Saturday, October 9th, 2010 AT 9:53 PM

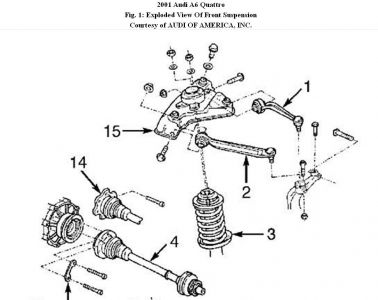

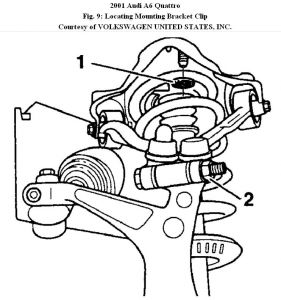

I am trying to replace the right side axle assembly and I am having no luck trying to remove the top pivot point control bolt ( this is where the to control arms pivot and connect to the arm that extends down and holds the wheel bearing and brake) I have removed the nut on the end and the manuel doesnt give any special instructions on removing this bolt. I have used a numatic chisel and tried to push it out, I can turn the bolt and it will not screw out. I have also tried prying it out and no luck. How do I get this bolt out?