Hello, I'm Danny.

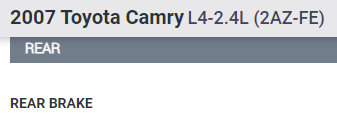

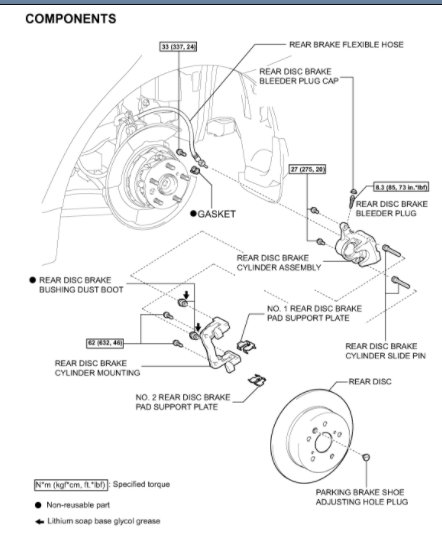

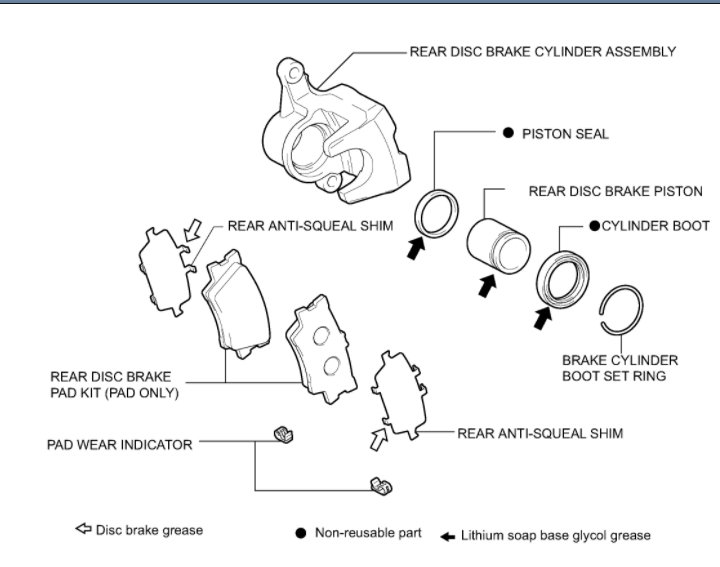

The sound might be metal on metal noise from the pads being worn out contacting the brake rotor. Here is a tutorial on how to remove and replace rear brake pads and rotors:

https://www.2carpros.com/articles/how-to-replace-rear-brake-pads-and-rotors

Here is a youtube video from our site on how to compress the rear caliper piston when performing a rear brake job:

