The timing chain should be plated to identify specific links. Is this a new chain? Let me know that. However, here are the directions I have for alignment and removal and replacement. The attached pics correlate with the directions.

_____________________________________

2011 Volkswagen Routan (7B1) V6-3.6L (CJRA)

Timing Chain And Sprockets

Vehicle Engine, Cooling and Exhaust Engine Timing Components Timing Chain Service and Repair Removal and Replacement Timing Chain And Sprockets

TIMING CHAIN AND SPROCKETS

Timing Chain And Sprockets

Special tools, testers and auxiliary items required

Camshaft Phaser Locks, Right Side (10202-1)

Camshaft Phaser Locks, Left Side (10202-2)

Tensioner Pin (8514)

Removing

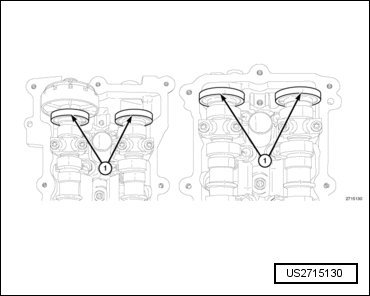

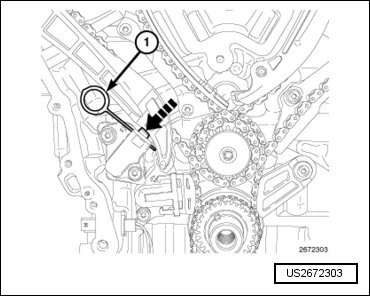

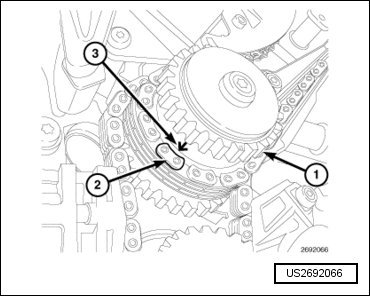

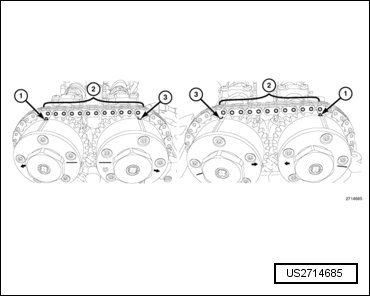

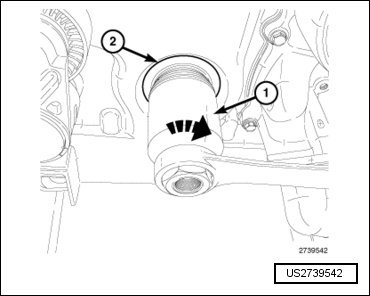

The magnetic timing wheels (1) must not come in contact with magnets (pickup tools, trays, etc.) Or any other strong magnetic field. This will destroy the timing wheels ability to correctly relay camshaft position to the camshaft position sensor.

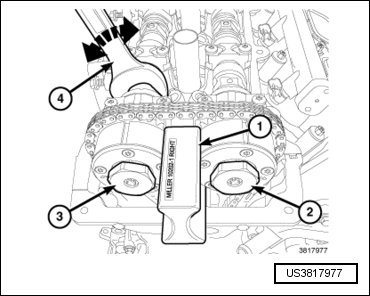

Pic 1

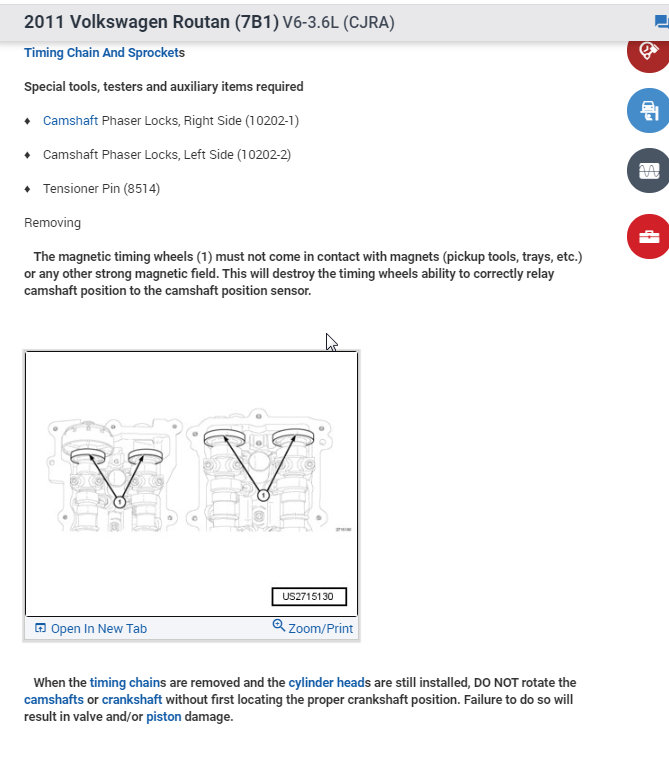

When the timing chains are removed and the cylinder heads are still installed, DO NOT rotate the camshafts or crankshaft without first locating the proper crankshaft position. Failure to do so will result in valve and/or piston damage.

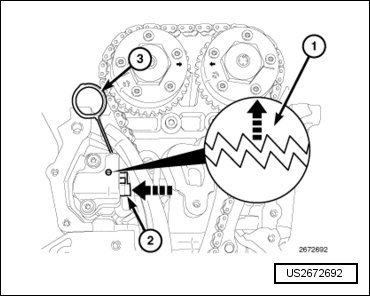

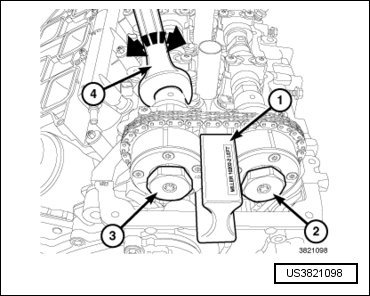

Pic 2

The Variable Valve Timing (VVT) assemblies (Phasers) and Oil Control Valves (OCVs) can be serviced without removing the engine timing cover. Refer to => [ Variable Valve Timing Camshaft Phasers, Left ] See: Variable Valve Timing Actuator > Removal and Replacement > Variable Valve Timing Camshaft Phasers, Left and => [ Variable Valve Timing Camshaft Phasers, Right ] See: Variable Valve Timing Actuator > Removal and Replacement > Variable Valve Timing Camshaft Phasers, Right.

- Disconnect the negative battery cable.

- Remove the air cleaner housing assembly and upper intake manifold. Refer to => [ Upper Intake Manifold ].

- Remove the cylinder head covers. Refer to => [ Left Cylinder Head Cover ] and => [ Right Cylinder Head Cover ].

- Remove the spark plugs. Refer to => [ Spark Plug ] See: Spark Plug > Removal and Replacement > Spark Plug.

- Raise and support the vehicle.

- Drain the engine cooling system. Refer to => [ Cooling System Draining and Filling ] See: Cooling System > Procedures > Cooling System Draining and Filling.

- Remove the oil pan, accessory drive belts, crankshaft vibration damper and engine timing cover. Refer to => [ Engine Timing Cover ] See: Cylinder Head Assembly > Removal and Replacement > Engine Timing Cover.

Take this opportunity to measure timing chain wear. Refer to => [ Measuring Timing Chain Wear ] See: Timing Chain > Component Tests and General Diagnostics > Measuring Timing Chain Wear.

When aligning timing marks, always rotate engine by turning the crankshaft. Failure to do so will result in valve and/or piston damage.

