Hi and thanks for using 2carpros.com

If you are getting too much fuel, then the fuel pressure regulator is most likely the problem and it isn't anything electric. First, check fuel pump pressure to see if the regulator is doing its job. Here is a link that shows in general how it is done. By the way, if you disconnect the vacuum hose going to the pressure regulator and find fuel is in it, replace the regulator.

https://www.2carpros.com/articles/how-to-check-fuel-system-pressure-and-regulator

Here are directions for testing the regulator specific to your vehicle. Fuel pressure specs are included in the directions. Also, the attached pictures correlate with these directions.

_______________________

CHECKING THE FUEL PRESSURE REGULATOR

Checking The Fuel Pressure Regulator

WARNING:

Removal of the fuel pressure regulator is a procedure involving the car's fuel system. It is therefore necessary to observe the following precautions in conjunction with the procedure:

Ensure good ventilation: If there is approved ventilation for extraction of fuel fumes then this must be used.

Wear protective gloves: Prolonged exposure of the hands to fuel can cause irritation of the skin.

Have a fire extinguisher class BE at hand: Be aware of the risk for sparks, i.e. in connection with circuit breaking, short-circuiting, etc.

Absolutely no smoking:

Use protective goggles.

Checks

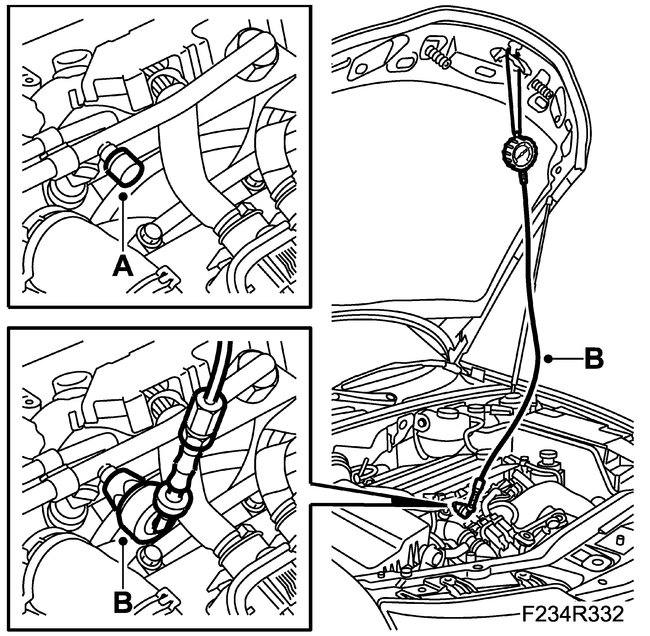

1. Unscrew the valve cap (A). Connect 83 93 852 Pressure measuring equipment, fuel and oil and the adapter (B) 83 94 744 Adapter, fuel pressure gauge. Connect the adapter with "safety on" to the fuel rail. "Safety off" the adapter.

pic 1

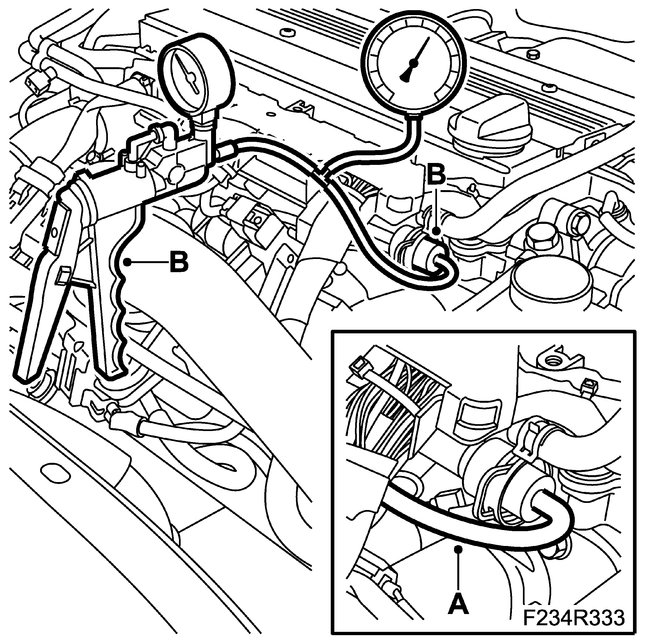

2. Detach the vacuum hose from the pressure regulator (A) and connect pressure/vacuum pump (B), 30 14 883 Pressure/vacuum pump, and charge pressure meter (B), 83 93 514 Charge pressure meter.

