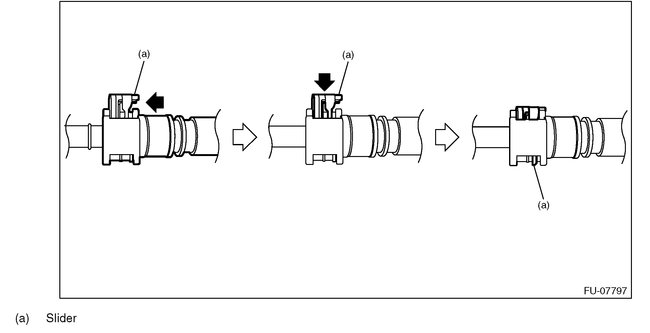

- When connecting the quick connector with slider, make sure to insert the pipe all the way in before locking the slider.

- When it is difficult to lock the slider, check that the pipe is fully inserted.

- Make sure that the quick connector is securely connected.

NOTE:

- When disconnecting the ST1, install the ST2 to the fuel pipe assembly, and press the ST2 in the direction of arrow to disconnect the quick connector on the ST1.

ST1 42075AG690 FUEL HOSE

ST2 42099AE000 QUICK CONNECTOR RELEASE

pic 5

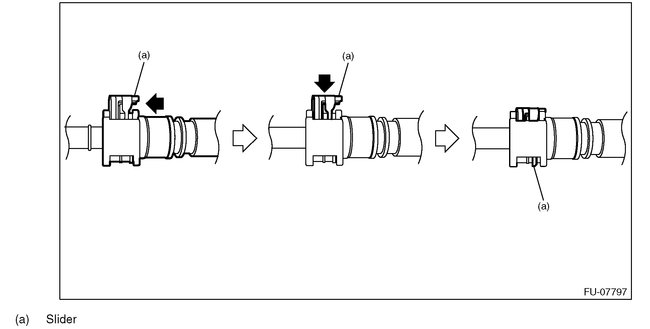

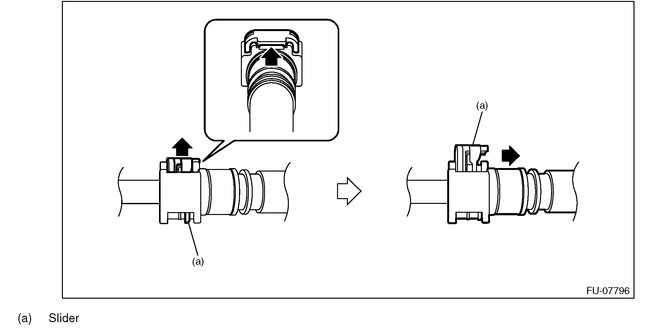

- Disconnect the quick connector on the fuel delivery tube as shown in the figure.

pic 6

- Connect the quick connector on the fuel delivery tube as shown in the figure.

pic 7

____________________________________

If the timing belt hasn't been replaced, you are due to have that done.

Let me know if this helps or if you have other questions.

Take care,

Joe

Images (Click to make bigger)

Thursday, March 5th, 2020 AT 3:59 PM