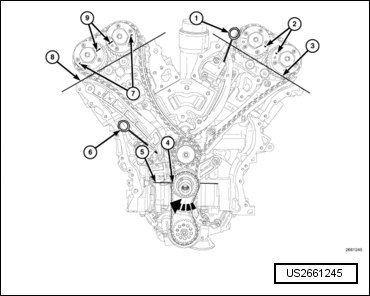

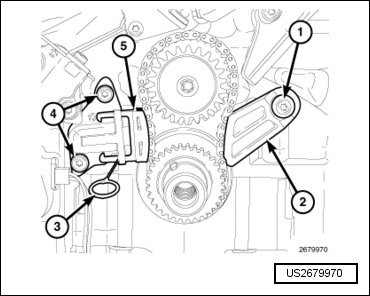

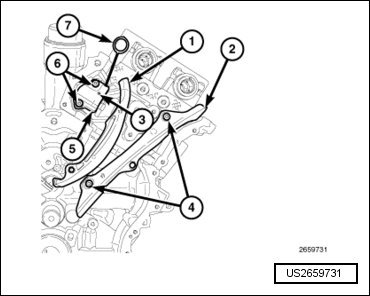

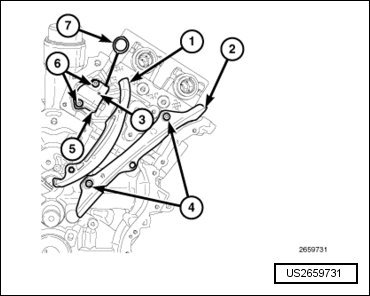

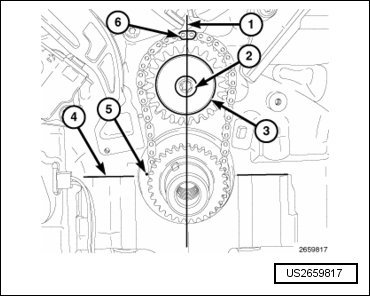

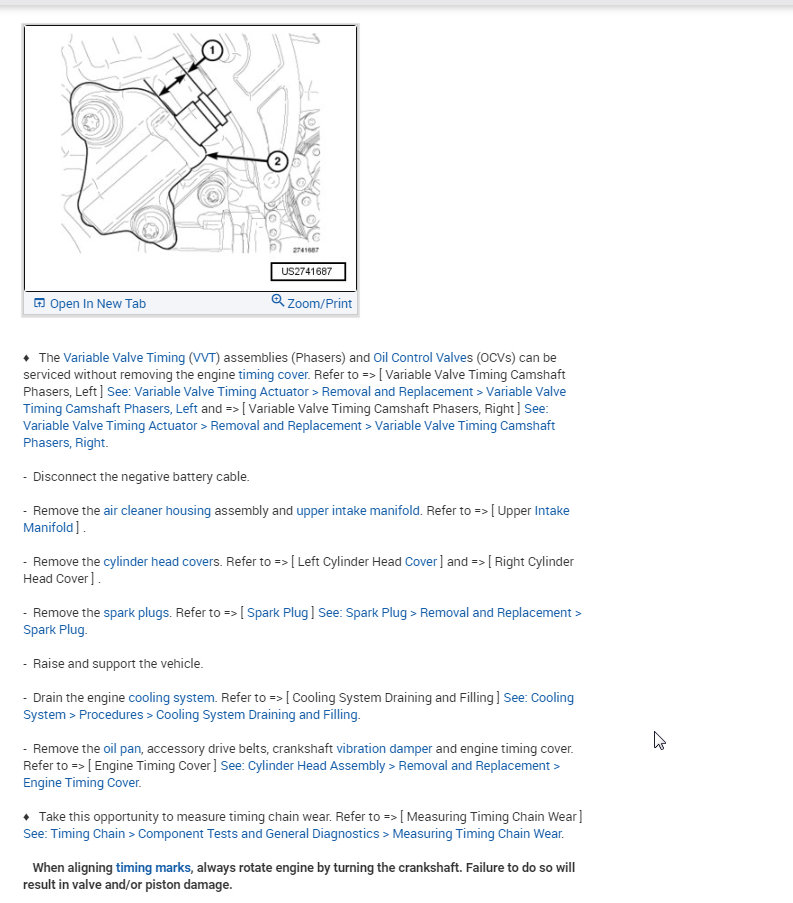

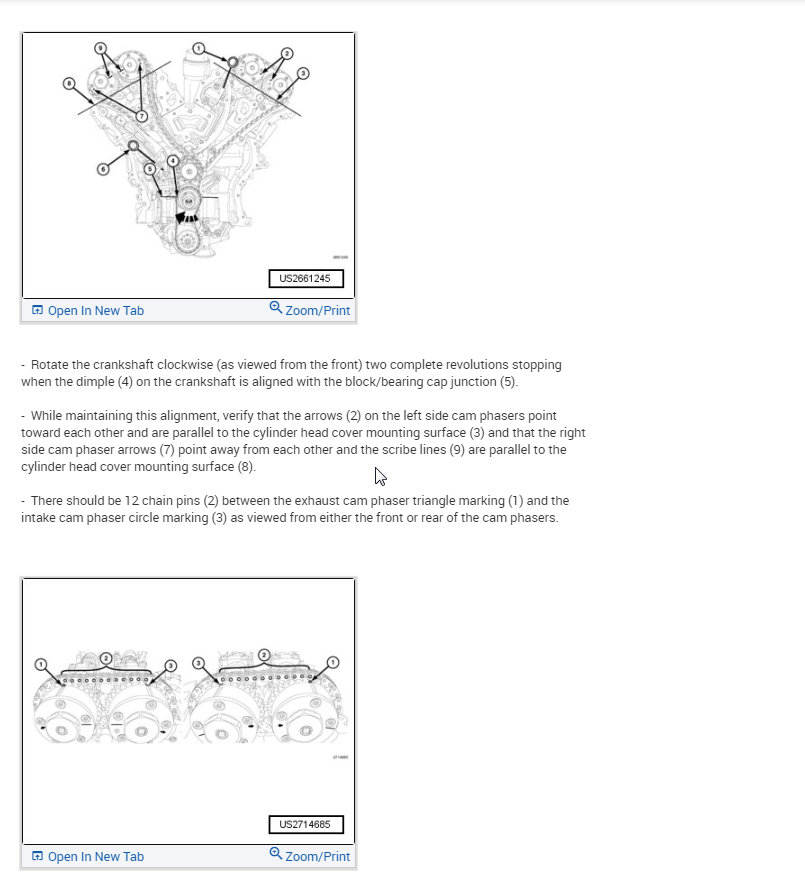

- Rotate the crankshaft clockwise (as viewed from the front) to place the number one cylinder piston at top-dead-center on the exhaust stroke by aligning the dimple (4) on the crankshaft with the block/bearing cap junction (5).

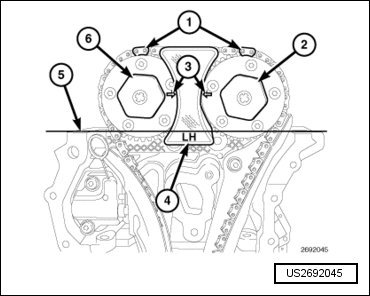

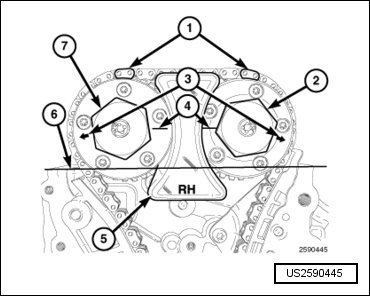

- While maintaining this alignment, verify that the arrows (2) on the left side cam phasers point toward each other and are parallel to the cylinder head cover mounting surface (3) and that the right side cam phaser arrows (7) point away from each other and the scribe lines(9) are parallel to the cylinder head cover mounting surface.

