Hello -

I have attached a TSB that shows the proper procedure on how to remove the plug without removing the heads.

SPARK PLUG REMOVAL INSTRUCTIONS - 4.6L 3V/5.4L 3V/6.8L 3V

TECHNICAL SERVICE BULLETIN

Reference Number(s): 08-7-6, Date of Issue: April 18, 2008

FORD: 2005-2008 Mustang; 2004-2008 F-150; 2005-2008 Expedition, F-Super Duty; 2006-2008 Explorer, F-53 Motorhome Chassis; 2007-2008 Explorer Sport Trac

LINCOLN: 2005-2008 Navigator; 2006-2008 Mark LT

MERCURY: 2006-2008 Mountaineer

Superceded Bulletin(s): 08-1-9, Date of Issue: January 21, 2008

Related Ref Number(s): 06-15-2, 06-5-9, 08-1-9, 08-7-6

ARTICLE BEGINNING

ISSUE

NOTE: This article supersedes TSB 08-1-9 to update Vehicle Applications, Service Procedure and Part List.

Some 2004-2008 F-150, 2006-2008 Mark LT, 2005-2008 F-Super Duty, Expedition, and Navigator, with 5.4L 3-V engine; 2005-2008 Mustang, 2006-2008 Explorer, Mountaineer, and 2007-2008 Explorer Sport Trac with 4.6L 3-V engine; 2005-2008 F-Super Duty, 2006-2008 and F-Stripped Chassis, with 6.8L 3-V engine may experience difficulty with spark plug removal. This may cause damage to the spark plug and leave part of the spark plug in the cylinder head. Affected engine build dates are as follows: 5.4L 3-V and 6.8L 3-V before 10/9/07, 4.6L 3-V before 11/30/07.

ACTION

Refer to the following Service Procedure for techniques to remove the spark plugs and extract broken spark plugs.

SERVICE PROCEDURE

The engine build date can be read on the left hand cam cover information sticker.

To remove spark plugs without damage, it is necessary to adhere exactly to this procedure before removal is attempted.

CAUTION: DO NOT REMOVE PLUGS WHEN THE ENGINE IS WARM OR HOT. THE ENGINE MUST BE AT ROOM TEMPERATURE WHEN PERFORMING SPARK PLUG SERVICE. REMOVING THE SPARK PLUGS FROM A WARM/HOT ENGINE INCREASES THE CHANCE THE THREADS COULD BE DAMAGED.

SPARK PLUG REMOVAL PROCEDURE

1. Remove the coil-on-plug assemblies and thoroughly blow out the spark plug wells and surrounding valve cover area with compressed air.

2. Back out the spark plugs no more than 1/8 to 1/4 of a turn. Using Motorcraft  Carburetor Tune-Up Cleaner, fill the spark plug well just above where the jamb nut hex sits (1/2 - 3/4 teaspoon). A minimum period of 15 minutes of soak time is required. The cleaner will wick down to the ground electrode shield and soften the carbon deposits in this time. DO NOT WORK the spark plug back and forth at this point.

NOTE: COMPLETELY REVIEW THE PRODUCT LABEL FOR THE MOTORCRAFT Â CARBURETOR TUNE-UP CLEANER PRODUCT- USE AT ROOM TEMPERATURE AND SHAKE WELL.

CAUTION: EXCESSIVE MOTORCRAFT Â CARBURETOR TUNE-UP CLEANER, OR REPEATING THE PROCESS SEVERAL TIMES WITH TOO MUCH CLEANER FLUID, COULD INTRODUCE ENOUGH LIQUID VOLUME TO HYDRO-LOCK THE ENGINE.

CAUTION: DO NOT USE AIR OR POWER TOOLS FOR SPARK PLUG REMOVAL. SPARK PLUGS MUST ONLY BE REMOVED WITH HAND TOOLS.

5. Tighten, and then loosen the spark plug, working the plug back and forth. Some screeching and high effort may be noticed. The expected removal torque is about 33 ft-lb (45 N.m). Repeat the back and forth turning as needed until turning effort is reduced, and remove the spark plugs.

