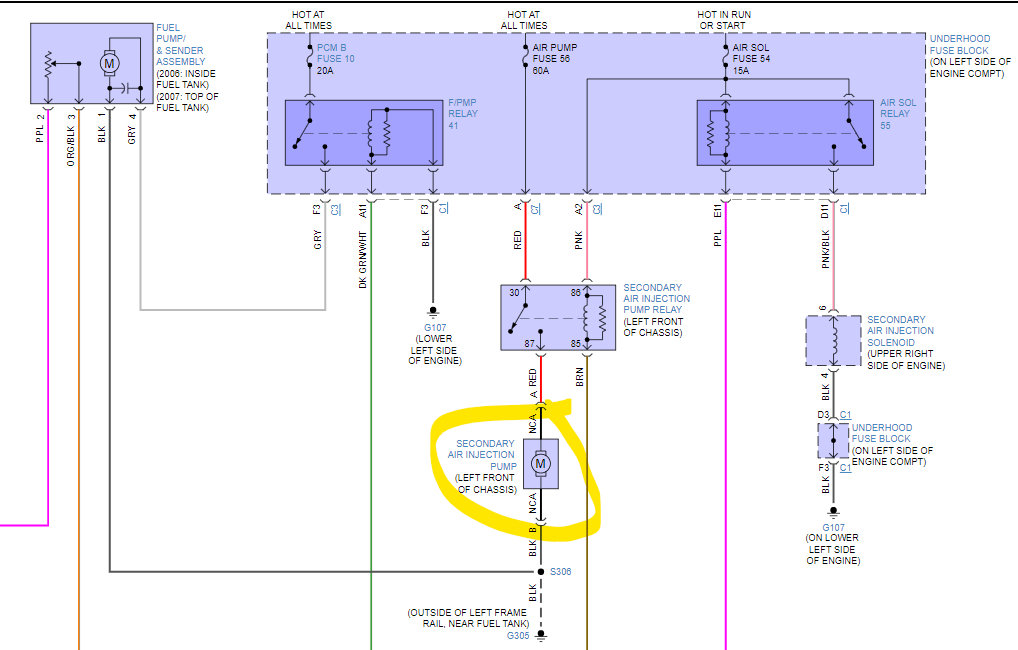

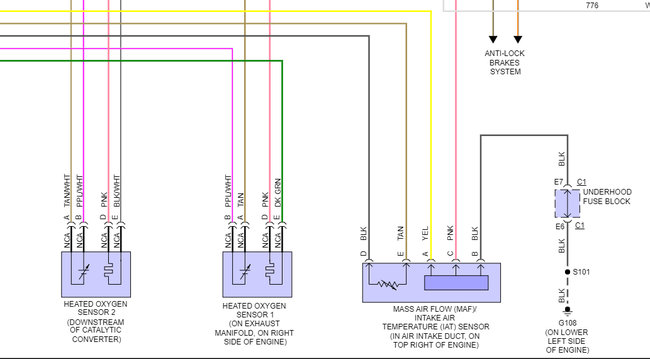

That front sensor looks strange, how long of a time base is that? It's average 0.55 volts and not making its upwards swing. If you raise the RPMs to 2,500, does it look the same?

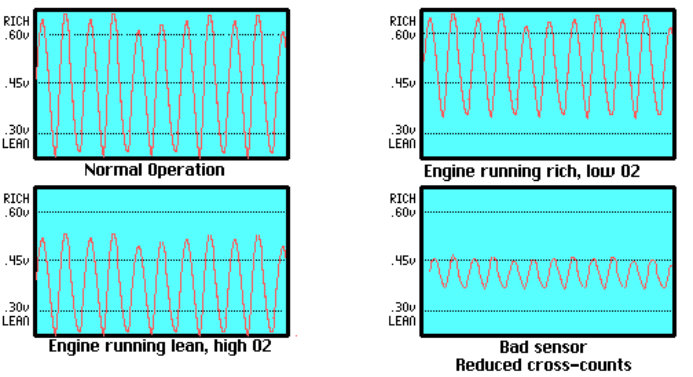

I can see why you're getting the p0171. See those downward spikes, those are all lean voltage signals. I can see its minimum/maximum is 0.19 to 0.72 but it's not swing high long enough. Below are some examples I found of what to expect from correctly functioning 02 sensor. In the first picture, the waveform below the "Normal Operation" is what you're seeing there on yours. And because your fuel trims are so high, your engine is starving for fuel or has excessive air getting into the exhaust and fooling the oxygen sensor into going rich. Because an Oxygen sensor only reads oxygen or a lack of it, not fuel.

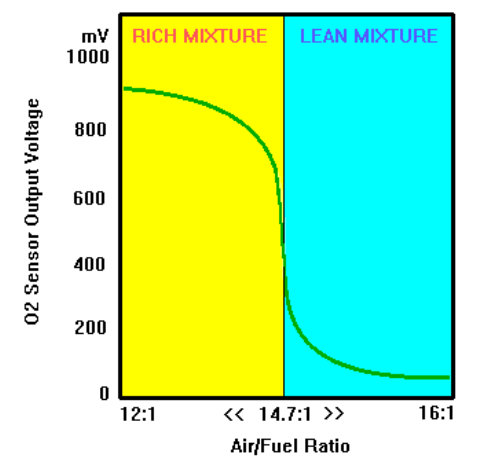

For example. A misfiring cylinder sends unburned fuel and oxygen into the exhaust, but because the Oxygen sensor only reads oxygen, it will actually enrich a mixture because of this. Thus, being fooled.

See what happens when you raise the throttle. And what type of brand sensor did you put in a couple years ago? That signal looks very biased. Is the wiring okay for it, it's not sitting on a hot exhaust pipe or something? Is the harness plug okay on it too?

Images (Click to make bigger)

Wednesday, December 22nd, 2021 AT 12:16 PM