Pic 3

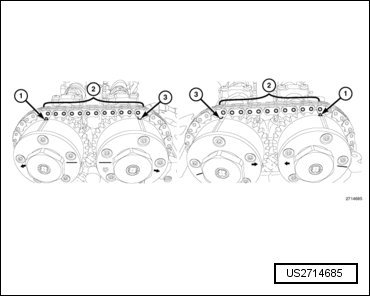

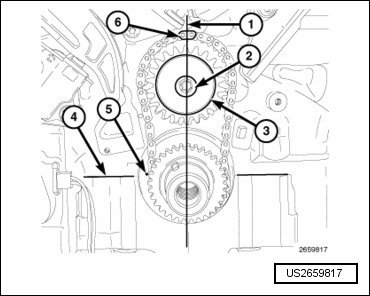

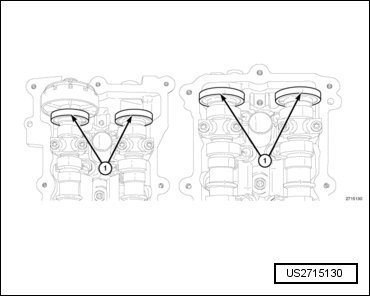

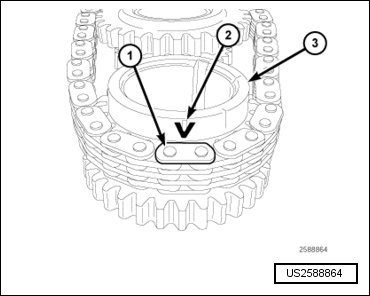

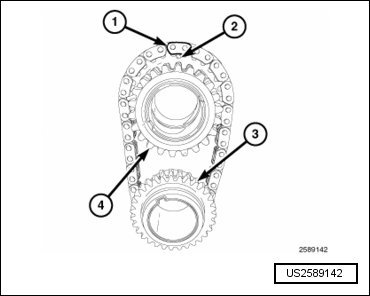

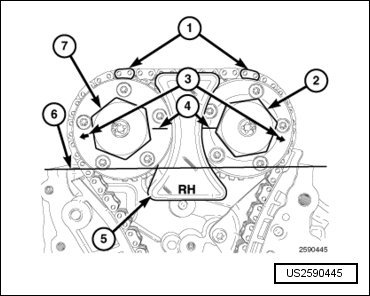

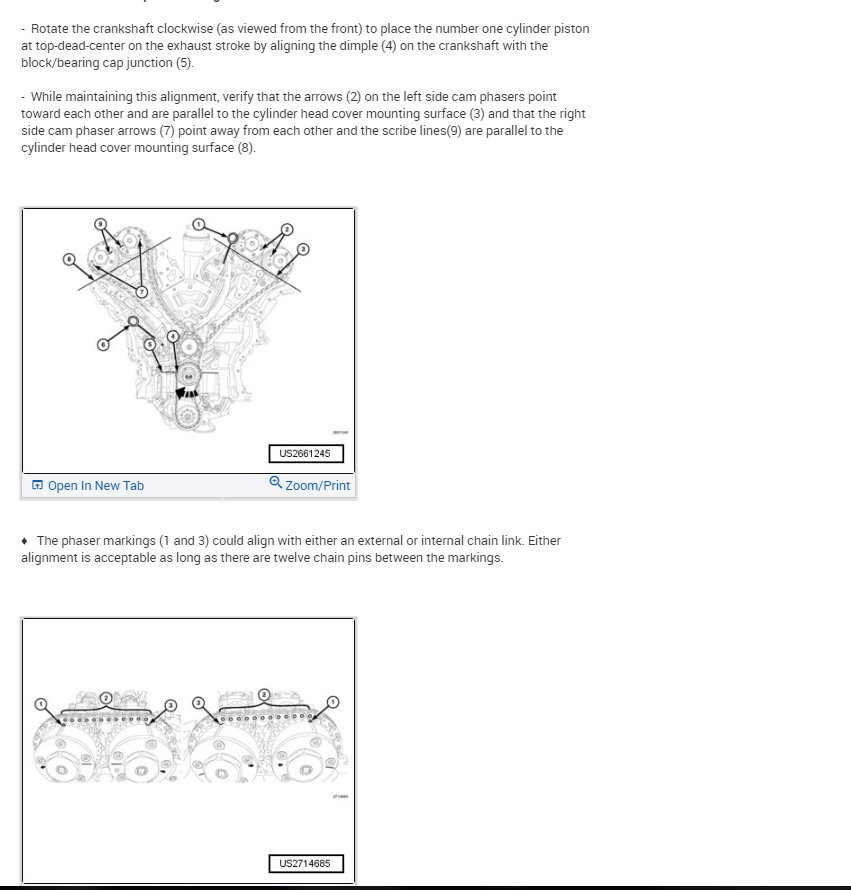

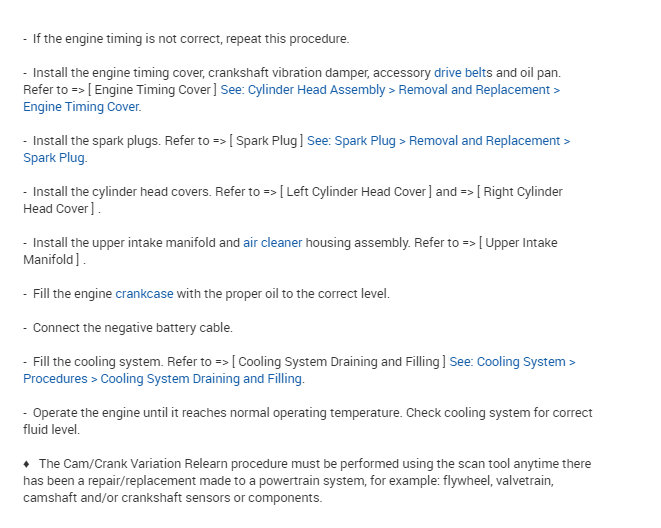

The phaser markings (1 and 3) could align with either an external or internal chain link. Either alignment is acceptable as long as there are twelve chain pins between the markings.

Pic 4

- There should be twelve chain pins (2) between the exhaust cam phaser triangle marking (1) and the intake cam phaser circle marking (3) as viewed from either the front or rear of the cam phasers.

Always reinstall timing chains so that they maintain the same direction of rotation. Inverting a previously run chain on a previously run sprocket will result in excessive wear to both the chain and sprocket.

- Mark the direction of rotation on the following timing chains using a paint pen or equivalent to aid in reassembly:

Left side cam chain

Right side cam chain

Oil pump chain

Primary chain

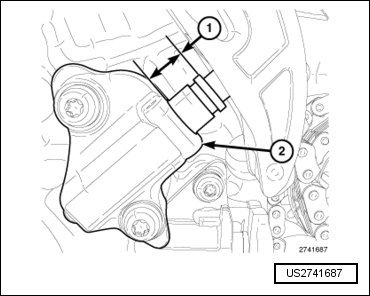

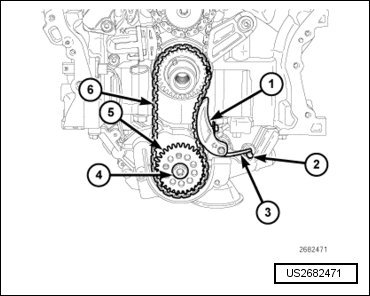

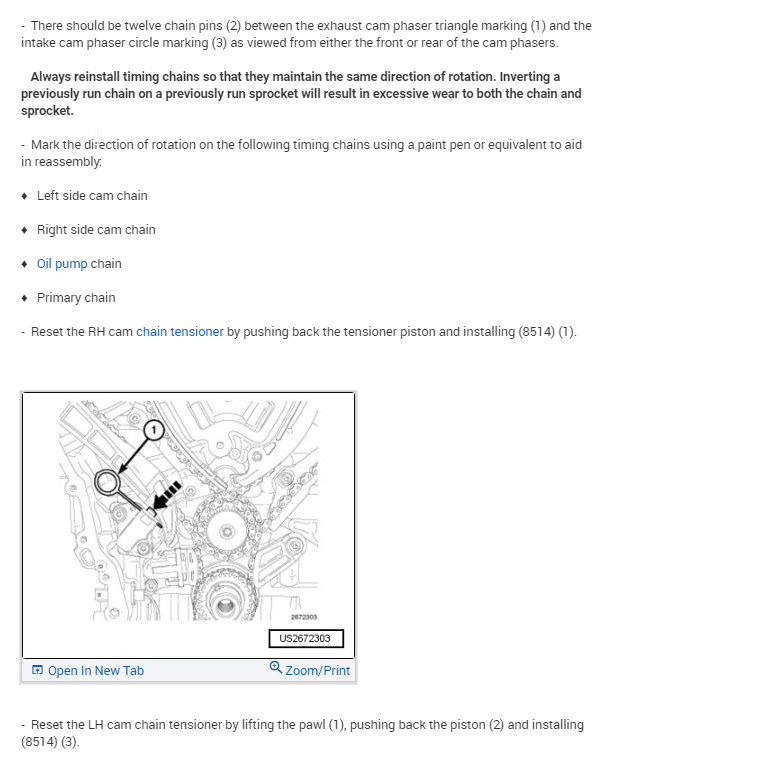

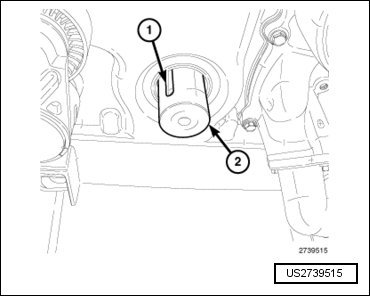

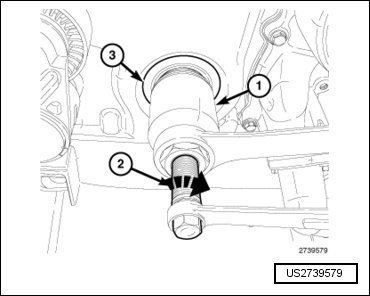

- Reset the RH cam chain tensioner by pushing back the tensioner piston and installing (8514) (1).

Pic 5

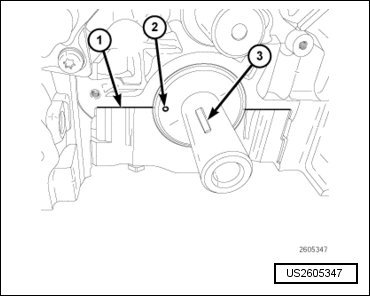

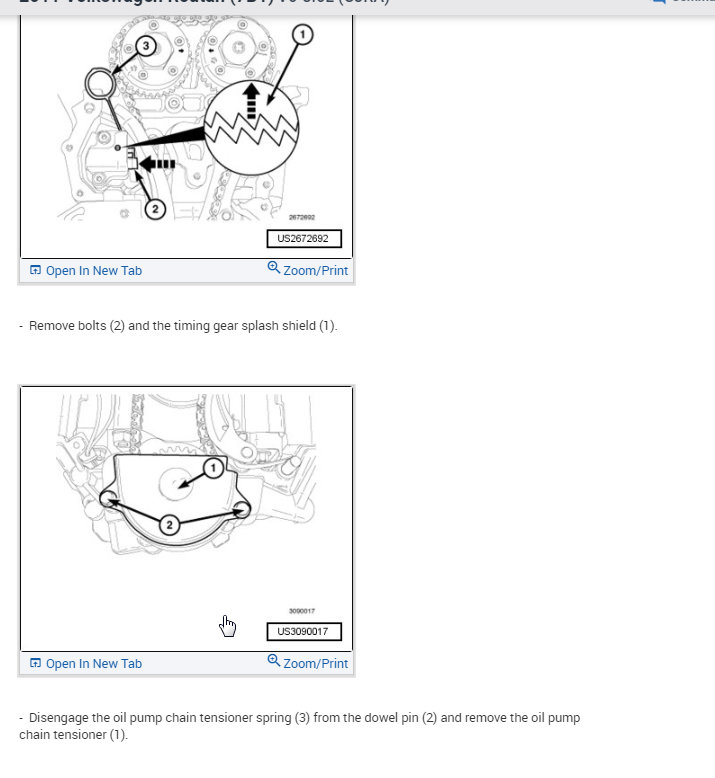

- Reset the LH cam chain tensioner by lifting the pawl (1), pushing back the piston (2) and installing (8514) (3).