NOTE: NEW PLUGS SHOULD BE INSTALLED USING A FILM COATING OF MOTORCRAFT Â HIGH TEMPERATURE NICKEL ANTI-SEIZE LUBRICANT ON THE GROUND ELECTRODE SHIELD. DO NOT COAT THE ELECTRODE STRAP. (Fig. 1)

Fig. 1: Anti-Seize Lubricant Application To Ground Electrode Shield

SEPARATED/BROKEN SPARK PLUG REMOVAL

If the spark plug separates after following the Spark Plug Removal Procedure, it will fail in one of three modes. Refer to the appropriate removal procedure as required.

a. Mode 1: The ground electrode shield is left behind as an empty shell. (Fig. 2)

Fig. 2: Ground Electrode Shield Left Behind As Empty Shell

b. Mode 2: The entire porcelain insulator and ground electrode shield remains in the cylinder head. (Fig. 3)

Fig. 3: Entire Porcelain Insulator And Ground Electrode Shield Remains In Cylinder Head

c. Mode 3: The upper section of porcelain broke off with remaining porcelain left inside the ground shield. (Fig. 4)

Fig. 4: Broken Porcelain Remains In Cylinder Head

Fig. 5: Flowchart Of Procedure

Mode 1 Procedure

Use Rotunda special service tool 303-1203 to remove an empty ground electrode shield from the cylinder head. (Fig. 6)

Fig. 6: Rotunda Special Service Tool 303-1203

NOTE: THIS TOOL IS ONLY DESIGNED TO WORK WITH AN EMPTY GROUND ELECTRODE SHIELD. IF PORCELAIN REMAINS, PROCEED TO MODE 2 OR 3 REMOVAL.

1. Modify vacuum cap to a 3/8" (10 mm) length for each ground electrode shield that needs to be removed. (Fig. 7)

Fig. 7: Installing Modified Vacuum Cap

2. Use the installation rod (J) provided with service tool 303-1203 update to install the modified vacuum cap. Push the cap into the ground shield down to the electrode strap. This will plug and protect the combustion chamber from contamination. (Fig. 7)

3. Thread-tap the ground electrode shield using a 9.0 x 1.0 mm plug tap (tap profile is about 3-4 reduced diameter threads on the tip end).

a. Coat the end of the tap with general purpose grease. (Fig. 8)

Fig. 8: Coating Tap With Grease

b. Turn the tap about 3 to 4 turns into the ground electrode shield. Back the tap up frequently to break chips and avoid cut material from coiling-up in the spark plug well. A tap socket adaptor (K) is provided with service tool 303-1203 update to connect the tap to a 3/8" socket drive.

CAUTION: DO NOT ATTEMPT TO REMOVE THE GROUND ELECTRODE SHIELD WITH THE TAP AND WRENCH. THE TAP MAY BREAK IF THIS IS ATTEMPTED.

4. Thread Rotunda special service tool 303-1203 into the ground electrode shield. (Fig. 9)

Fig. 9: Details Of Tool As Installed In Head

a. Install the stepped end of the tool pilot bushing into the spark plug well ensuring it bottoms out.

b. Screw the center shank into the ground electrode shield. Do not over tighten the shank, to prevent thread stripping.

c. Install the nylon washer and jack nut until finger tight.

d. Turn the jack nut until the ground electrode is freed from the cavity and withdraw the tool assembly.

NOTE: NEW PLUGS SHOULD BE INSTALLED USING A FILM COATING OF MOTORCRAFT Â HIGH TEMPERATURE NICKEL ANTI-SEIZE LUBRICANT ON THE GROUND ELECTRODE SHIELD. DO NOT COAT THE ELECTRODE STRAP.

Mode 2 Procedure

1. Add an additional 1/2 teaspoon Motorcraft  Carburetor Tune-Up Cleaner fluid into spark plug well and allow 15 minutes of soak time.

