Engine oil is used to cool and lubricate bearing and machined surfaces. Without oil pressure an engine will experience extreme internal engine damage due to heat caused by friction. All engines run on a pre-set pressure that cannot be adjusted. This pressure will vary depending on engine speed, temperature and weight oil. As a rule of thumb, the engine oil pressure gauge shouldn't drop below 1/4 or exceed 3/4 pressure of the gauge.

Lets' Jump In!

To verify the engine oil pressure is low, start the engine (cold) and observe

the gauge or light.

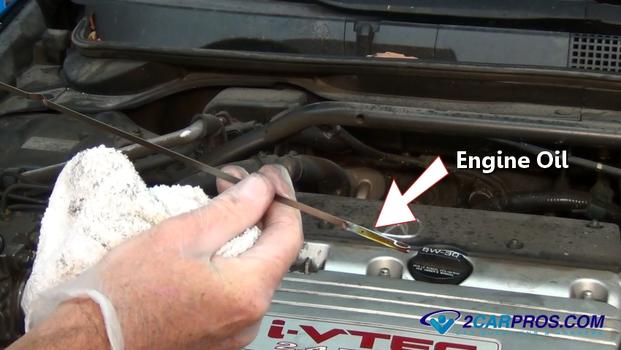

Using the engine oil dip stick, check the oil level of the engine and ensure

a proper level.

The oil pressure switch is designed to send feedback data to the gauge or computer.

These switches can go bad causing the gauge or light to show a false reading, remove

the switch and insert a manual gauge to the engine and restart the engine. The gauge

should read between 25 and 45 pounds.

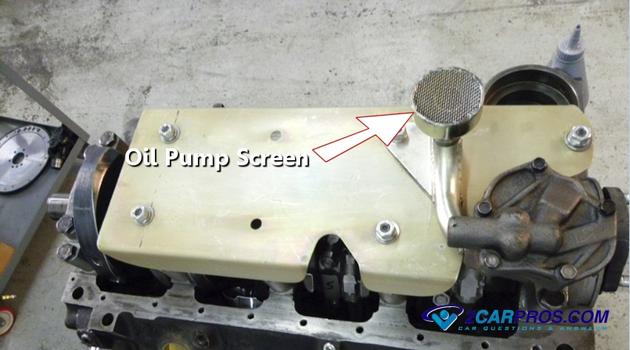

The oil pump uses a screen to keep out impurities before entering the pump. If

this screen becomes plugged with sludge due to lack of maintenance, the pump will

scavenge causing low pressure. (Engine oil pan removed while turned over.)

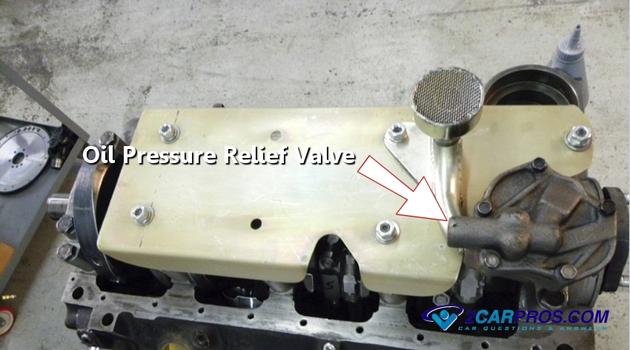

The oil pump is also designed with an oil pressure relief valve and spring which

regulates pressure. If this valve becomes faulty caused by a broken pressure spring

the pump will have low oil pressure.

An engine bearing is designed to support the crankshaft and other various engine

parts while in motion. When these bearings wear, they can allow more oil to escape

causing low oil pressure, this is a sign the engine has worn out and replacement

or rebuilding is needed.

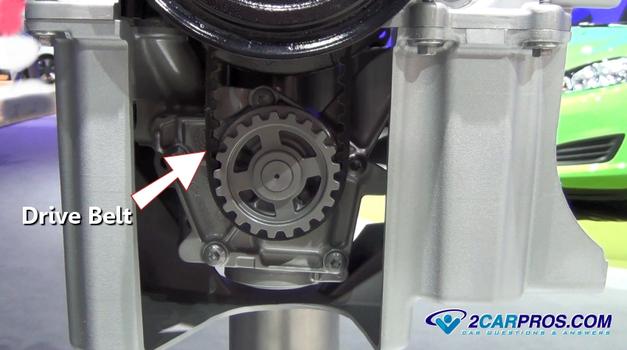

If the engine has no oil pressure, suspect the oil pump drive, some manufactures

use a belt to drive the pump which are prone to failure.

Questions?

Our certified technicians are ready to answer low oil pressure questions for free. We hope you saved money and learned from this guide. We are creating a full set of car repair guides. Please subscribe to our 2CarPros YouTube channel and check back often for new videos which are uploaded regularly.