pic 2

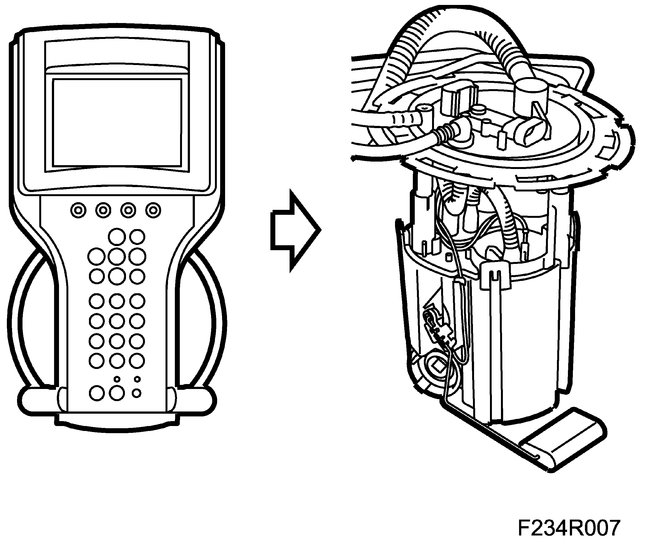

3. Start the fuel pump using the diagnostics tool.

pic 3

4. Check the reading at atmospheric pressure. The reading should be 3 bar (43 psi).

5. Increase the vacuum in the pressure regulator by means of the pressure/vacuum pump. System pressure should drop by the same amount as indicated on the pressure gauge.

System Pressure .................... 3 bar (43 psi)

6. Pump up the pressure in the pressure regulator with the vacuum pump. The system pressure should now increase with the same amount as the reading on the pressure gauge.

7. Switch off the fuel pump using the diagnostics tool.

8. "Safety on" the adapter and remove the pressure measuring equipment from the service nipple. Collect any fuel spill with a rag.

9. Remove the gauges and adapters; reconnect the hose to the fuel pressure regulator.

_____________________________________________

If you determine the regulator is bad, here are the directions for replacing it. The attached pictures correlate with these directions.

FUEL PRESSURE REGULATOR

Fuel Pressure Regulator

WARNING:

Removal of the fuel pressure regulator involves partial dismantling of the car's fuel system. The following points must therefore be observed in connection with this work:

Have a class BE fire extinguisher on hand: Be aware of the risk of sparks, i.e. in connection with electric circuits, short-circuiting, etc.

Absolutely No Smoking:

Ensure good ventilation: If there is approved ventilation for evacuating fuel fumes then this must be used.

Wear protective gloves: Prolonged exposure of the hands to fuel can cause irritation to the skin.

Wear protective goggles.

IMPORTANT: Be particulary observant regarding cleanliness when working on the fuel system. Loss of function may occur due to very small particles. Prevent dirt and grime from entering the fuel system by cleaning the connections and plugging pipes and lines during disassembly. Use 82 92 948 Plugs, A/C system assembly. Keep components free from contaminants during storage.