2. Using long-reach nose pliers grasp and remove the porcelain with an up and down motion taking care not to fracture the porcelain.

3. Refer to Mode 1 Procedure to remove the remaining ground electrode shield from the cylinder head.

Mode 3 Procedure

CAUTION: DO NOT DRIVE PORCELAIN DOWN INTO THE GROUND SHIELD WITH A PUNCH AS FRAGMENTS MAY ENTER THE COMBUSTION CHAMBER.

Use Rotunda special service tool kit 303-1398 to remove porcelain broken inside the ground electrode shield. (Fig. 10)

Fig. 10: Rotunda Special Service Tool Kit 303-1398

Porcelain Removal - Preparation

CAUTION: THE ENGINE AND THE BONDING ADHESIVE MUST BE ROOM TEMPERATURE OF 70 °F (21 °C) OR HIGHER FOR PROPER CURE AND BOND STRENGTH. VERIFY EXPIRATION DATE OF ADHESIVE.

CAUTION: DO NOT REUSE PINS. THIS ENSURES THE CORRECT SURFACE CHARACTERISTICS FOR BONDING.

1. Remove any remaining electrode material from broken porcelain with long nose reach pliers.

2. Spray Motorcraft  Metal Brake Parts Cleaner into the porcelain hole for 2-4 seconds using the straw nozzle supplied with the brake cleaner can.

3. Insert a pin (A) into the collet (B). Screw the collet onto the threaded rod (C). Install the assembled collet, pin, and threaded rod into the steel tool pilot (F). (Fig. 11 and Fig. 12 )

Fig. 11: Inserting Pin Into Collet

Fig. 12: Installing Assembled Collet, Pin, And Threaded Rod Into Steel Tool Pilot

4. Retract the collet and pin into the steel tool pilot, protecting the pin. (Fig. 13 and Fig. 14 )

Fig. 13: Retracting Collet And Pin Into Steel Tool Pilot

Fig. 14: Collet And Pin Inside Steel Tool Pilot

NOTE: PIN TIP DAMAGE OR BENT PINS WILL PREVENT INSERTION INTO THE PORCELAIN.

5. Insert the completed assembly into the spark plug well and fully engage the pin into the porcelain. (Fig. 15)

Fig. 15: Inserting Completed Assembly Into Spark Plug Well

6. Spray Motorcraft  Metal Brake Parts Cleaner 2-4 seconds between the spark plug well and steel tool pilot. The steel tool pilot must be lifted up approximately 1/2" to allow brake cleaner to flood the porcelain and pin.

7. Scrub the porcelain inside diameter by moving the threaded rod up and down vigorously. Take care making sure the pin does not disengage the porcelain. (Fig. 16).

Fig. 16: Scrubbing Porcelain Inside Diameter

8. Repeat Steps 6 and 7.

9. Remove the tool assembly. Again flood the porcelain with Motorcraft  Metal Brake Parts Cleaner for 2-4 seconds, then blow out the entire spark plug well and porcelain with dry compressed air.

NOTE: CLEAN AND DRY COMPONENTS ARE KEY TO BONDING THE PIN TO THE PORCELAIN.

10. Repeat Steps 1-9 to prepare remaining porcelain fragments as needed.

11. Disassemble the collet and pin from the threaded rod. Dry the tools thoroughly with dry compressed air.

Porcelain Removal - Bonding Process

CAUTION: USE CARE TO PREVENT BONDING AGENT FROM CONTACTING THREADS IN CYLINDER HEAD.

NOTE: WORKING TIME LIMIT OF LOCTITE  638à † RETAINING COMPOUND IS 5 MINUTES.

1. Apply two 3/4" (19 mm) long stripes of Loctite  638à † to opposite sides of a clean and dry applicator (H). Excessive amounts of Loctite  638à † are being used if it drips off the applicator. (Fig. 17)

Fig. 17: Bead Of Loctite  On Applicator

2. Insert applicator into the porcelain and move applicator up and down 1/2" (13 mm) while turning to spread the Loctite  638à † on the inside of the porcelain. (Fig. 18).