https://youtu.be/j8YwfSKEzZo

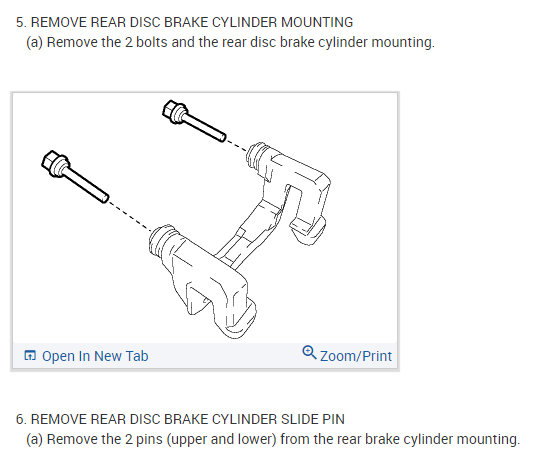

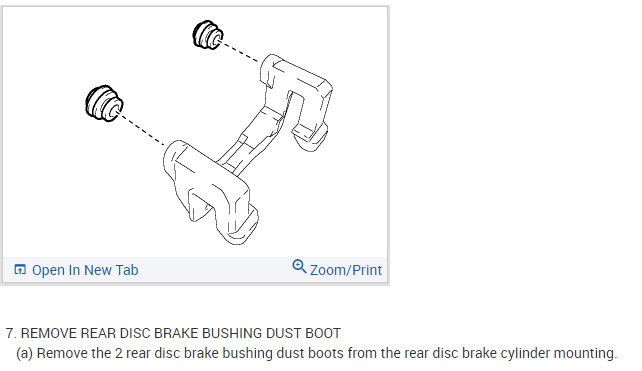

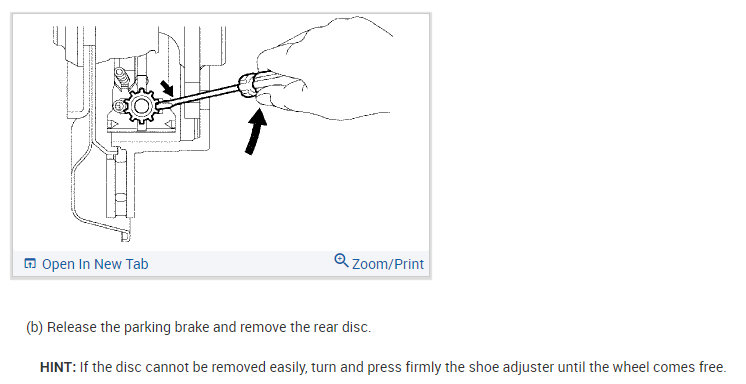

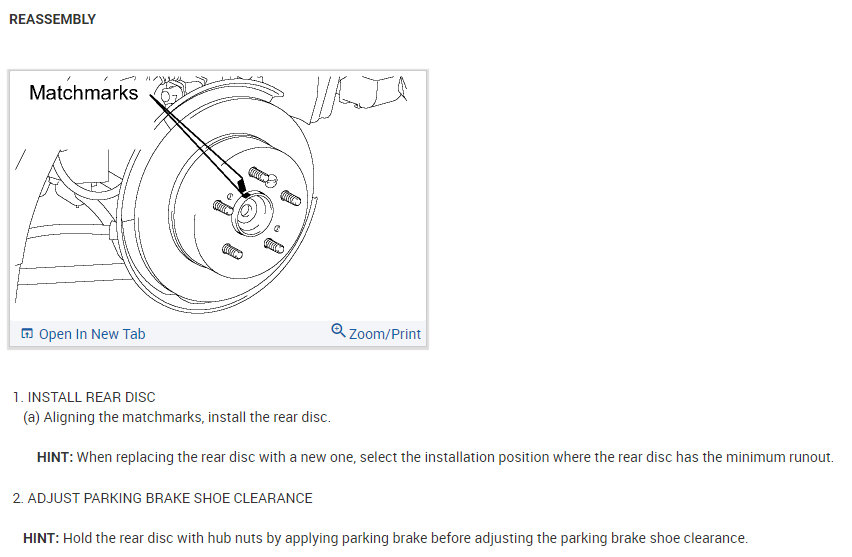

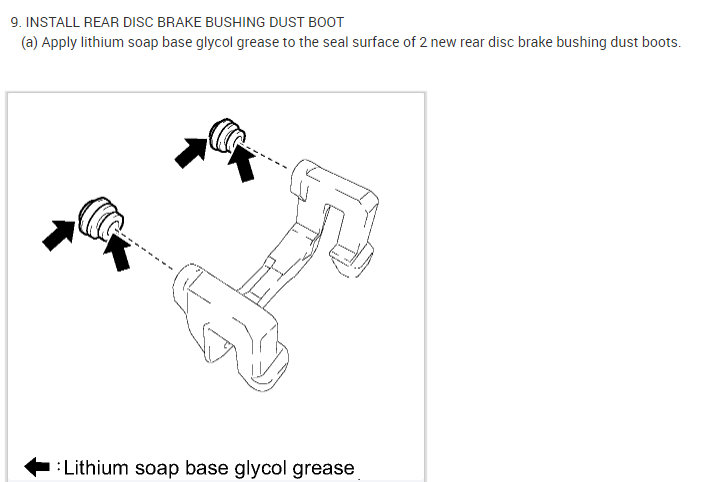

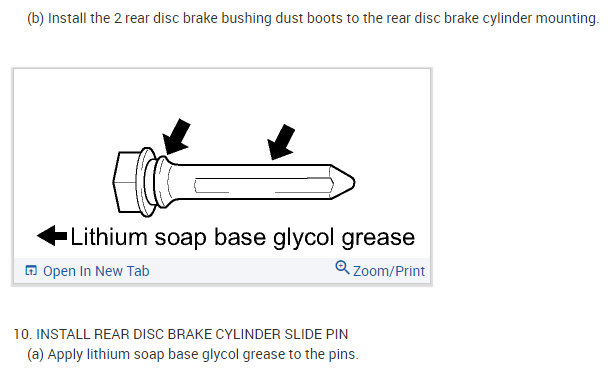

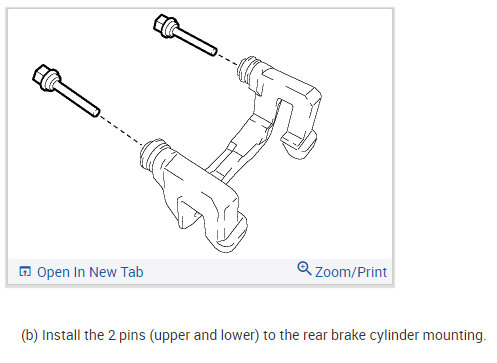

