Hi guys. Please allow me to add a few observations in hopes of preventing property damage to the people in your community. If you can't afford a ten-dollar pre-manufactured brake line, you can't afford to fill the gas tank, so problem solved. Aside from that uncalled for sarcasm, GM has already done what you're trying to do, so the fact you have no brakes means the car has at least two separate problems. In fact, if there are already a number of warning lights being ignored, this current problem may, in fact, be the second problem. It's likely the first brake system problem occurred some time ago.

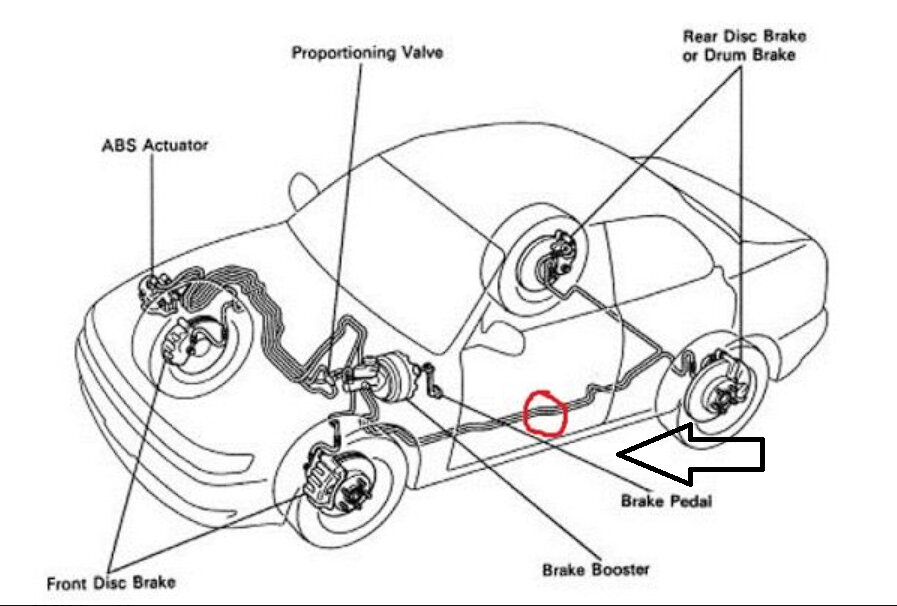

To get more specific, GM has used an unusual master cylinder design for many years on their front-wheel-drive cars. Since the 1960s, a dual brake system has been required on all cars. Both systems always develop equal brake fluid pressures, except when there's a leak in one system, then a valve moves and turns on the red "Brake" warning light. On those older vehicles, up to three different switches could turn that waring light on, each with different causes. One system worked the front brakes and one worked the rear brakes. If a leak developed in the front system, you lost roughly 70 percent of your braking power.

When the smaller front-wheel-drive cars showed up with the '78 Horizon and Omni, the weight distribution was such that the front brakes did 80 percent of the stopping. With a loss of the front brakes, the rear wheels would lock up, tires would skid and have no traction, and they'd find you in the next county. To address that, the "split-diagonal" system was developed. That pairs one front brake with the opposite rear brake on the same circuit. Regardless which system developed a leak, you still had 50 percent of stopping power.

Just one working front brake is normally extremely dangerous to the point the car simply can't be driven. Applying that one brake will tear the steering wheel out of your hand with way more than enough force to break wrists. (I tried driving a '66 Buick Wildcat like that). The way the manufacturers overcame that was to heavily modify a number of key alignment angles. The working brake develops a secondary force that pulls the other way to offset the brake pull. Chrysler has that so well perfected that the only way to know there is a problem is the red warning light turns on. The brake pedal feels normal, and there's no pull to either side. On other car brands, the most you might see is a very slight wiggle in the steering wheel as the brakes are applied. That wiggle is too small for most people to notice, so again, all you have for symptoms is the warning light. If you ignore that one, you're already driving with just half the brakes, then it's just a matter of time before a second problem results in no brakes and a sinking brake pedal.

The unusual feature in your master cylinder is a special valve that prevents the loss of fluid you're seeing. Think of a small teeter totter between the two ports where the steel lines are attached. That valve remains centered as long as both systems develop equal pressures. That can only occur when there's no leaks. Once a leak develops, the unequal pressures cause that valve to shift position. In doing so, the port with the leak gets blocked off, or closed, so no brake fluid will be lost. The only down-side to this is it can make finding the leak a little more tedious because there's little wetness to lead you to it.

There's a second way that valve can be tripped, and it relates to your lack of knowledge about brake bleeding. You tried bleeding the system to remove air that had no way of getting into the system in the first place. There was no air to remove, but with common methods, we open one bleeder screw at a time, then many competent do-it-yourselfers think they need to have a helper push the brake pedal. It is possible to get away with that if the pedal is never pushed more than about a quarter way to the floor, but most of the time the helper runs the pedal down as far as it will go. That can instantly cause multiple new problems, but for this story, that will trip the valve in the master cylinder. From that moment, no brake fluid will flow from one front brake and the opposite rear one. A lot of people even replace the master cylinder, then cause the same problem with that one when they try to bleed the system.

The next issue occurs on any car brand, to any master cylinder more than about a year old. Crud and corrosion builds up in the lower halves of the bores where the pistons don't normally travel, meaning the brake pedal never goes more than halfway to the floor. Once a leak develops, the pedal gets run down too far due to the surprise. The rubber lip seals run over that corrosion and get ripped. That results, at first, in a slowly-sinking brake pedal, and that commonly takes two or three days to show up. Given that valve in the master cylinder, that internal damage should not occur. The fact the brake pedal is going down too far tells us the master cylinder is already damaged, and / or there is a second leak that has been ignored or unknown. The second clue is the brake fluid you see dumping onto the ground. If that was the only leak, the valve would have blocked fluid flow to it. That valve is not spring-loaded and will not reset on its own and it will not shift the other way.