Fig. 18: Spreading Loctite  On Inside Of Porcelain

3. Add additional Loctite  638à † , repeating Steps 1 and 2.

4. Clean the applicator with Motorcraft  Metal Brake Parts Cleaner before the bonding agent starts to cure.

5. Reassemble a dry and clean collet and pin assembly.

6. Apply two 3/4" (19 mm) long stripes of Loctite  638à † to the pin. Excessive amounts of Loctite  638à † are being used if it drips off the pin.

7. Retract the collet and pin into the steel tool pilot to protect the Loctite  638à † coated pin.

8. Insert the completed assembly into spark plug well and fully engage the pin into the porcelain with a twisting motion to spread the bonding agent.

9. Add additional Loctite  638à † , repeating Steps 6-8.

10. Leave the pin fully inserted in the porcelain while the adhesive cures. Replace the steel tool pilot with the aluminum alignment sleeve (G), Fig. 9, to support the threaded rod while the adhesive cures if additional porcelain fragments are present in other cylinders. (Fig. 19).

Fig. 19: Alignment Sleeve Installation

CAUTION: A MINIMUM 1 HOUR CURING TIME AT 70 °F (21 °C) DEGREES IS REQUIRED BEFORE EXTRACTION IS ATTEMPTED.

11. Allow the Loctite  638à † to cure for a minimum of one hour at 70 °F (21 °C).

12. Repeat the bonding process for remaining cylinders as needed.

Porcelain Removal - Extraction

1. After a minimum of one hour curing at 70 °F (21 °C), install the steel pilot tool over the threaded rod.

2. Install the washer and jack nut until finger tight against the tool pilot bushing.

CAUTION: ONLY THE STEEL PILOT TOOL IS ACCEPTABLE FOR USE IN PORCELAIN REMOVAL.

3. While holding the end of the threaded rod with a wrench, tighten the jack nut until the porcelain is free of the ground electrode.

4. Refer to Mode 1 Procedure to remove the remaining ground electrode shield from the cylinder head.

NOTE: NEW PLUGS SHOULD BE INSTALLED USING A FILM COATING OF MOTORCRAFT Â HIGH TEMPERATURE NICKEL ANTI-SEIZE LUBRICANT ON THE GROUND ELECTRODE SHIELD. DO NOT COAT THE ELECTRODE STRAP. (Fig. 1)

Porcelain Removal - Pin Slipped Out

In the unlikely event that the pin does not remove the broken porcelain, this process can be repeated. Key elements to success are:

"Â Clean and dry porcelain

" Sufficient Loctite  638à † Retaining Compound spread uniformly

" Loctite  638à † cure time and temperature

"Â Preventing the threaded rod from rotating while removing the porcelain

Replacement Supplies

Replacement kit components and additional kit consumables (Loctite  638à † Retaining Compound and pins) can be obtained by calling 1-800-ROTUNDA, Option 5.

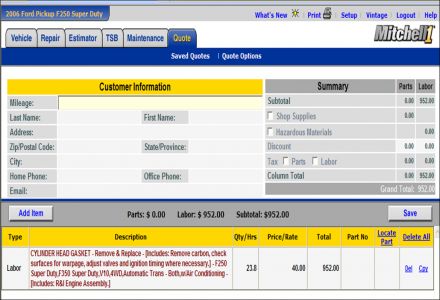

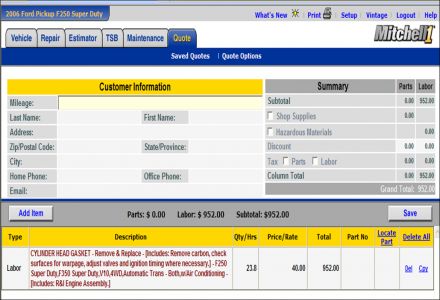

If the heads do need to be removed, I think 4000 is way too much. I have attached an estimate of the removal and installation of the heads.

SPONSORED LINKS

Sunday, March 15th, 2009 AT 10:50 PM