Hi GaryHuff,

Thank you for the donation.

Here is a description of the fuel system and based on the open loop functions, you should be checking

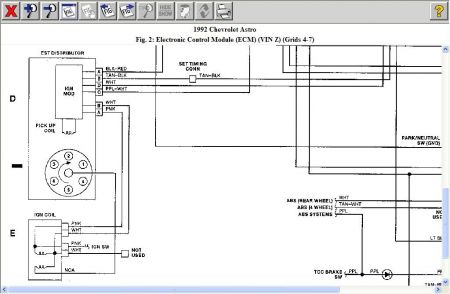

1. Engine Coolant Temperature.

2. Mass Air Flow sensor.

3. Crank or vcam sensor. If you have sparks, then these two are less likely to be the cause.

FUEL CONTROL

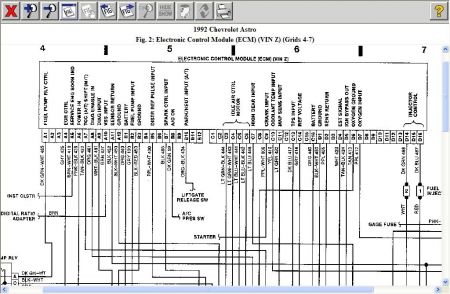

The ECM, using input signals, determines adjustments to the air/fuel mixture to provide the optimum ratio for proper combustion under all operating conditions. Fuel control systems can operate in the "open loop" or "closed loop" mode.

Open Loop

When engine is cold and engine speed is greater than 400 RPM, ECM operates in open loop mode. In open loop, ECM calculates air/fuel ratio based upon coolant temperature and MAP or MAF sensor readings. Engine remains in open loop operation until O2 sensor reaches operating temperature, coolant temperature reaches preset temperature and a specific period of time has elapsed after engine starts.

Closed Loop

When O2 sensor reaches operating temperature, coolant temperature reaches a preset temperature and a specific period of time has passed since engine start-up, ECM operates in closed loop. In closed loop, ECM controls air/fuel ratio based upon O2 sensor signals (in addition to other input parameters) to maintain as close to a 14.7:1 air/fuel ratio as possible. If O2 sensor cools off (due to excessive idling) or a fault occurs in the O2 sensor circuit, vehicle once again enters open loop mode.

On 4.3L engines, oxygen sensor is equipped with an internal heating element. This element enables system to reach "closed loop" sooner and maintain closed loop even during periods of extended idle.

There are 3 different types of injection system and since you mentioned 2 injectors, it should be this system.

Throttle Body Injection

Injectors are located in throttle body unit. All models except 2.5L use 220 Series dual injector throttle body. 2.5L models use 700 Series single injector throttle body. Battery voltage is supplied to injector when ignition is on. ECM energizes injector solenoid by providing a ground path through its internal circuitry. By regulating injector ground circuit, ECM controls injector "on" time (pulse width) to provide proper amount of fuel to engine.

Pressure regulator maintains pressure to injector at 9-13 psi (.6-.9 kg/cm 2 ). Excess fuel passes through pressure regulator and returns to fuel tank.

In the "run" mode, ECM uses tach (RPM) signal to determine when to pulse injector. Fuel injectors are pulsed once for each engine revolution; each spray provides 1/2 the fuel required for the combustion process. Thus, 2 injections of fuel (2 rotations of crankshaft) are mixed with incoming air to produce the fuel charge for each combustion cycle. On models equipped with dual injectors in the throttle body, injectors are pulsed alternately.

Fuel System Operating Modes

Internal ECM calibration controls fuel delivery during starting, clear flood mode, deceleration and heavy acceleration.

Starting

During engine starts, ECM delivers one injector pulse for each distributor reference pulse received (synchronized mode). Injector pulse width is based upon coolant temperature and throttle position. ECM determines air/fuel ratio when throttle position is less than 80 percent open. Engine starting air/fuel ratio ranges from 1.5:1 at -33 °F (-36 °C) to 14.7:1 at 201 °F (94 °C). At lower coolant temperatures, injector pulse width is wider (richer air/fuel mixture ratio). When coolant temperature is high, injector pulse width becomes narrower (leaner air/fuel ratio).

Clear Flood

If engine is flooded, driver must depress accelerator pedal to Wide Open Throttle (WOT) position. At this position, ECM adjusts injector pulse width equal to an air/fuel ratio of 20:1. This air/fuel ratio is maintained as long as throttle remains in wide open position and engine speed is less than 600 RPM. If throttle position becomes less than 80 percent open and/or engine speed exceeds 600 RPM, ECM changes injector pulse width to that used during engine starting (based upon coolant temperature and manifold vacuum).

Heavy Acceleration

ECM provides fuel enrichment during heavy acceleration. Sudden opening of throttle valve causes rapid increase in MAP signal. Pulse width is directly related to MAP, throttle position and coolant temperature. Higher MAP and wider throttle angles give wider injector pulse width (richer mixture). During enrichment, injector pulses are not in proportion to distributor reference signals (non- synchronized). Any reduction in throttle angle cancels fuel enrichment.

Deceleration

During normal deceleration, fuel output is reduced. This reduction in available fuel serves to remove residual fuel from intake manifold. During sudden deceleration, when MAP, throttle position and engine speed are reduced to preset levels, fuel flow is cut off completely. This deceleration fuel cut-off overrides normal deceleration mode. During either deceleration mode, injector pulses are not in proportion to distributor reference signals.

Battery Voltage Correction

ECM compensates for low battery voltage by increasing injector pulse width and increasing idle RPM. ECM is able to perform these commands because of a built- in memory/learning function.

Fuel Cut-Off

When ignition is turned off, injectors are de-energized to prevent dieseling. Injectors are not energized if RPM reference pulses are not received by the ECM, even with ignition on. This prevents flooding before starting. Fuel cut-off also occurs at high engine RPM to prevent internal damage to engine. Some models may also cut off fuel injector signals during periods of sudden, closed throttle deceleration (when fuel is not needed).

Monday, January 26th, 2009 AT 2:12 PM