Pic 6

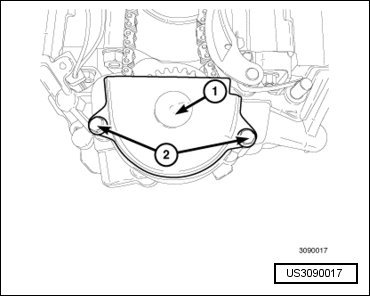

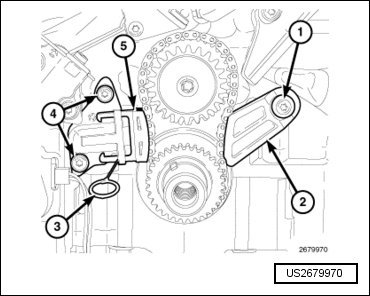

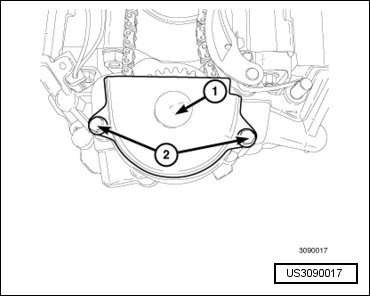

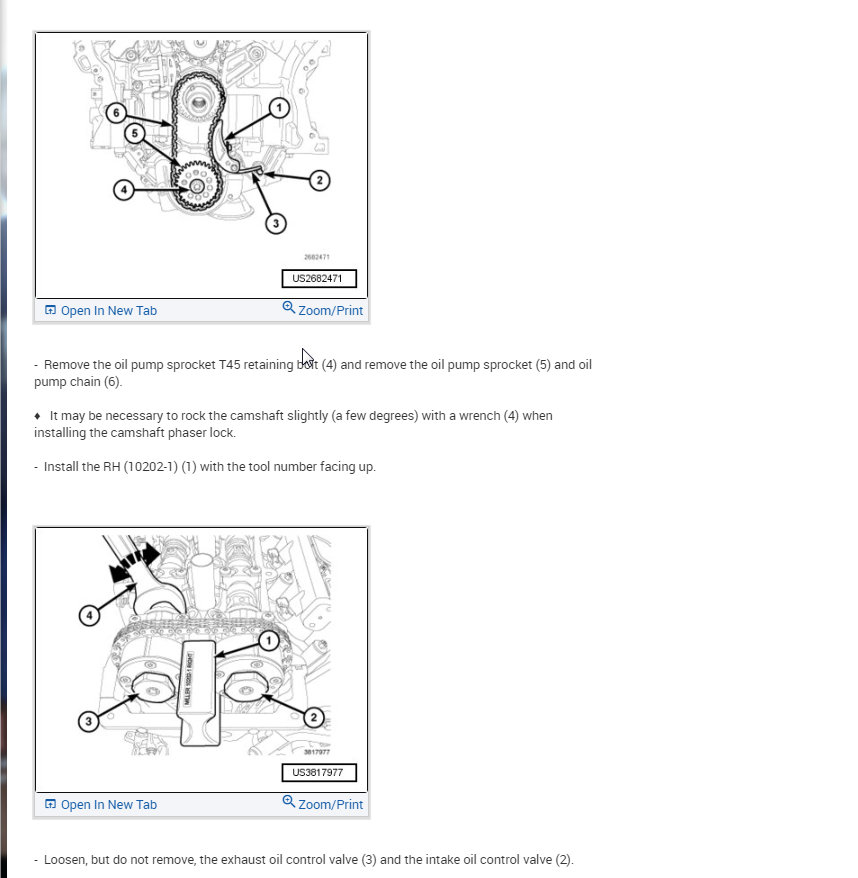

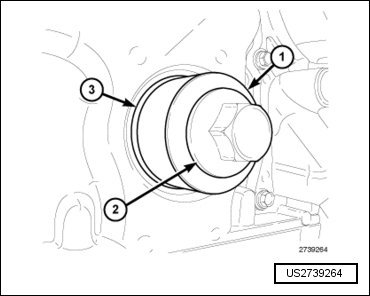

- Remove bolts (2) and the timing gear splash shield (1).

Pic 7

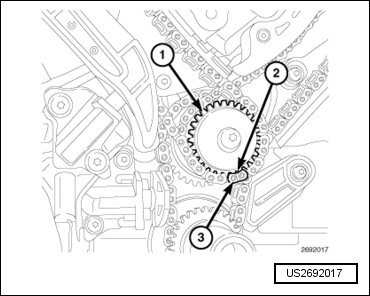

- Disengage the oil pump chain tensioner spring (3) from the dowel pin (2) and remove the oil pump chain tensioner (1).

Pic 8

- Remove the oil pump sprocket T45 retaining bolt (4) and remove the oil pump sprocket (5) and oil pump chain (6).

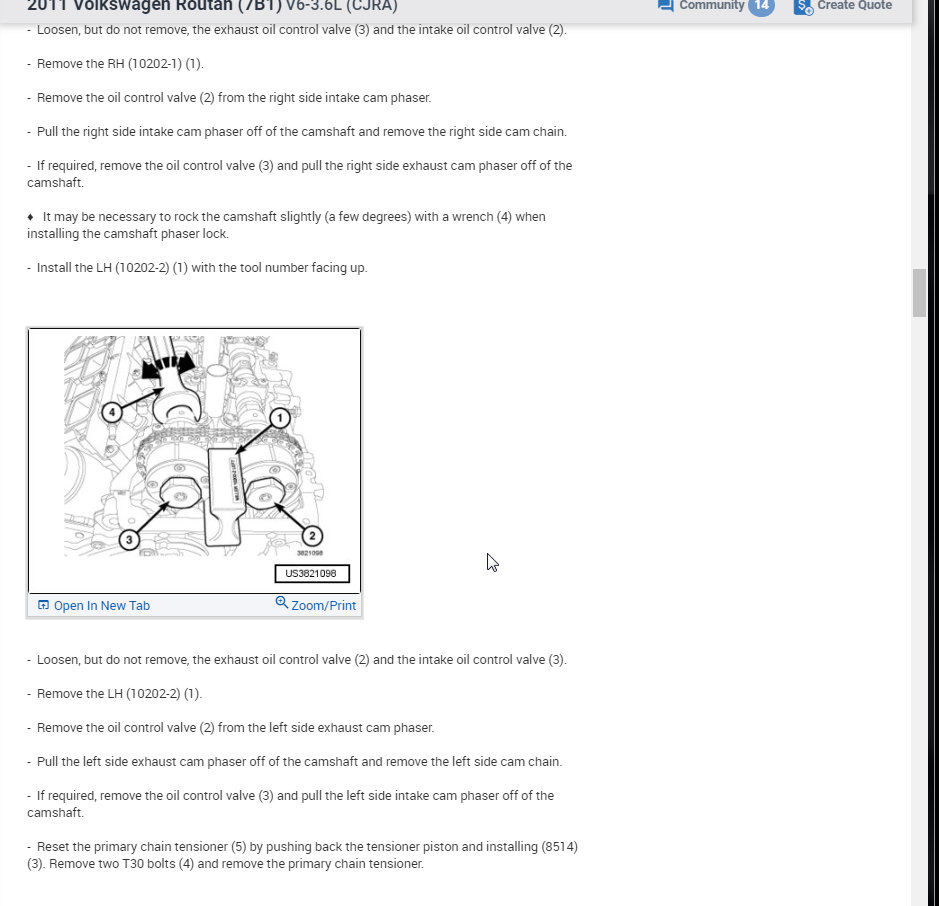

It may be necessary to rock the camshaft slightly (a few degrees) with a wrench (4) when installing the camshaft phaser lock.

- Install the RH (10202-1) (1) with the tool number facing up.

Pic 9

- Loosen, but do not remove, the exhaust oil control valve (3) and the intake oil control valve (2).

- Remove the RH (10202-1) (1).

- Remove the oil control valve (2) from the right side intake cam phaser.

- Pull the right side intake cam phaser off of the camshaft and remove the right side cam chain.

- If required, remove the oil control valve (3) and pull the right side exhaust cam phaser off of the camshaft.

It may be necessary to rock the camshaft slightly (a few degrees) with a wrench (4) when installing the camshaft phaser lock.

- Install the LH (10202-2) (1) with the tool number facing up.

Pic 10

- Loosen, but do not remove, the exhaust oil control valve (2) and the intake oil control valve (3).

- Remove the LH (10202-2) (1).

- Remove the oil control valve (2) from the left side exhaust cam phaser.

- Pull the left side exhaust cam phaser off of the camshaft and remove the left side cam chain.

- If required, remove the oil control valve (3) and pull the left side intake cam phaser off of the camshaft.

- Reset the primary chain tensioner (5) by pushing back the tensioner piston and installing (8514) (3). Remove two T30 bolts (4) and remove the primary chain tensioner.

Pic 11

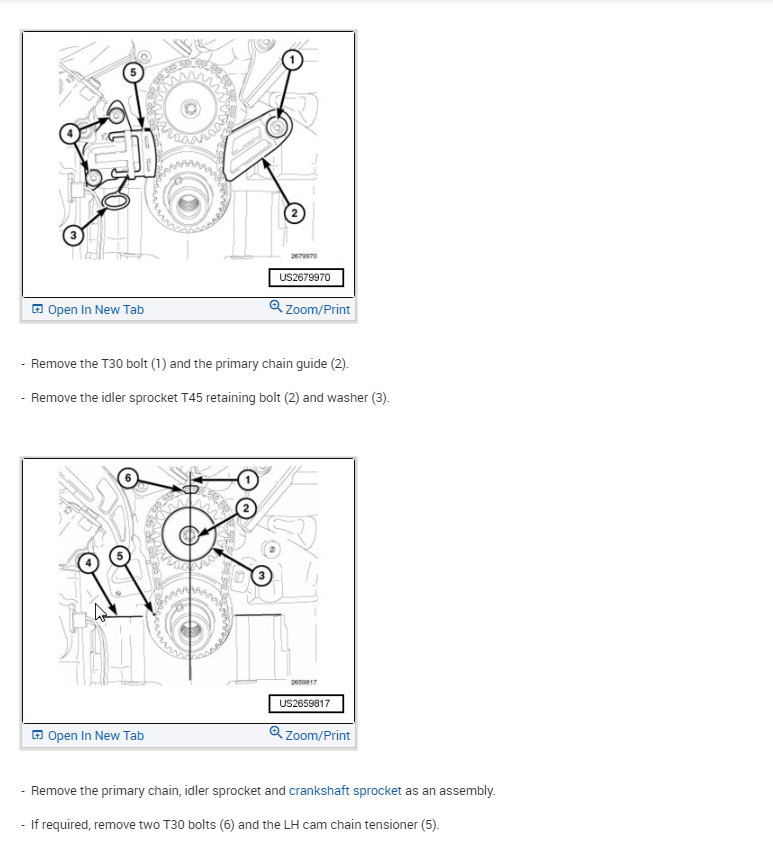

- Remove the T30 bolt (1) and the primary chain guide (2).