To remove

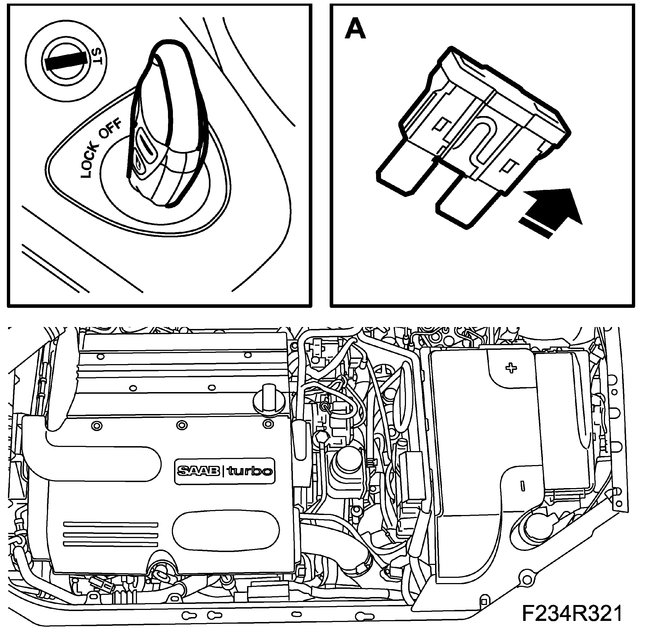

1. Reduce the oil pressure by removing fuse 2 for the fuel pump while the engine is running (fuse 2 is located in the main fuse box in front of the battery). Once the engine has stopped, turn the ignition key to LOCK and refit the fuse (A).