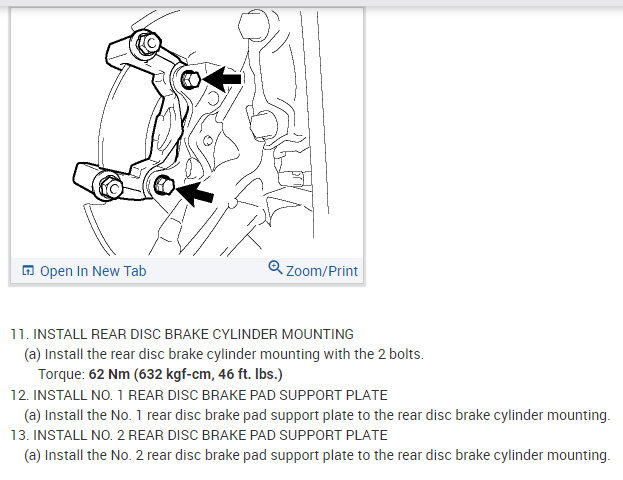

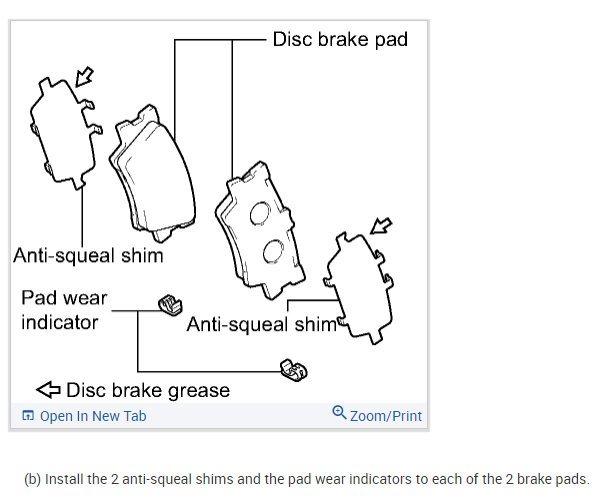

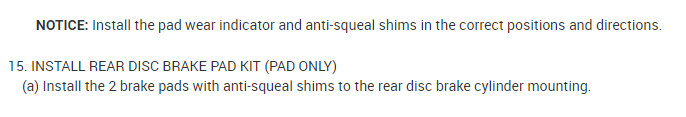

I've attached picture steps below on how to replace the brake pads and rotors on your car. Hope this helps and thanks for using 2CarPros.

Images (Click to make bigger)

Friday, March 5th, 2021 AT 10:11 AM