Hello jeepmanjr

On Behalf of 2carpros, I wish you happy new year.

When an engine suddenly quits running, but then starts again and runs few seconds and quits running again ,the cause may be the loss of an important sensor signal such as the ignition trigger signal (engines with distributors)

Older GM HEI ignition modules also were prone to this disorder - especially if someone replaced the module in the distributor and forgot to apply the heat sink grease underneath to prevent the module from overheating.

your engine is a 4.3 L I believe and please correct me if I'm wrong so we can be on the right path.

Here is what we can do

start with ignition coil.

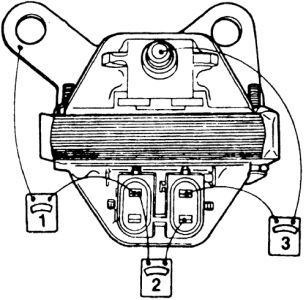

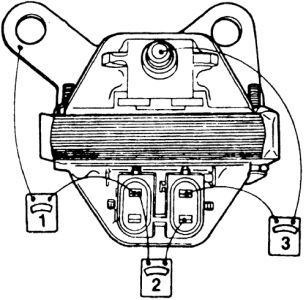

Disconnect the distributor lead and wiring from the coil.

Set the ohmmeter to the HIGH scale, then connect it to the coil as shown in Step 1 of the illustration. The reading should be infinite. If not, verify a proper test connection to be assured of a true test result and if still not infinite, replace the coil.

Set the ohmmeter to the LOW scale, then connect it as shown in Step 2 of the illustration. The reading should be very low or zero. If not, verify a proper test connection and replace the coil.

Set the ohmmeter on the HIGH scale, then connect it to the coil as shown in Step 3 of the illustration. The ohmmeter should NOT read infinite. If it does, verify the connection and replace the coil.

Reconnect the distributor lead and wiring to the coil.

print this for your diagnosis.

pick up coil testing

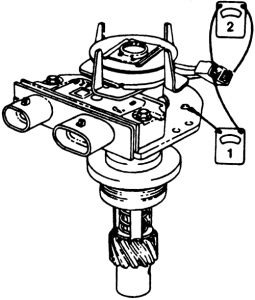

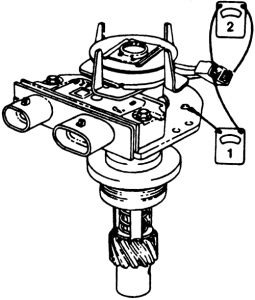

Disconnect the negative battery cable.

Remove the distributor cap and disconnect the pick-up coil connector from the module

Connect an ohmmeter to either pick-up coil lead and the housing as shown in Step 1 of the illustration. The reading should NOT be infinite. If the reading is infinite, replace the coil.

Connect an ohmmeter to both pick-up coil leads as shown in step 2 of the illustration. Flex the wires by hand at the coil and the connector to locate an intermittent opens.

The ohmmeter should read a constant number in the 500-1500- range. If not, replace the pick-up coil.

print this for your diagnosis

Friday, January 29th, 2021 AT 11:02 AM

(Merged)