- Remove the idler sprocket T45 retaining bolt (2) and washer (3).

Pic 12

- Remove the primary chain, idler sprocket and crankshaft sprocket as an assembly.

- If required, remove two T30 bolts (6) and the LH cam chain tensioner (5).

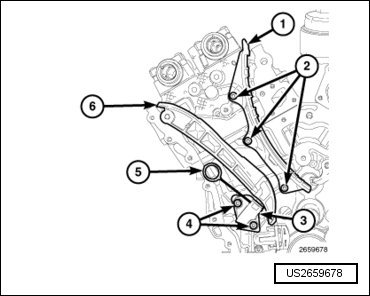

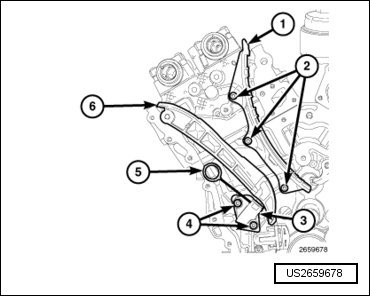

Pic 13

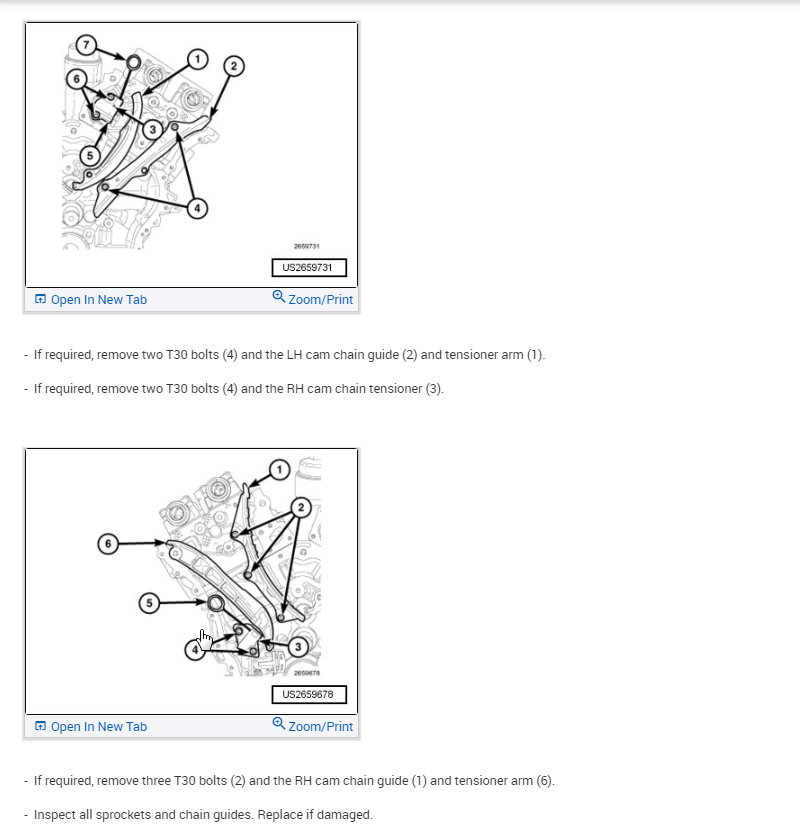

- If required, remove two T30 bolts (4) and the LH cam chain guide (2) and tensioner arm (1).

- If required, remove two T30 bolts (4) and the RH cam chain tensioner (3).

Pic 14

- If required, remove three T30 bolts (2) and the RH cam chain guide (1) and tensioner arm (6).

- Inspect all sprockets and chain guides. Replace if damaged.

Installing

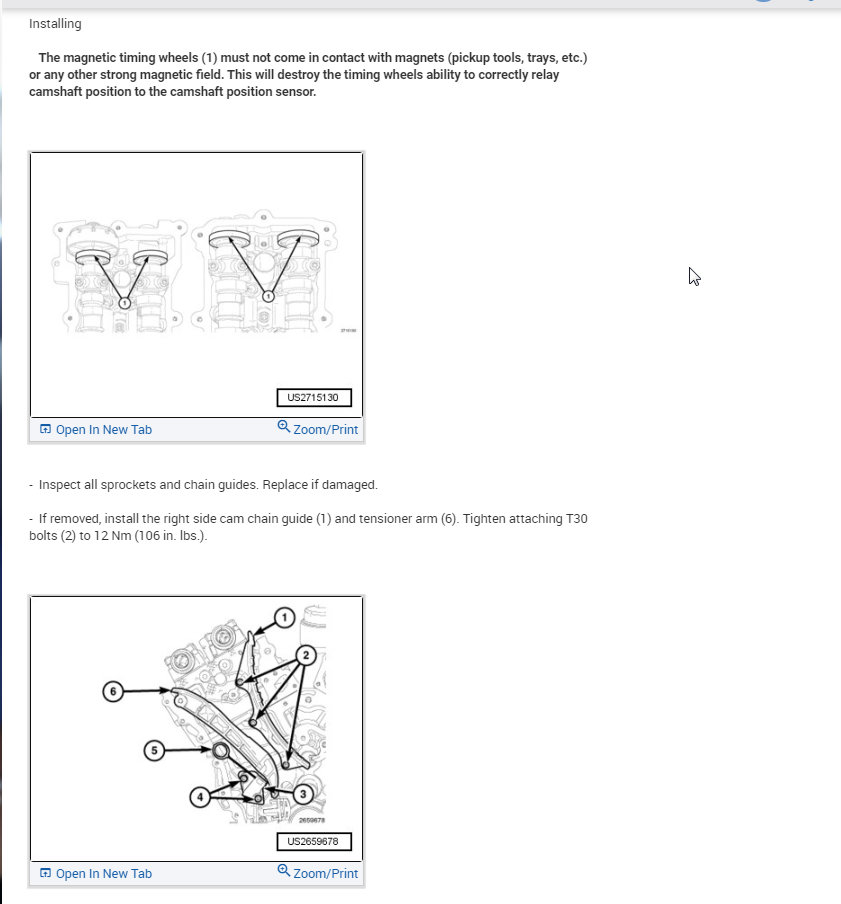

The magnetic timing wheels (1) must not come in contact with magnets (pickup tools, trays, etc.) Or any other strong magnetic field. This will destroy the timing wheels ability to correctly relay camshaft position to the camshaft position sensor.

Pic 15

- Inspect all sprockets and chain guides. Replace if damaged.

- If removed, install the right side cam chain guide (1) and tensioner arm (6). Tighten attaching T30 bolts (2) to 12 Nm (106 in. Lbs.).

Pic 16

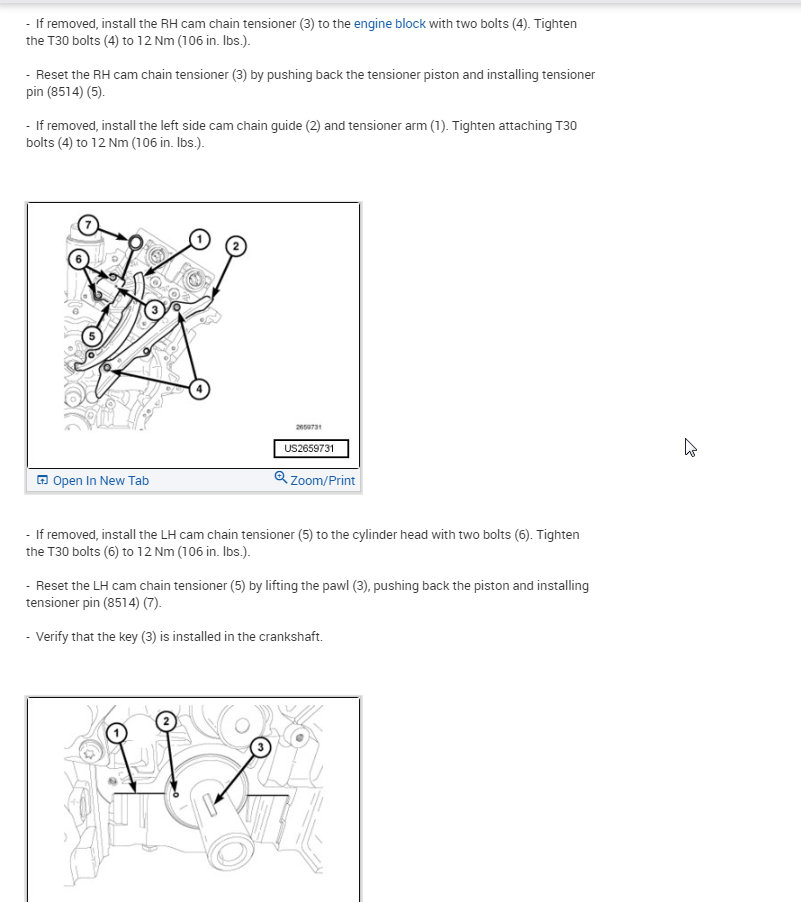

- If removed, install the RH cam chain tensioner (3) to the engine block with two bolts (4). Tighten the T30 bolts (4) to 12 Nm (106 in. Lbs.).

