The problem:

Rear brakes were dragging after application of pedal for about 2 seconds. As pressure appeared to bleed off, normal operation of car, no dragging. Pushing on pedal would re-create. Tapping on pedal didn't seem to be so pronounced.

No codes from ABS unit when shorting pins 4 & 5 on ABS connector and checking dash lamp with Key On.

ABS passes self test at startup, remains on about 4 seconds after car starts and then goes out.

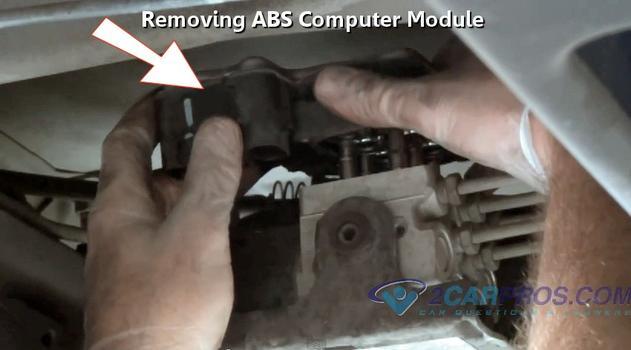

Presumed this problem is isolated to the Teves II ATE Solenoid Control Valve Body. Removed unit from car and removed cover, found lower center valve in the body severely discolored. Almost black, like it was burning. Checked resistance of all 6 solenoids and all measure 3-8 ohms per the shop diagnosis section. No short to ground condition found.

Replaced Solenoid Control Valve body with a unit from another used car, (140K) and now the front brakes are exhibiting the exact same problem, but rears are OK! (I checked all 6 solenoids in this unit, and color and resistance measurements were again within spec.)

To me, this sounds like the dump (N/C) solenoid/valves are stuck closed and not opening properly at the end of the normal braking operation.

I can test the solenoids for shorted (to case) and open conditions, but I cannot test the solenoids for proper operation.

I do not know if they take a +5V signal or a +12V signal to activate. And I don't want to burn them out with too much voltage. And I can't seem to find my +5V power supply at the moment.

I would also like to know if there are any rebuilding services that can clean/test/replace these ATE solenoids. If I could get known good/clean solenoids, I could replace them easily enough. The plastic circuit board is similar to things that I have soldered on before. Easy does it!

Other info:

Rear flexible hose has been replaced.

Accumulator pressure and pump still operate just fine.

All calipers have been rebuilt and assembled with brake lube.

System has been bled multiple times with clean fluid.

I just can't figure (or find a proper Theory of Op's manual that would explain.) How anything in the actual master cylinder unit would restrict back flow of fluids. Everything points to the control valves that I read. It is just that NONE of the diagnosis charts outline how to test these beyond simple ohmmeter checks. No listed symptoms match the problem!

The fact that I have changed the symptoms (rear to front) by changing the control valve makes me believe I am on the right track. However, the next time I do this job, I want it to be the last! (On this car anyway!) It is a real bugger to do. Not to mention VERY messy!

Hope you can help with some info on suppliers/rebuilders or a way to test these with voltage and an air supply etc!

Thanks,

Steve

SPONSORED LINKS

Monday, October 25th, 2010 AT 1:36 AM