Hi,

That is one I don't know off the top of my head. The manual doesn't provide that info, but usually those are around a T35.

___________________________

I don't know if you need them, but here are the directions for the 93 upper and lower intake removal and replacement. It includes torque specs. The attached pics correlate with the directions.

__________________________

1993 Ford Truck F 150 2WD Pickup V8-302 5.0L

Upper

Vehicle Engine, Cooling and Exhaust Engine Intake Manifold Service and Repair Procedures Upper

UPPER

WARNING: DO NOT SMOKE, CARRY LIGHTED TOBACCO OR OPEN FLAME OF ANY TYPE WHEN WORKING ON OR NEAR ANY FUEL-RELATED COMPONENT, HIGHLY FLAMMABLE MIXTURES ARE ALWAYS PRESENT AND MAY BE IGNITED, RESULTING IN POSSIBLE PERSONAL INJURY.

Upper Intake Manifold and Throttle Body

Removal

1. Disconnect electrical connectors at idle air control valve, throttle position sensor and EGR position sensor.

2. Disconnect throttle linkage at throttle ball. Disconnect AOD (5.0L only) or C6 (5.8L only) transmission linkage from throttle body. Remove two bolts securing throttle linkage bracket to intake. Position bracket with cables out of way.

CAUTION: When disconnecting throttle cable from ball stud, use a screwdriver or similar tool close to the stud and pry slowly. Pulling by hand may damage the cable.

3. Disconnect upper intake manifold vacuum fitting connections by disconnecting all vacuum lines to vacuum tree, vacuum lines to EGR valve and vacuum line to fuel pressure regulator.

4. Disconnect PCV system by disconnecting hose from fitting on rear of upper manifold.

5. On Econoline models, remove the oil fill tube.

6. Remove canister purge line(s) from fitting(s) on throttle body.

7. Disconnect water heater lines from the throttle body.

8. Disconnect EGR tube from EGR valve by removing flange nut.

9. Remove bolt from upper intake support bracket to upper manifold.

10. Remove six upper intake manifold retaining bolts.

11. Remove upper intake and throttle body as an assembly from lower intake manifold.

Installation

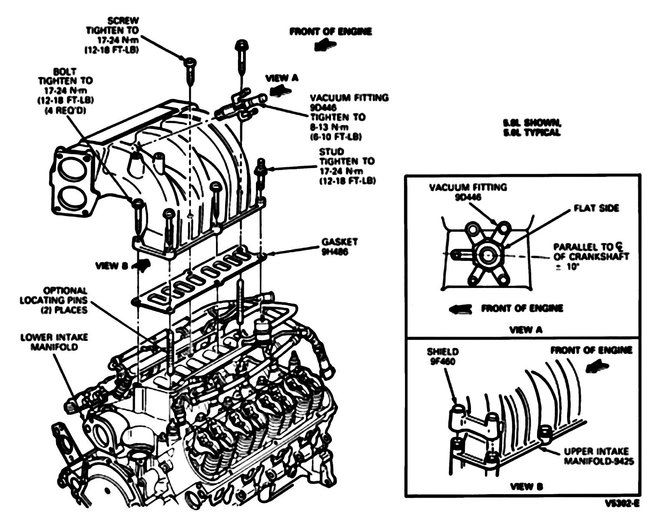

1. Clean and inspect the mounting faces of the lower and upper intake manifolds.

2. Position new gasket on lower intake mounting face. The use of alignment studs may be helpful.

3. Install upper intake manifold and throttle body assembly to lower manifold making sure gasket remains in place (if alignment studs are not used).

4. Install six upper intake manifold retaining bolts and tighten to 17-24 Nm (12-18 ft-lb).

5. Install upper intake support bracket to upper manifold attaching bolt.

6. Install EGR tube. Tighten flange nuts to 34-47 Nm (25-35 ft-lb).

7. Install canister purge lines to fittings on throttle body.

8. Connect water heater lines to the throttle body.

9. Connect PCV hose to rear of upper manifold.

10. Install oil fill tube (Econoline models).

11. Connect vacuum lines to vacuum tree, EGR valve and fuel pressure regulator.

12. Position throttle linkage bracket with cables to upper intake manifold. Install two retaining bolts and tighten to 11-13 Nm (8-10 ft-lb). Connect throttle cable and transmission cable to throttle body.

