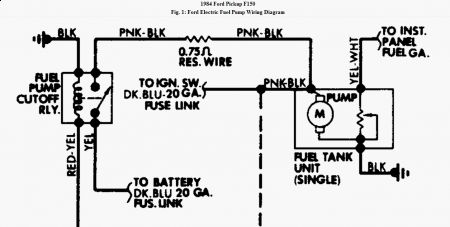

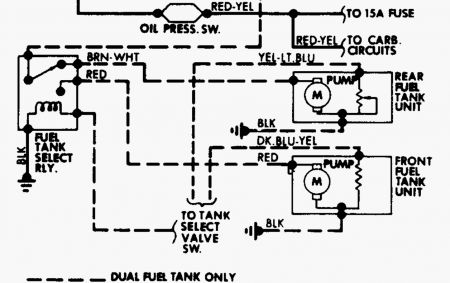

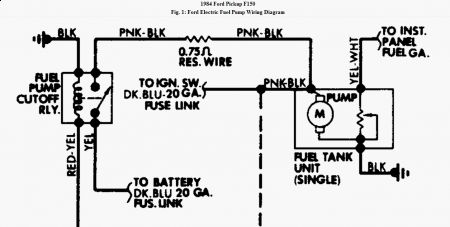

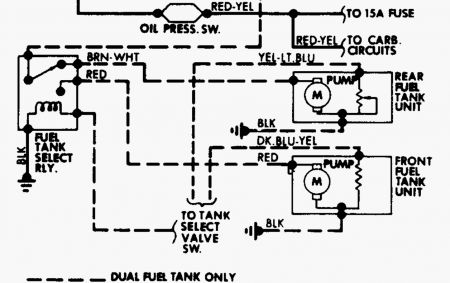

Did you change the oil pump? Prime it right? Here's the electrical wiring diagram.

ELECTRICAL CONTINUITY 1. Check fuel tank for adequate fuel supply. Check for leaks at all lines and fittings. Disconnect connector to fuel pump just forward of fuel tank. Connect a voltmeter to body wiring harness connector. 2. Turn ignition "ON". Battery voltage should be present, voltage should return to zero after approximately 1 second. Turn ignition switch momentarily to "START". Voltage should be approximately 8 volts while cranking. If voltage is not within specifications, check electrical system. Fig. 1: Ford Electric Fuel Pump Wiring Diagram FUEL PUMP OPERATION 1. Disconnect fuel return line at throttle body. Connect hose from throttle body fitting to a calibrated container of at least 1 quart capacity. Connect pressure gauge (T80L 9974 A) to fuel diagnostic valve on fuel charging assembly. 2. Disconnect connector to fuel pump just forward of fuel tank. Connect an auxiliary wiring harness to fuel pump. Energize pump for 10 seconds by connecting harness to a fully charged 12 volt battery. If fuel pump does not run, check connection at fuel pump. 3. Fuel pump is operating properly if fuel pressure is 35-45 psi (2.5-3.2 kg/cm 2 ) and if fuel flow is a minimum of 10 ounces. Fuel pump must maintain a minimum of 30 psi (2.1 kg/cm 2 ) immediately after de-energization. If all 3 conditions are met, fuel pump is operating properly. Check for engine and electrical problems. 4. If pressure conditions are met but flow is not, check for blocked filter(s) and lines. After correcting blockage, retest fuel pump. If flow is still not met, replace fuel pump. If fuel flow is met but pressure is not, check for worn or damaged pressure regulator valve on throttle body. 5. If both pressure and flow conditions are met but pressure cannot be maintained after de- energization, check for leaking injector valve(s), and/or pressure regulator valve. If both check okay, replace fuel pump. INERTIA SWITCH In the event of a collision, contacts in inertia switch will open and shut fuel pump off. The fuel pump will shut off even if engine continues to run, engine will stop after fuel pump is off. It is not possible to restart engine until inertia switch is manually reset. The inertia switch is located behind instrument panel. To reset inertia switch, depress button on top of inertia switch. Page 1 of 1 3/11/2010 ...

I dont the the pressure spec is right for carb models, should probably be about 9-13 psi?

SPONSORED LINKS

Thursday, March 11th, 2010 AT 3:56 PM