Pic 4

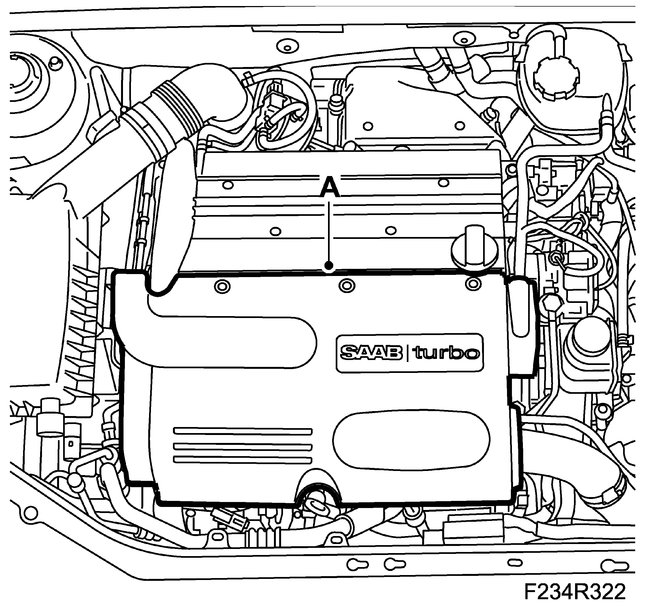

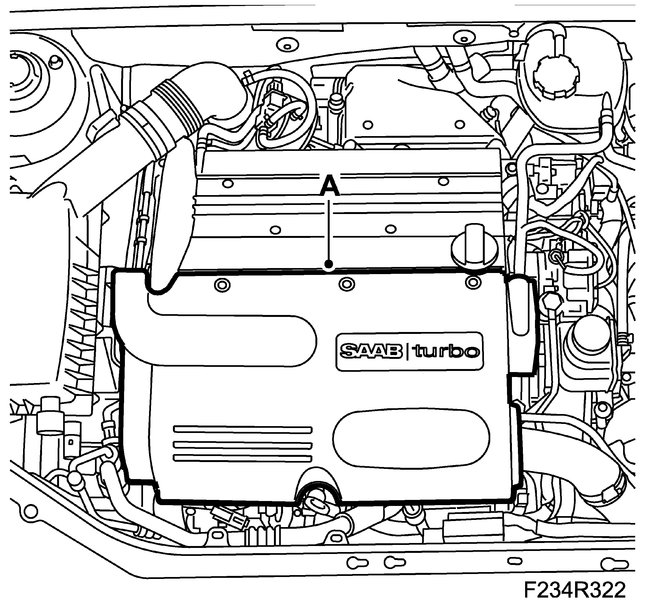

2. Remove the upper engine cover (A).

pic 5

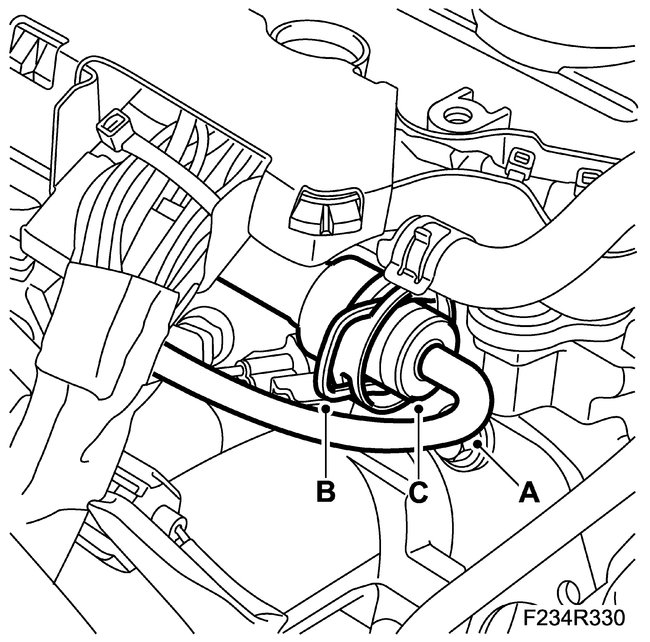

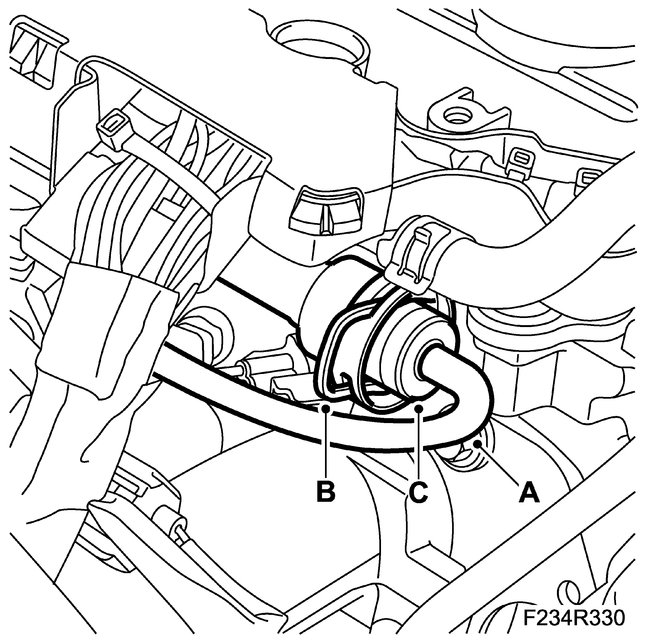

3. Remove the vacuum hose (A).

pic 6

4. Undo the fuel pressure regulator retaining clip (B).

5. Remove the fuel pressure regulator (C). Collect any fuel spill with a rag.

To fit

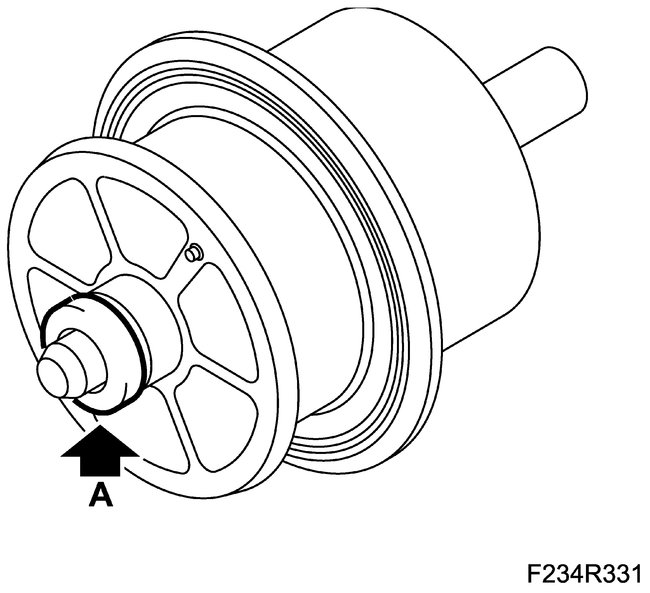

1. Lubricate the O-ring (A) with engine oil.

pic 7

2. Press in the new regulator (C) on the fuel rail and fit the retaining clip (B).

pic 8

3. Connect the vacuum hose (A).

4. Connect an exhaust extractor, start the engine and check its operation. Check for leaks.

5. Replace the upper engine cover.

pic 9

_______________________________

Let me know what you find or if you have other questions.

Take care,

Joe

Images (Click to make bigger)

Sunday, January 27th, 2019 AT 7:37 PM