13. Connect electrical connectors at idle air control valve, TP sensor and EGR position sensor.

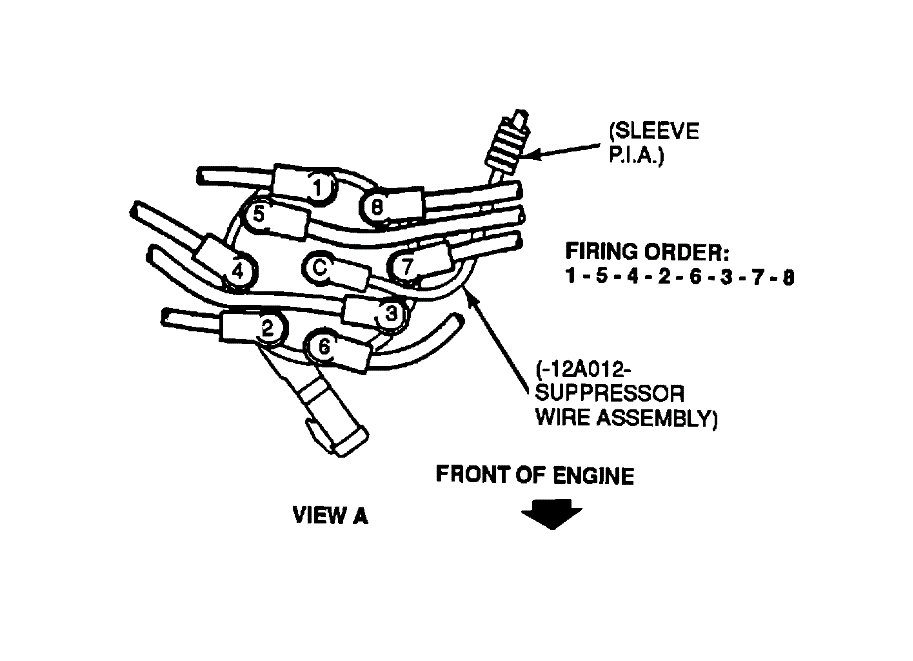

Pic 1

_____________________________________

1993 Ford Truck F 150 2WD Pickup V8-302 5.0L

Lower

Vehicle Engine, Cooling and Exhaust Engine Intake Manifold Service and Repair Procedures Lower

LOWER

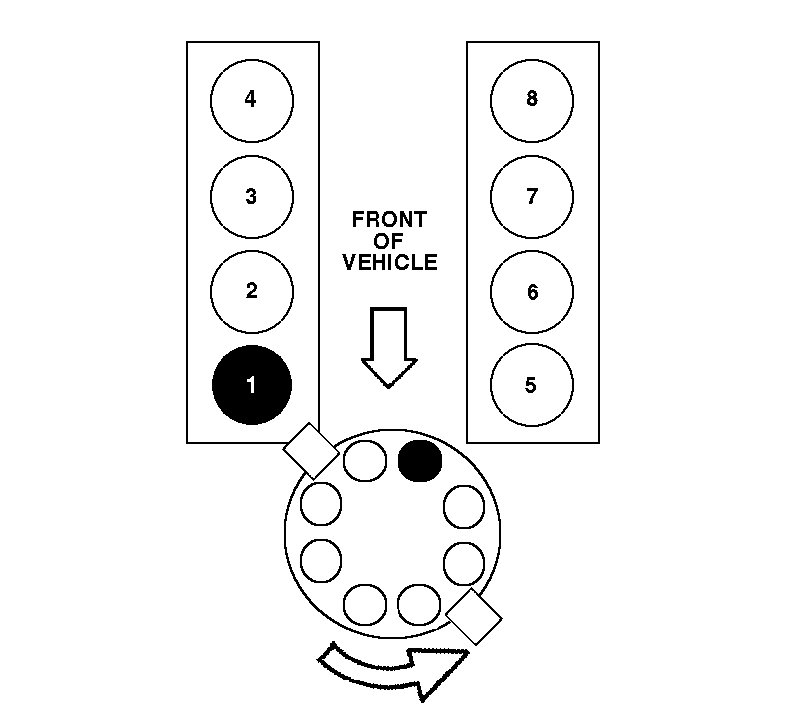

1. Drain cooling system, then remove air cleaner with intake duct assembly and crankcase ventilation hose.

2. Disconnect accelerator cable and speed control linkage (if equipped) from carburetor or throttle body. Remove accelerator cable bracket, then disconnect kickdown rod from carburetor or throttle body on models equipped with automatic transmission. Disconnect electric choke, carburetor solenoid electrical connectors or EEC connector, if equipped.

3. Disconnect high tension lead and wires from ignition coil.

4. Disconnect ignition wires from spark plugs, then remove wires and bracket assembly from rocker arm cover attaching stud.

5. Remove distributor cap and ignition wires as an assembly.

6. Disconnect fuel inlet line from carburetor or throttle body.

7. Disconnect vacuum hoses from distributor, then remove distributor and disconnect evaporative hoses, if equipped.

8. Disconnect upper radiator hose from coolant outlet housing.

9. Disconnect electrical connector from coolant temperature sending unit, then remove heater hose from intake manifold.

10. Remove water pump bypass hose from coolant outlet housing, then disconnect crankcase vent hose from rocker arm cover.