- Reset the RH cam chain tensioner (3) by pushing back the tensioner piston and installing tensioner pin (8514) (5).

- If removed, install the left side cam chain guide (2) and tensioner arm (1). Tighten attaching T30 bolts (4) to 12 Nm (106 in. Lbs.).

Pic 17

- If removed, install the LH cam chain tensioner (5) to the cylinder head with two bolts (6). Tighten the T30 bolts (6) to 12 Nm (106 in. Lbs.).

- Reset the LH cam chain tensioner (5) by lifting the pawl (3), pushing back the piston and installing tensioner pin (8514) (7).

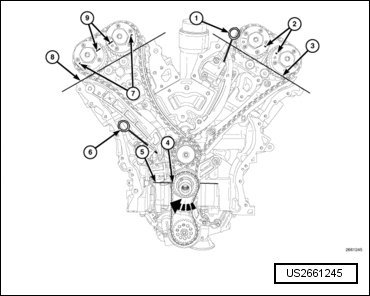

- Verify that the key (3) is installed in the crankshaft.

Pic 18

Do not rotate the crankshaft more than a few degrees independently of the camshafts. Piston to valve contact could occur resulting in possible valve damage. If the crankshaft needs to be rotated more than a few degrees, first remove the camshafts. Refer to => [ Left Camshafts ] See: Camshaft, Engine > Removal and Replacement > Left Camshafts or => [ Right Camshafts ] See: Camshaft, Engine > Removal and Replacement > Right Camshafts.

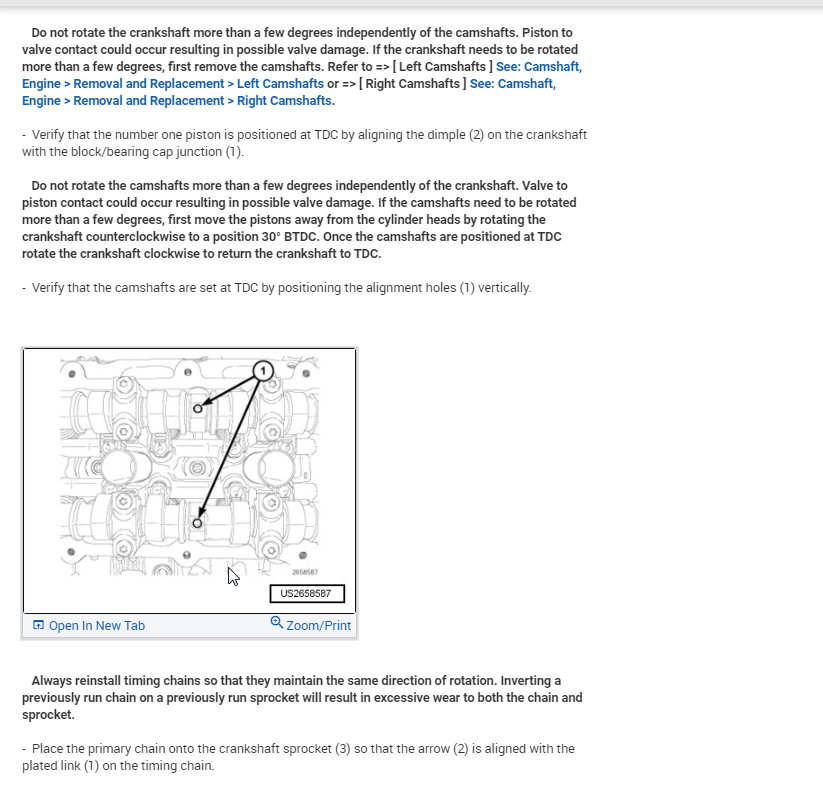

- Verify that the number one piston is positioned at TDC by aligning the dimple (2) on the crankshaft with the block/bearing cap junction (1).

Do not rotate the camshafts more than a few degrees independently of the crankshaft. Valve to piston contact could occur resulting in possible valve damage. If the camshafts need to be rotated more than a few degrees, first move the pistons away from the cylinder heads by rotating the crankshaft counterclockwise to a position 30° BTDC. Once the camshafts are positioned at TDC rotate the crankshaft clockwise to return the crankshaft to TDC.

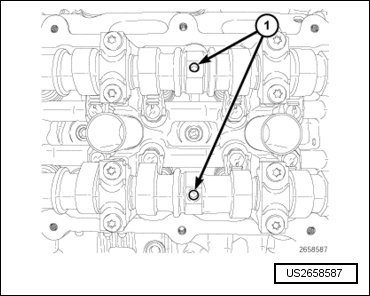

- Verify that the camshafts are set at TDC by positioning the alignment holes (1) vertically.

Pic 19

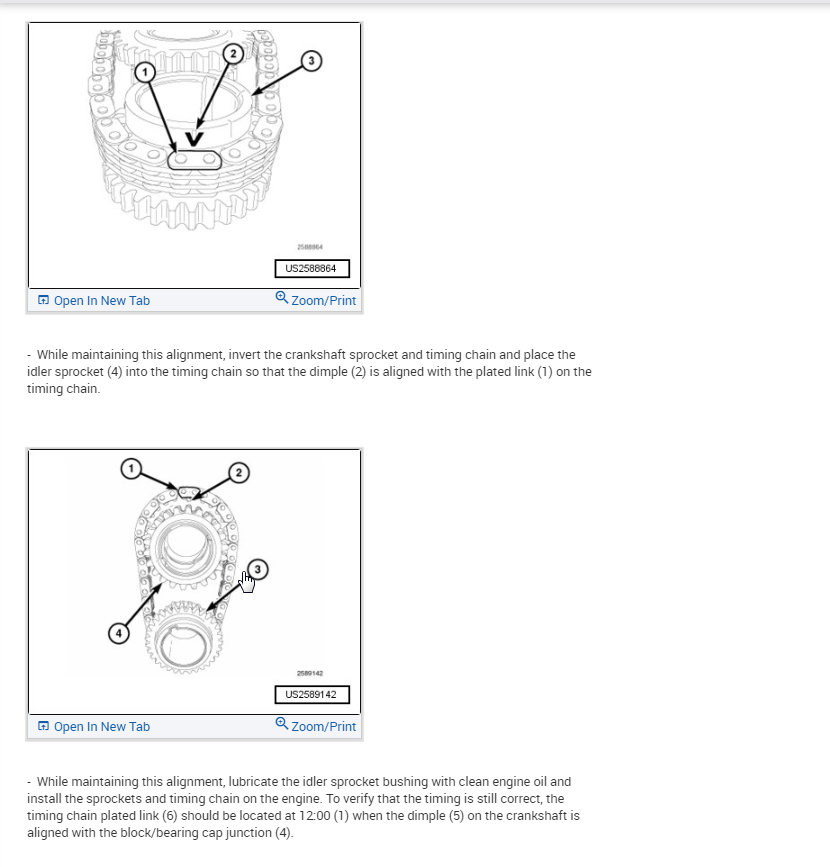

Always reinstall timing chains so that they maintain the same direction of rotation. Inverting a previously run chain on a previously run sprocket will result in excessive wear to both the chain and sprocket.

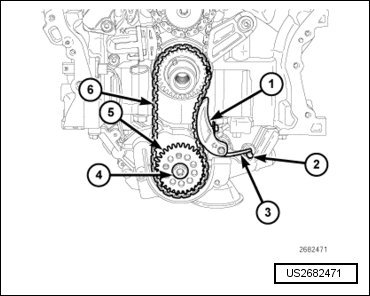

- Place the primary chain onto the crankshaft sprocket (3) so that the arrow (2) is aligned with the plated link (1) on the timing chain.

Pic 20

- While maintaining this alignment, invert the crankshaft sprocket and timing chain and place the idler sprocket (4) into the timing chain so that the dimple (2) is aligned with the plated link (1) on the timing chain.

