If you know about PLCs, you know much more than the average person. That will make this easier to explain.

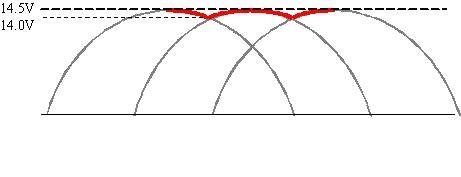

The alternator develops three-phase output, and once rectified, the pulses of output voltage are pretty smooth, but it's the battery that really smooths out that "ripple" voltage. In my sad drawing, the ripple voltage is 0.5 volt, the difference between the 14.0 and 14.5 volts. As the battery ages, the lead flakes off the plates, and the ability to smooth that ripple voltage goes away, even though that battery can still crank the engine just fine. Now the question is what voltage is the regulator going to see and respond to? Suppose the target charging voltage is 14.4 volts. If the regulator sees the 14.0 volts on its sensing wire, it's going to try to bump up alternator output to get to 14.4 volts, but in so doing, at times the 14.5 volts might go a little higher before the regulator detects that and corrects for it. You'll see that as the head light brightness flickering. The same thing happens when people disconnect a battery cable thinking that's a way to tell if the alternator is working! (Don't ever do that).

This has been a real big problem with GM vehicles after they redesigned their generators for the '87 model year. They use the same common switching circuit that turns field current on and off about 400 times per second, but for some reason their generators develop huge harmful voltage spikes that can damage the internal diodes and regulator, and interfere with computer sensor signals. They even use three zener diodes of the six to try to short out those spikes. Once again it's the battery that dampens and absorbs those spikes, and once again, they lose their ability to do that as they age. It is real common for people to go through four to six replacement generators in the life of the vehicle. To reduce that number of repeat failures, always replace the battery at the same time, unless it is less than about two years old. The old battery will work fine in an '86 or older model.

I wasn't clear on the tests you did when you disconnected the battery cables. Did you have just one off at a time? If so, I suspect your confusion came from the unexpected voltage when the ignition switch was off. In fact, before the mid '90s there was still the "IOD", (ignition off-draw) circuit that maintained the memories in some of the computers. That was allowed to be up to 35 milliamps for most car models. By the mid to late '90s, a lot of cars have an Engine Computer that needs up to 20 minutes to go to "sleep mode" after the ignition switch is turned off. During that 20 minutes they can draw up to three amps. This makes the old conventional testing method for a battery drain obsolete. I can describe the procedure, if you need it, on how to do the testing as before, with an amp meter in series with one battery cable, but you need to short the meter with a jumper wire for that 20 minutes and any time you change ranges on the meter. Any momentary break in the circuit wakes the computer up again and restarts the 20-minute timer.

It appears you found part of the problem with the old battery, but there is still something going on with the cables causing an intermittent problem. The goal now is to get it to act up, then be careful to not disturb anything that could cause the electrical system to come back to life. We need to get under the hood with the voltmeter with the problem occurring so there is something to diagnose. A test light works better for this type of problem because it requires current flow through it to work. All you need is a tiny carbon track for the voltmeter to pick that up and incorrectly say there's a good circuit there.

When the problem is occurring, turn on the head lights so current is trying to flow. That will make the following procedure show up the bad connection more effectively. Start with the negative meter probe, or test light's ground clip, right on the battery's negative post, and the other probe on the positive post. You'll find 12.6 volts if the battery is good and fully-charged. Now move the negative probe from the post to that cable clamp. You should find the same voltage. Move the positive probe from that post to that cable clamp, and expect to see the same voltage. If the voltage drops when you move a probe from one point to the next, that is the point of the bad connection.

Move the negative probe to a paint-free point on the body sheet metal or exposed bolt head. This type of problem is caused by a loose or rusted connection of the smaller negative battery wire at the body perhaps two or three percent of the time.

Now move the positive probe by following the smaller battery positive wire to the under-hood fuse box, and put the probe on the wire's terminal where you're likely to still find 12.6 volts. Finally, move that probe to the stud that terminal is bolted to. This is where you're going to drop to near 0 volts most of the time. Clean that terminal, then be sure that nut is tight. This one connection has been the cause of most intermittent dead electrical systems on every brand of car.

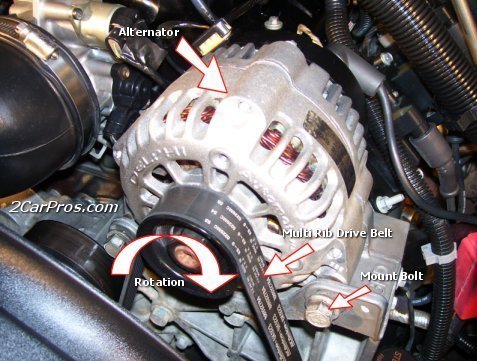

The large positive battery cable is only for the starter motor. It's the smaller one that puts the battery in the circuit to smooth ripple voltage, so a poor connection there is like removing the battery while the engine is running. The result then would be the flickering lights. The regulator is seeing the changing ripple voltage and is trying to keep up with it. By the time is responds appropriately, the voltage has already changed again. The regulator will have a nervous breakdown trying to maintain system voltage.

Image (Click to make bigger)

Tuesday, May 7th, 2019 AT 5:10 PM