The battery light means the charging system is not powering the electrical system. The engine is running on the battery until it slowly runs down in less than an hour.

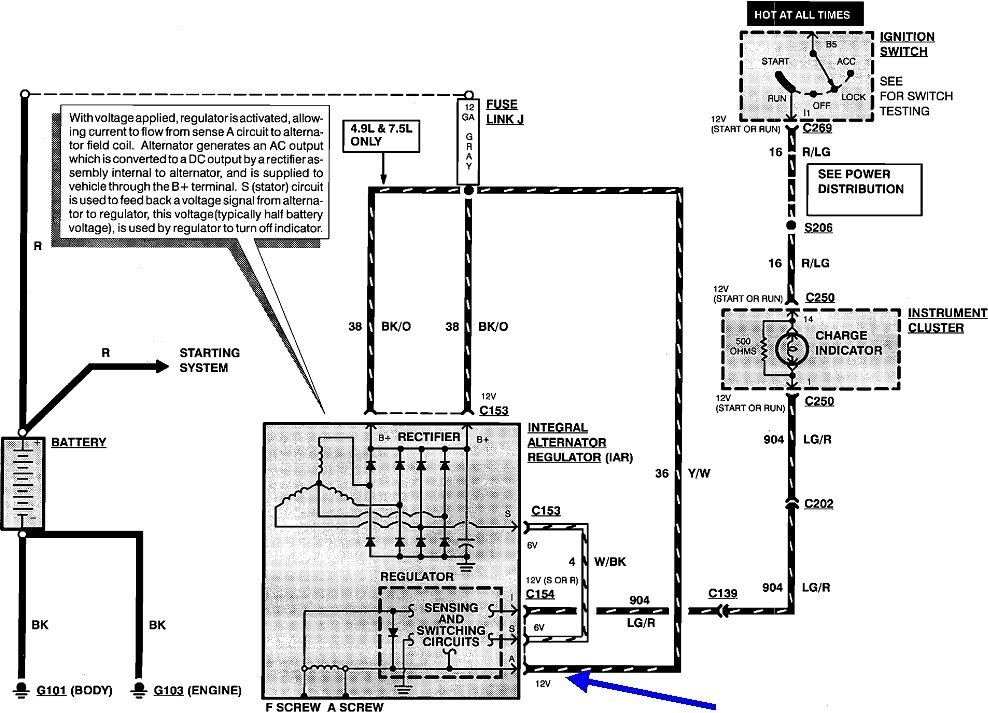

The warning light circuit actually is the "turn-on" signal circuit that tells the voltage regulator when to turn on. The fact that light is on tells us that circuit is okay.

A good place to start is by checking for 12 volts on the yellow / white wire in the plug on the back of the generator. To be valid, that must be done with the plug connected. Back-probe through the rubber weather seal alongside that wire. For this type of problem, an old-style, inexpensive test light with an incandescent bulb can be more accurate, but if all you have is a voltmeter, that will work too. The ignition switch can be off during this test. Let me know what you find.

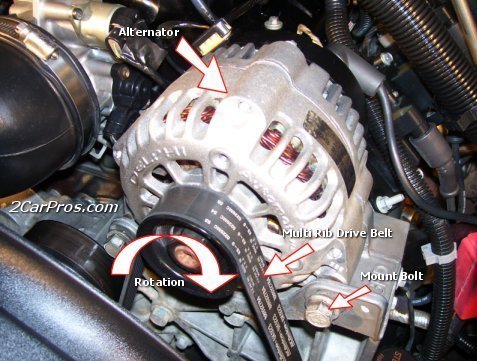

If you do find 12 volts on the yellow / white wire, see if you can get to the voltage regulator mounted on the back of the generator. The second photo shows what it looks like. The blue arrow is pointing to a test point. Start the engine, then use a piece of wire, a stretched-out paper clip, or a small jumper wire to ground that screw. It's useful to have the head lights on during this test, otherwise, connect a voltmeter to the battery so you can see what happens to the charging voltage when you ground that screw. If you see the head lights get noticeably brighter, or the voltage jumps up to more than 14 volts, the regulator is defective. That can be replaced separately, but you may need to remove the generator from the engine to do that.

This is just a momentary test that lasts just long enough to see the results. If the charging voltage does jump up, don't raise engine speed. Without the regulator to limit system voltage, multiple computers can be damaged as well as any bulbs turned on can burn out.

If the voltage doesn't come up, the next best suspect is worn internal brushes, especially at the mileage you listed. To check them, do a continuity test between that test point screw, (blue arrow), and it's mate on the other side of the red arrow. The normal value is around four ohms. It's common to have a less-than-perfect connection, even with good brushes. While taking that reading, have a helper "irritate" the pulley a little by tugging on the drive belt.

Another problem we run into is those screw heads are usually badly corroded. You may need to scratch around with the test probes to get a good contact.

Worn brushes almost always start out as an intermittent failure-to-charge problem that gets progressively worse over weeks and months. I don't know if brushes are available separately. They are bolted to the voltage regulator, so you get new brushes with a new regulator.

Images (Click to make bigger)

Wednesday, April 16th, 2025 AT 5:36 PM