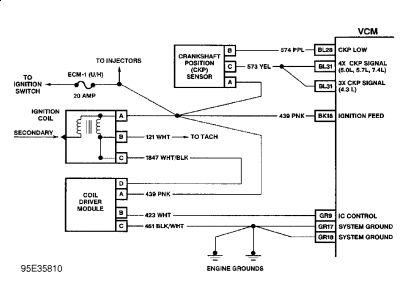

The long story is that we installed a new long block. As old school mechanics, we missed swapping the crank reluctor so we pulled the timing cover off and installed. It ran but rough idle. We bought the OBDII scanner to set timing, not it, pulled intake for leaks, pulled cover again to check timing chain, checked lift to make sure it didn't have a bumpy cam, put it together- no spark. Found a ground off, but still no spark. Accidently left the key on so thought maybe some component damage. Distributer was new on install, bought crank sensor. Chk'd coil, module, no codes. Got talked into a VCM, no spark. Have run the flow chart over and over, changed meters, testers, there is only.016 V AC on module terminal B. The IC circuit is grounded, VCM terminal #8 white wire, but if you unplug it, it is open. The ground is coming from the computer. Any ideas?

Tuesday, July 28th, 2009 AT 4:09 PM