If the canister has fuel in it too it needs to be replaced, next read the codes.

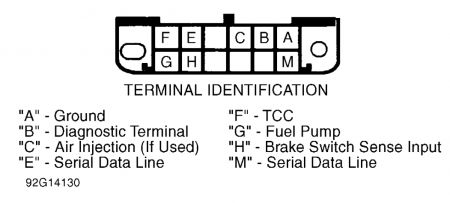

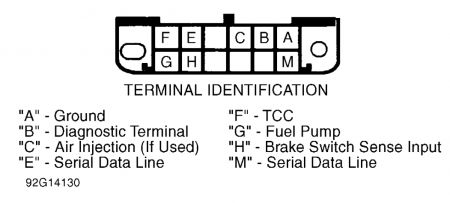

Cross these two terminals as shown, then turn the key on. Count the flashes, a 22 will flash as 2 flashes then a short pause, then 2 flashes, if more than one code is stored, the pause will be longer. The codes will display three times and end with 12. Write them down and post here. This connector is right under the middle of the dash...

RETRIEVING CODES (WITHOUT SCAN TOOL)

NOTE: The Assembly Line Data Link (ALDL) may also be referred to as the Data

Link Connector (DLC).

With key on and engine off, locate Assembly Line Data Link (ALDL) connector under dash, on

driver's side of vehicle. Connect a jumper wire between ALDL terminal "B" (test terminal) and

terminal "A" (ground terminal). See Fig. 2. This places control module in diagnostic mode.

1.

NOTE: Connecting terminals "A" and "B" of ALDL connector with engine

running will cause fuel injected vehicles to enter field service

mode. The MIL (SERVICE ENGINE SOON) light will not flash codes

if this is done.

Fig. 2:

In this mode, control module will display DTC 12 by flashing MIL (SERVICE ENGINE SOON)

light. DTC 12 is identified by MIL (SERVICE ENGINE SOON) light flashing once, followed

by a short pause, then 2 flashes in quick succession.

2.

Each DTC will be repeated 3 times. DTC 21 is identified by 2 flashes, a short pause followed by

one flash; DTC 53 is identified by 5 flashes, a short pause followed by 3 flashes. DTC's are

separated by slightly longer pauses.

3.

DTC's are displayed in numerical order. Each code is displayed 3 times. DTC's will continue to

repeat as long as ALDL test terminal is grounded. If DTC's are not flashed, or MIL (SERVICE

ENGINE SOON) light does not glow, self-diagnostics will not work. See CHART A-1 under

DIAGNOSTIC CHARTS.

5.

NOTE: DTC's will be recorded at various operating times. Some codes require

operation of sensor or switch for 5 seconds; others may require

operation for 5 minutes or longer at normal operating temperature, road

speed and load. Therefore, some codes may not set in a service bay

operational mode, but may require road testing vehicle in order to

duplicate condition under which code will set.

Friday, August 20th, 2010 AT 8:42 AM