Pic 21

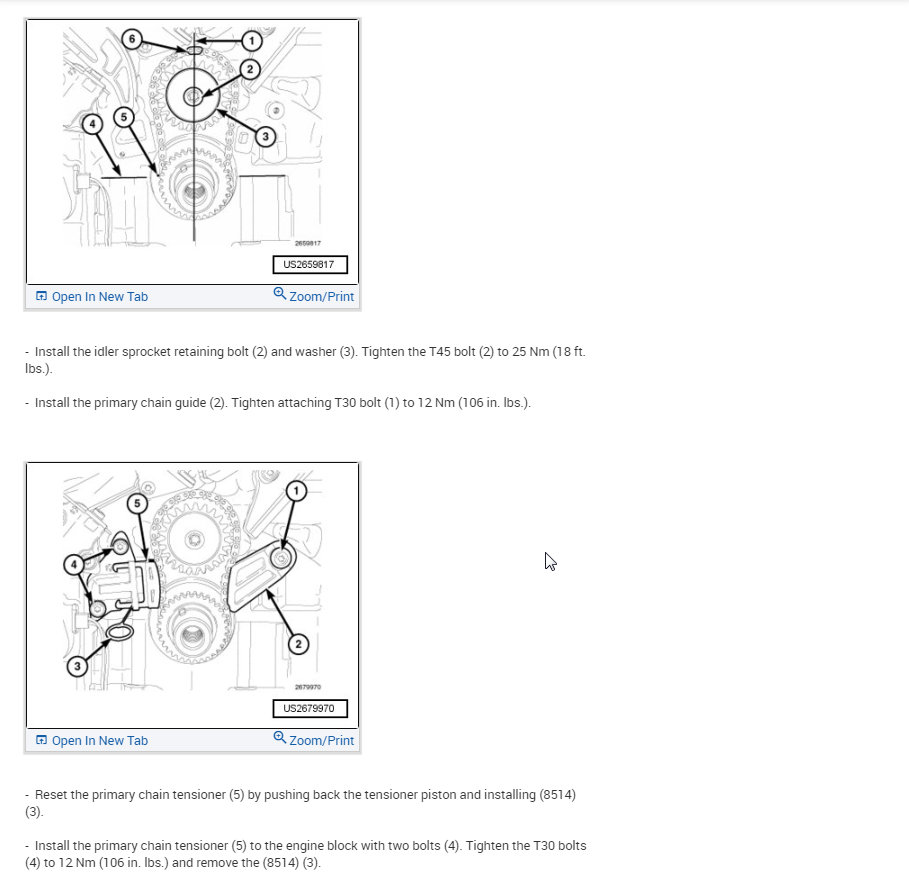

- While maintaining this alignment, lubricate the idler sprocket bushing with clean engine oil and install the sprockets and timing chain on the engine. To verify that the timing is still correct, the timing chain plated link (6) should be located at 12:00 (1) when the dimple (5) on the crankshaft is aligned with the block/bearing cap junction (4).

Pic 22

- Install the idler sprocket retaining bolt (2) and washer (3). Tighten the T45 bolt (2) to 25 Nm (18 ft. Lbs.).

- Install the primary chain guide (2). Tighten attaching T30 bolt (1) to 12 Nm (106 in. Lbs.).

Pic 23

- Reset the primary chain tensioner (5) by pushing back the tensioner piston and installing (8514) (3).

- Install the primary chain tensioner (5) to the engine block with two bolts (4). Tighten the T30 bolts (4) to 12 Nm (106 in. Lbs.) And remove the (8514) (3).

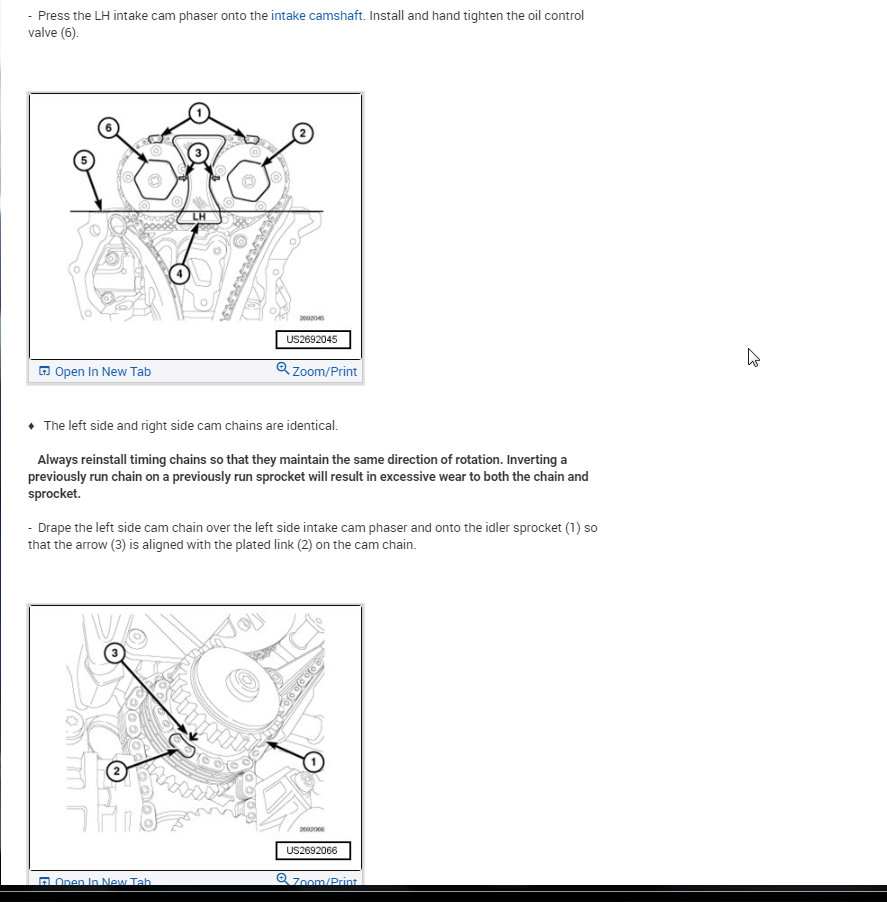

- Press the LH intake cam phaser onto the intake camshaft. Install and hand tighten the oil control valve (6).

Pic 24

The left side and right side cam chains are identical.

Always reinstall timing chains so that they maintain the same direction of rotation. Inverting a previously run chain on a previously run sprocket will result in excessive wear to both the chain and sprocket.

- Drape the left side cam chain over the left side intake cam phaser and onto the idler sprocket (1) so that the arrow (3) is aligned with the plated link (2) on the cam chain.

Pic 25

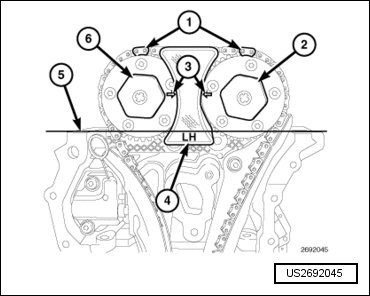

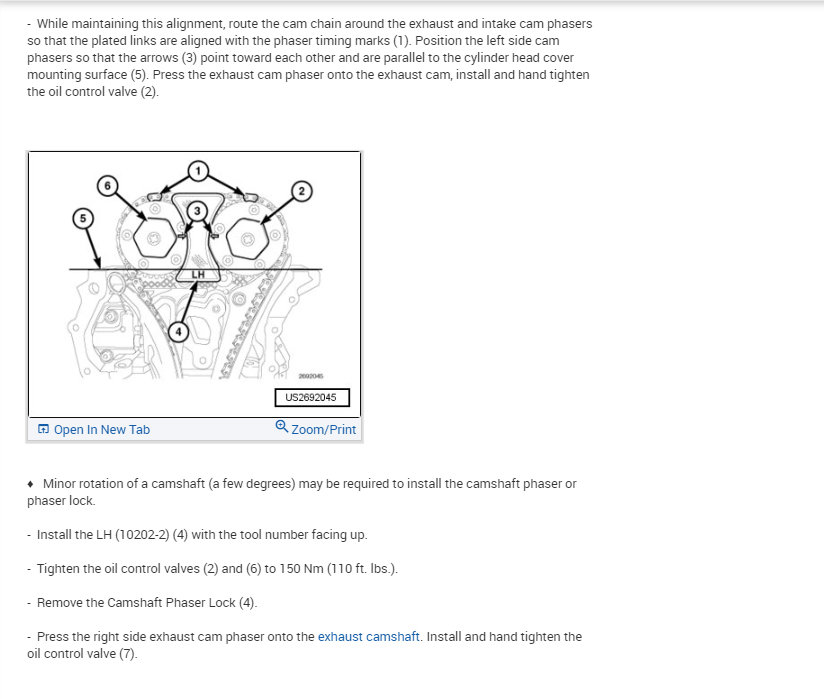

- While maintaining this alignment, route the cam chain around the exhaust and intake cam phasers so that the plated links are aligned with the phaser timing marks (1). Position the left side cam phasers so that the arrows (3) point toward each other and are parallel to the cylinder head cover mounting surface (5). Press the exhaust cam phaser onto the exhaust cam, install and hand tighten the oil control valve (2).

Pic 26

Minor rotation of a camshaft (a few degrees) may be required to install the camshaft phaser or phaser lock.

- Install the LH (10202-2) (4) with the tool number facing up.

- Tighten the oil control valves (2) and (6) to 150 Nm (110 ft. Lbs.).

- Remove the Camshaft Phaser Lock (4).

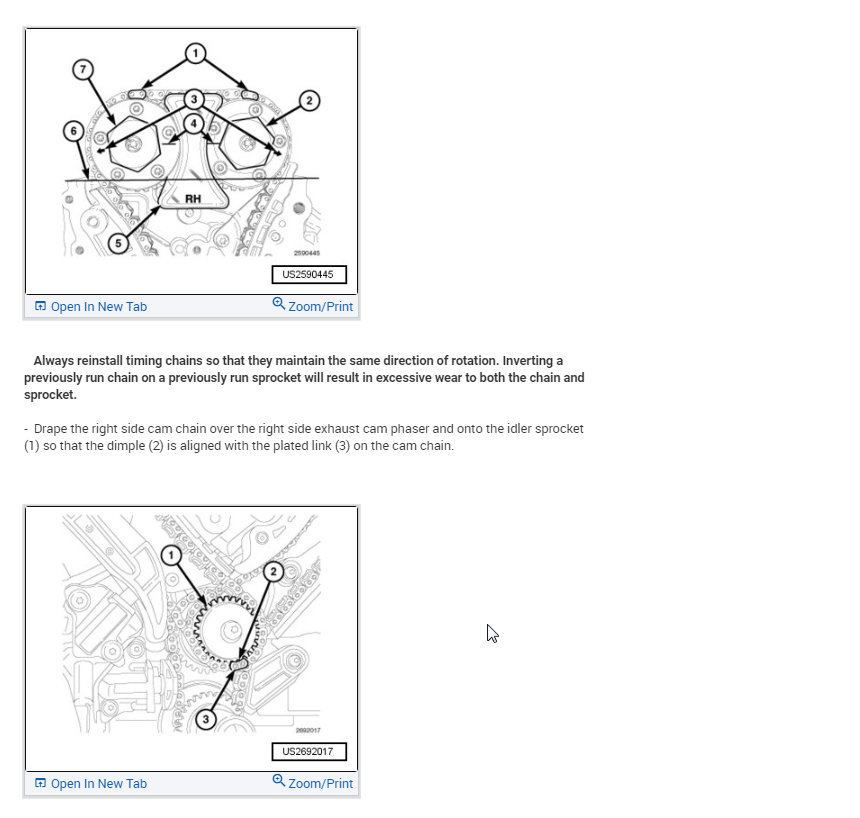

- Press the right side exhaust cam phaser onto the exhaust camshaft. Install and hand tighten the oil control valve (7).

