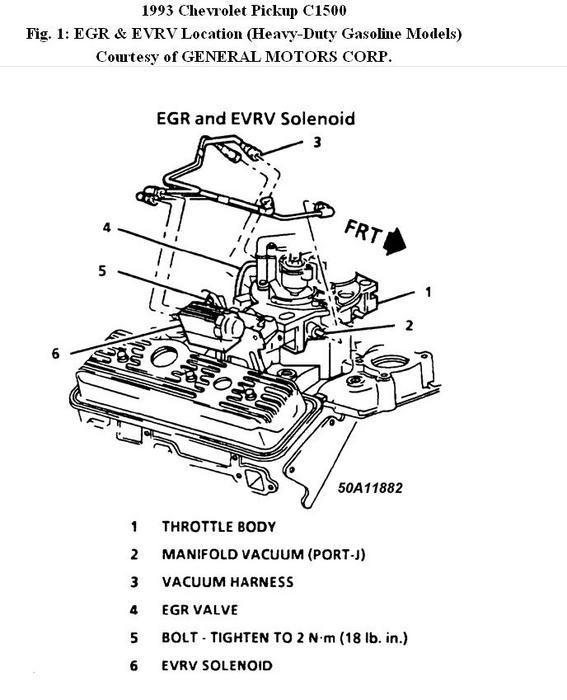

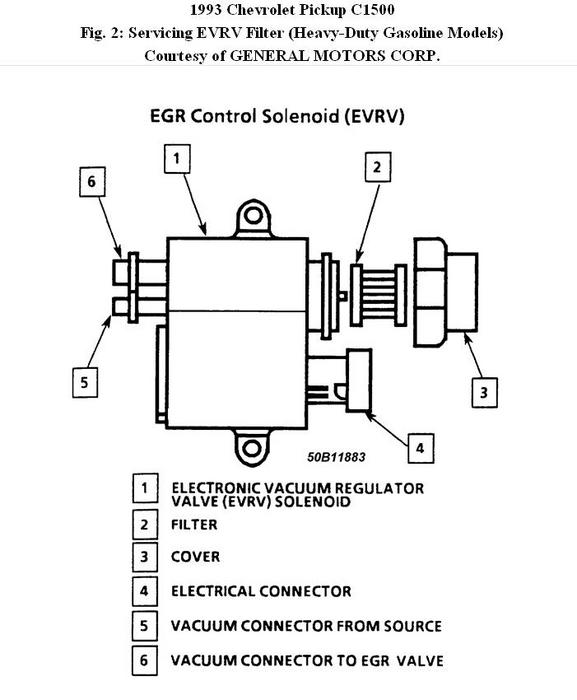

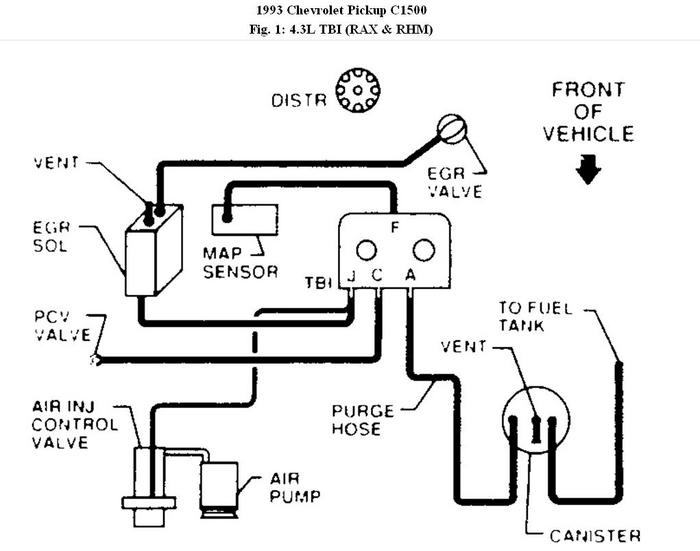

Symptoms indicates a likely fault with the EGR system as the operating vehicle speed is within engine rpm range of between 2000 to 3000 rpm and disabling the EGR seems to resolve the problem, I would suggst starting from there.

Try cleaning the EGR solenoids and clearing the ports of clogging and retest. Carb cleaner is a reliable solvent for cleaning clogged ports, with the aid of a stiff wire.

If the SES light indicates intermittently, retrieving the trouble code would help to diagnose the problem.

RETRIEVING CODES (NON-SCAN)

NOTE:

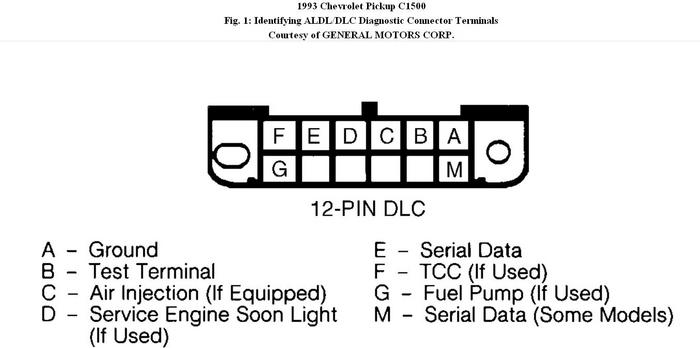

The Assembly Line Data Link (ALDL) connector may also be referred to as the Data Link Connector (DLC) in flow charts. This is the same connector.

1. Turn ignition on with engine off. Malfunction Indicator Light (MIL) should glow. Locate Data Link Connector (DLC), attached to ECM wiring harness. Most DLCs are located under dash on driver's side of vehicle. Turn ignition on. Insert jumper wire from terminal "B" (diagnostic test terminal) to terminal "A" (ground) of DLC. See Fig. 1.

NOTE:

Inserting jumper wire into test and ground terminals of DLC with engine running will cause fuel-injected vehicles to enter field service mode and codes will not flash.

2. Malfunction Indicator Light (MIL) should flash codes. Each code is flashed 3 times. If codes DO NOT flash, perform DIAGNOSTIC CIRCUIT CHECK (GASOLINE). To exit diagnostic mode, turn ignition off and remove jumper wire from DLC.

READING TROUBLE CODES

NOTE:

Trouble codes retrieved from ECM/PCM/VCM may be related to either engine or transmission.

The ECM stores component failure information under a related trouble code which can be recalled for diagnosis and repair. Read trouble codes by counting Malfunction Indicator Light (MIL) flashes or with diagnostic scan tester connected to the Data Link Connector (DLC). The tester is faster, and capable of reading information which would require testing individual ECM and sensor/solenoid connector terminals with a digital voltmeter.

NOTE:

When using a scan tester, there is a time delay between serial data updates. For instantaneous response, a digital voltmeter must be used.

If scan tester is not available, MIL flashes can be read by grounding DLC terminal with ignition on and engine off. For example, FLASH, FLASH, pause, FLASH, longer pause, indicates Code 21. The first series of flashes are the first digit of trouble code. The second series of flashes are the second digit of trouble code. Trouble codes are displayed starting with the lowest code. Each code is displayed 3 times and will continue as long as DLC is grounded.

NOTE:

Trouble codes will be recorded at various operating times. Some codes require sensor or switch operation for 5 seconds and others may require longer under certain conditions. Some codes may not set in a service bay operational mode.

https://www.2carpros.com/articles/buick-cadillac-chevy-gmc-oldsmobile-pontiac-gm-1983-1995-obd1-code-definitions-and-retrieval-method

The above link should be helpful.

Let me know what you find.

Images (Click to make bigger)

Monday, February 7th, 2011 AT 5:03 AM