Let me interject a note here. The only way I have ever found to reset that valve is once all the leaks are repaired, loosen the cap on the reservoir, go to one of the bleeder screws that isn't flowing any fluid, and give it a very short, quick burst of compressed air. You don't want to force air in too far because it will just have to be bled back out. Rather, a quick karate chop to the air nozzle is more than enough, then just let it gravity-bleed for a minute for that air to come back out. Once fluid flows from all the bleeder screws, be careful to not push the brake pedal very far.

By the way, another way this valve can trip is after performing a normal, typical brake service. The pistons in the calipers have to be pushed in to make room for the new, thicker pads. Once everything is reassembled, the pedal has to be pumped multiple times to run those pistons back out to adjust them. Typically one piston has a little less resistance and moves first. Once in adjustment, pressure will start to build each time the pedal is pressed. By building pressure in just one side, that valve responds to what it thinks is a leak. It shifts and blocks that port. The result CAN be one front brake wears out and starts grinding metal-on-metal too early, and the pads on the other side look like brand new. Only one front brake has been working for thousands of miles and the driver never noticed except for the warning light. Even to this day, a lot of mechanics aren't aware of the cause or the solution to this.

For the double flaring tool, in my city we have over a dozen parts stores and they all work the same way. They make you buy the tool, then you get a full refund when you return it. If you choose to keep a tool, you still return it, then they give or order you a brand new one. There are some really nice tools on the market now that are pretty expensive, but the old, standard tool set typically costs less than $45.00.

I'm also in snow. In fact, in my state, they throw a pound of salt on an ounce of snow, so I'm very familiar with rust. As such, I know there is no way you're going to solve this leak in any way other than to replace the steel line all the way from each end. That actually works in your favor, and it's likely you won't need the flaring tool. If your car has anti-lock brakes, follow the leaking line up to the hydraulic controller and remove it there. If you don't have anti-lock brakes, follow the line to one of the two lower ports on the master cylinder. Take that section of old line to the parts store to match it up. The soft brass fitting should be a standard, metric size, but if it's larger in diameter than the fitting on the new line, they have all kinds of adapter fittings to set you up. Measure the length you need to reach all the way to the fitting at the rear. That will not be all the way to the wheel because there has to be a flexible rubber hose first.

Replacement line comes in a number of standard lengths up to three or more feet. They'll have brass unions to connect two lines. Be sure to test-fit them so you don't end up with a metric fitting and a standard union.

I'd avoid, at all cost, removing the old steel line in the area of the leak. The line for the other side is going to be just as rusty, and any movement can be enough to crack it and cause that one to leak. Instead, use nylon tie straps to hold the new line to the group of old ones. GM likes to feed their lines through places that can only be accessed while the car is going together on the assembly line. It is not necessary to follow the same path. It's okay to go around sheet metal brackets, but avoid running it too close to hot exhaust parts, bend it to prevent it from rubbing or vibrating against sharp metal brackets. You can also cut a slit in a short piece of rubber hose to isolate the steel line from something it might rub on.

For some time, a new type of replacement line with an anodized coating has been available. That coating is meant to prevent rust, but look into the added cost. It's likely a standard line is going to outlast the car.

Another tip. When you have as much rust as I do, there's an almost certainty the bleeder screw on the rear wheel cylinder is going to be rusted tight. Replacement wheel cylinder can be as little as ten bucks, but replacing one means a lot more time. I'm not interested in more time when I have to do my repairs while sitting in a snow-covered driveway. Instead, leave that rear connection of the new line loose. Fill the reservoir with new, clean brake fluid, then wait for it to gravity-bleed. Leave the reservoir cover loose so no vacuum builds up as the fluid runs down. If necessary, it's okay to "irritate" the brake pedal a little, by hand, to get the flow started. It can take a good ten minutes for the fluid to show up at the end of the new line. It may help to leave it totally disconnected too. Allow the fluid to keep dripping while you attach the line to the rubber flex hose. That lets the last of the air to work its way out. Doing it this way can leave it with a few tiny air bubbles still in there, but you will never know it. It takes a real lot more air in the system to have a low or spongy pedal.

When you're done with this line and ready for a test drive, don't panic if the warning light turns back on. If the brake pedal feels normal, it means there is that other problem that went ignored previously. You may need to use the compressed air to reset the valve, then wait to see where wetness develops to find that leak. We'll address that when the time comes. It's also possible there is no second problem. Perhaps just the valve / light needs to be reset.

If you also see a yellow "ABS" warning light, we can address that too. First, it will turn on any time the red light is on. The anti-lock Brake Computer sees the red light is on, but it doesn't know why. (It can be that valve has tripped, the fluid level in the reservoir is low, or the parking brake isn't fully released). All the computer knows is it might not be able to prevent a skid properly, so it shuts itself down, then turns on the yellow light to let you know. To say that a different way, there's a good chance the yellow warning light will turn off when the red one turns off.

GM has another very common problem with front wheel bearings that lead to only the yellow warning light turning on. We can help with that too if it becomes necessary. As for all the other warning lights you mentioned, we encourage you to start new questions for each one. They can have something in common, but by addressing them separately, your questions get categorized by model and by topic for the benefit of others researching similar problems. Also, unlike on other forums where anyone can chime in to confuse the issue, here it becomes a private conversation, (except when I stick my nose in here), and as such, by adding on new topics, they won't be seen by the other experts who, believe it or not, might be more qualified to provide the best answer. Starting a new question has a better chance of getting you the best help.

With that, I'll wait to learn how this gets solved. Let me know if you need more of my wondrous wisdom.

Friday, January 17th, 2025 AT 10:47 PM