Pic 27

Always reinstall timing chains so that they maintain the same direction of rotation. Inverting a previously run chain on a previously run sprocket will result in excessive wear to both the chain and sprocket.

- Drape the right side cam chain over the right side exhaust cam phaser and onto the idler sprocket (1) so that the dimple (2) is aligned with the plated link (3) on the cam chain.

Pic 28

- While maintaining this alignment, route the cam chain around the exhaust and intake cam phasers so that the plated links are aligned with the phaser timing marks (1). Position the right side cam phasers so that the arrows (3) point away from each other and the scribe lines (4) are parallel to the cylinder head cover mounting surface (6). Press the intake cam phaser onto the intake cam, install and hand tighten the oil control valve (2).

Pic 29

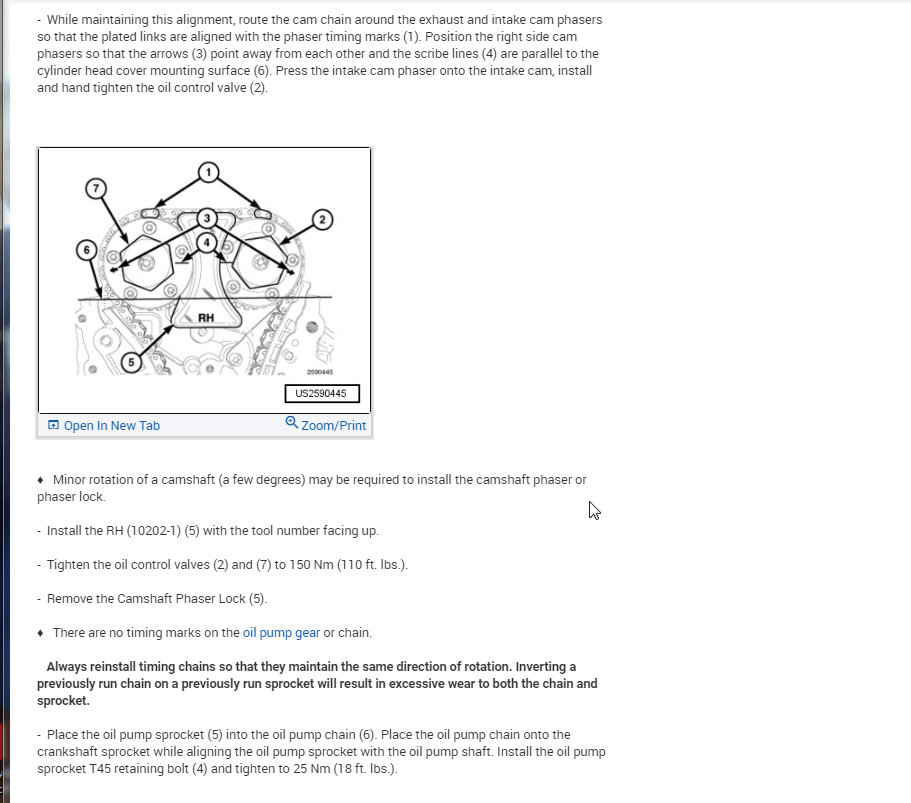

Minor rotation of a camshaft (a few degrees) may be required to install the camshaft phaser or phaser lock.

- Install the RH (10202-1) (5) with the tool number facing up.

- Tighten the oil control valves (2) and (7) to 150 Nm (110 ft. Lbs.).

- Remove the Camshaft Phaser Lock (5).

There are no timing marks on the oil pump gear or chain.

Always reinstall timing chains so that they maintain the same direction of rotation. Inverting a previously run chain on a previously run sprocket will result in excessive wear to both the chain and sprocket.

- Place the oil pump sprocket (5) into the oil pump chain (6). Place the oil pump chain onto the crankshaft sprocket while aligning the oil pump sprocket with the oil pump shaft. Install the oil pump sprocket T45 retaining bolt (4) and tighten to 25 Nm (18 ft. Lbs.).

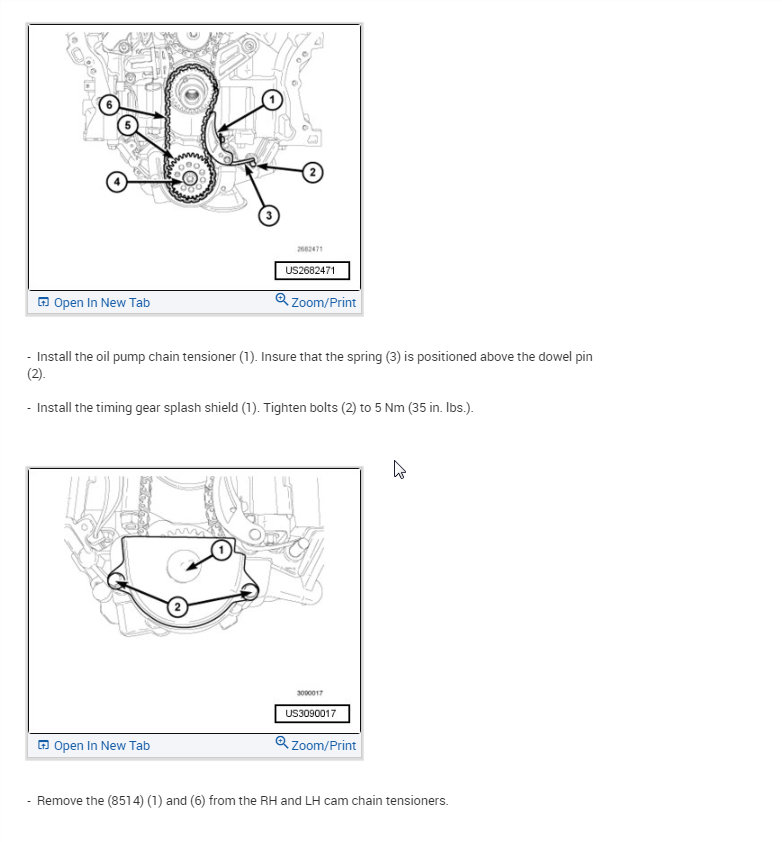

Pic 30

- Install the oil pump chain tensioner (1). Insure that the spring (3) is positioned above the dowel pin (2).

- Install the timing gear splash shield (1). Tighten bolts (2) to 5 Nm (35 in. Lbs.).

Pic 31

- Remove the (8514) (1) and (6) from the RH and LH cam chain tensioners.

Pic 32

- Rotate the crankshaft clockwise (as viewed from the front) two complete revolutions stopping when the dimple (4) on the crankshaft is aligned with the block/bearing cap junction (5).

- While maintaining this alignment, verify that the arrows (2) on the left side cam phasers point toward each other and are parallel to the cylinder head cover mounting surface (3) and that the right side cam phaser arrows (7) point away from each other and the scribe lines (9) are parallel to the cylinder head cover mounting surface (8).

- There should be 12 chain pins (2) between the exhaust cam phaser triangle marking (1) and the intake cam phaser circle marking (3) as viewed from either the front or rear of the cam phasers.

Pic 33

- If the engine timing is not correct, repeat this procedure.

- Install the engine timing cover, crankshaft vibration damper, accessory drive belts and oil pan. Refer to => [ Engine Timing Cover ] See: Cylinder Head Assembly > Removal and Replacement > Engine Timing Cover.

- Install the spark plugs. Refer to => [ Spark Plug ] See: Spark Plug > Removal and Replacement > Spark Plug.

- Install the cylinder head covers. Refer to => [ Left Cylinder Head Cover ] and => [ Right Cylinder Head Cover ].

- Install the upper intake manifold and air cleaner housing assembly. Refer to => [ Upper Intake Manifold ].

- Fill the engine crankcase with the proper oil to the correct level.

- Connect the negative battery cable.

- Fill the cooling system. Refer to => [ Cooling System Draining and Filling ] See: Cooling System > Procedures > Cooling System Draining and Filling.

- Operate the engine until it reaches normal operating temperature. Check cooling system for correct fluid level.

The Cam/Crank Variation Relearn procedure must be performed using the scan tool anytime there has been a repair/replacement made to a powertrain system, for example: flywheel, valvetrain, camshaft and/or crankshaft sensors or components.

____________________

Let me know if this helps answer any of your questions.

Take care,

Joe

Images (Click to make bigger)

Tuesday, February 18th, 2020 AT 5:10 PM