11. Remove intake manifold attaching bolts, then the intake manifold and carburetor as an assembly. On models with EFI remove manifold as follows:

a. Remove upper intake manifold and throttle body as an assembly.

B. Remove lower intake manifold assembly.

C. It may be necessary to carefully pry the intake manifold from the cylinder heads. Remove manifold gaskets and seals and discard intake manifold attaching bolt sealing washer.

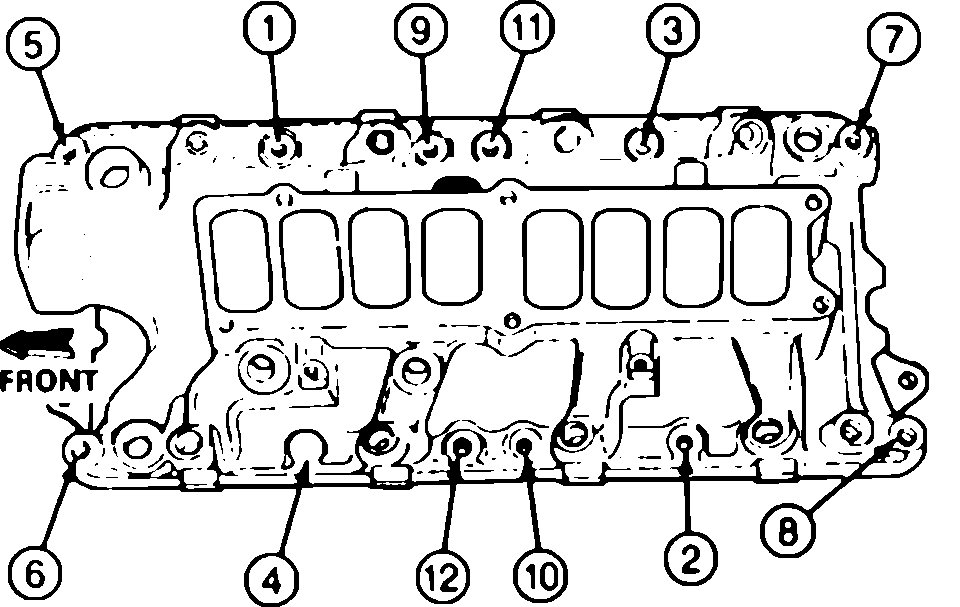

Fig. 13 Intake manifold installation

Pic 2

Fig. 14 Intake manifold bolt tightening sequence

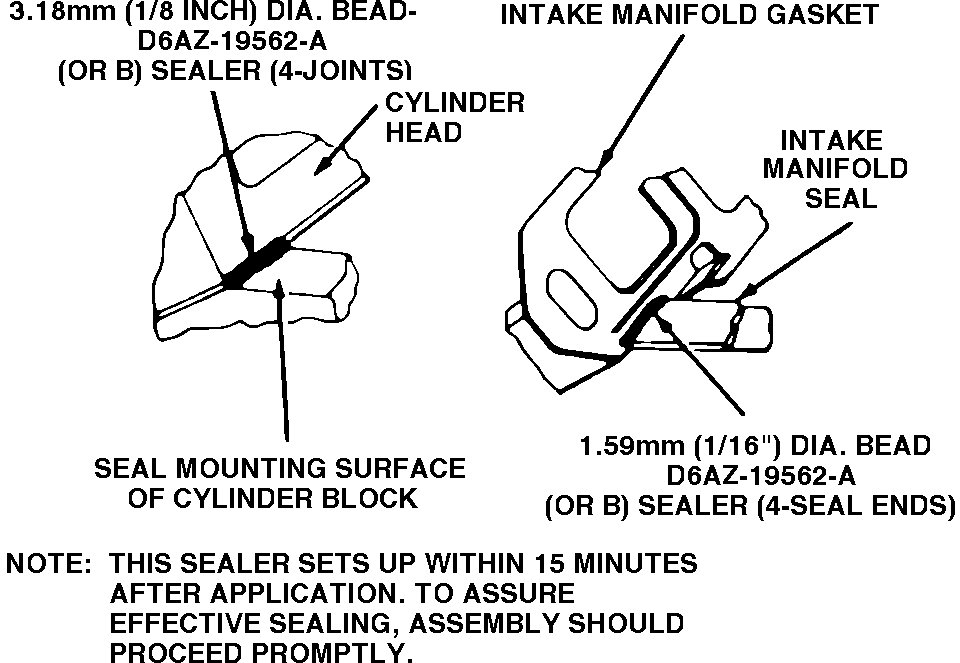

pic 3

12. Reverse procedure to install. Apply sealer as shown in Fig. 13. Tighten manifold attaching bolts to specifications in sequence shown in Fig. 14.

_________________________

Hope that helps. Let me know if you have other questions.

Joe

Images (Click to make bigger)

Tuesday, February 9th, 2021 AT 2:27 PM

(Merged)