Friday, September 20th, 2019 AT 3:12 PM

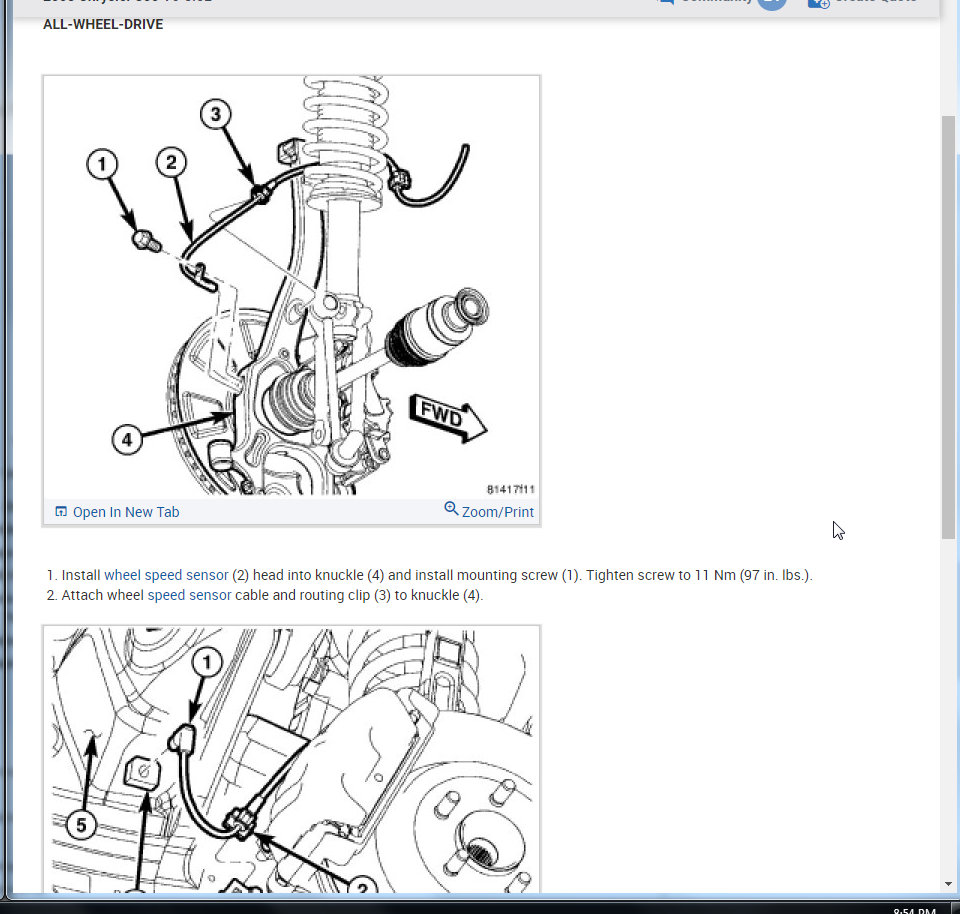

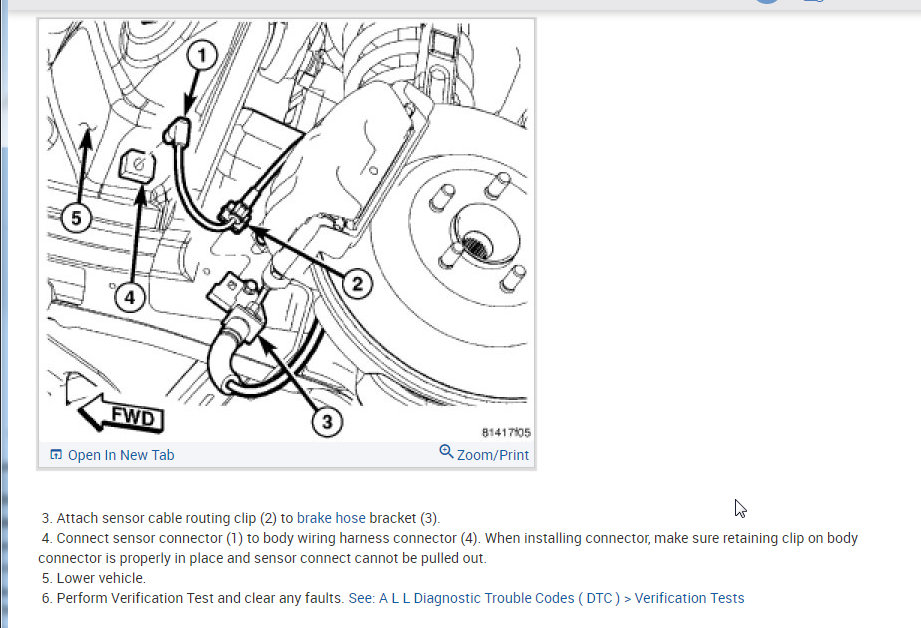

I checked all the brakes and the only thing I found wrong was a wheel sensor wiring broken so I need to replace it, right front please?