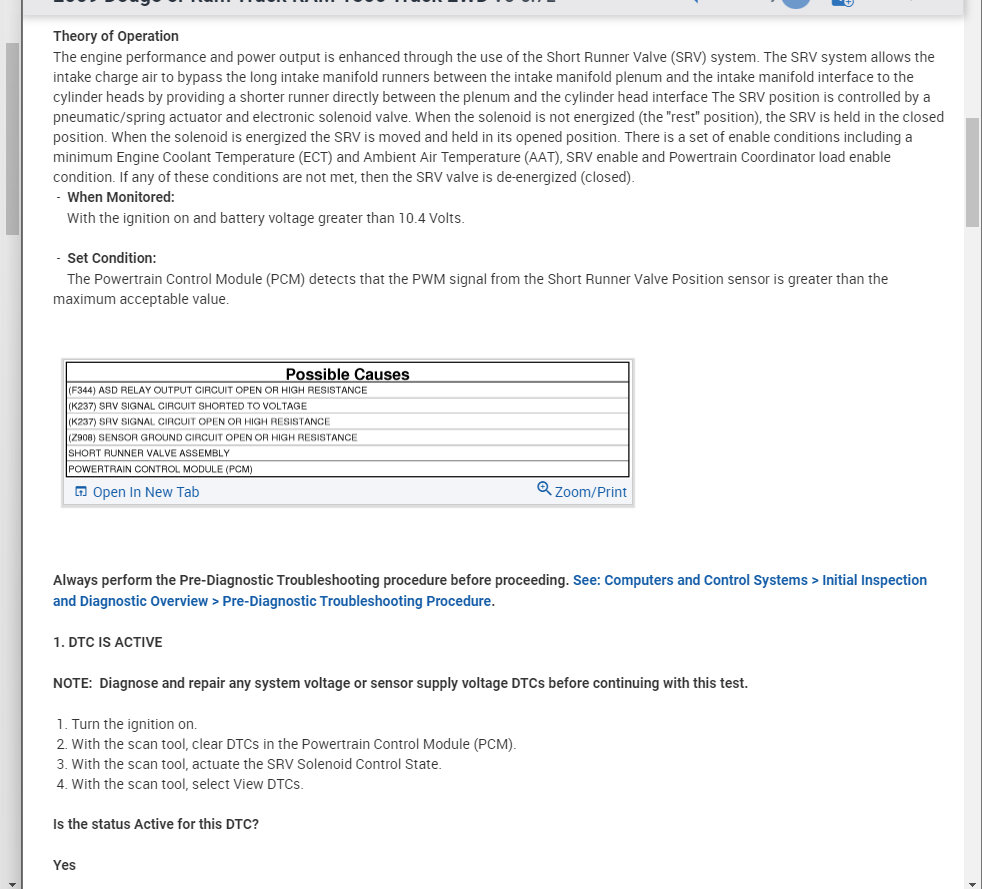

There are a couple things that will cause this, so we are going to have to run through this testing. This is going to require some electrical testing. so, here are a couple of guides that will help with this:

https://www.2carpros.com/articles/how-to-use-a-voltmeter

https://www.2carpros.com/articles/how-to-check-wiring

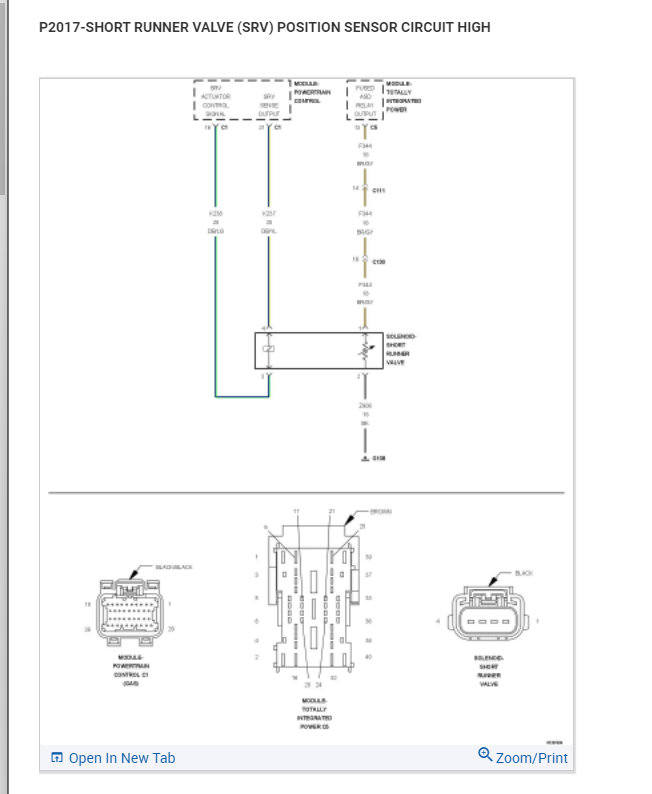

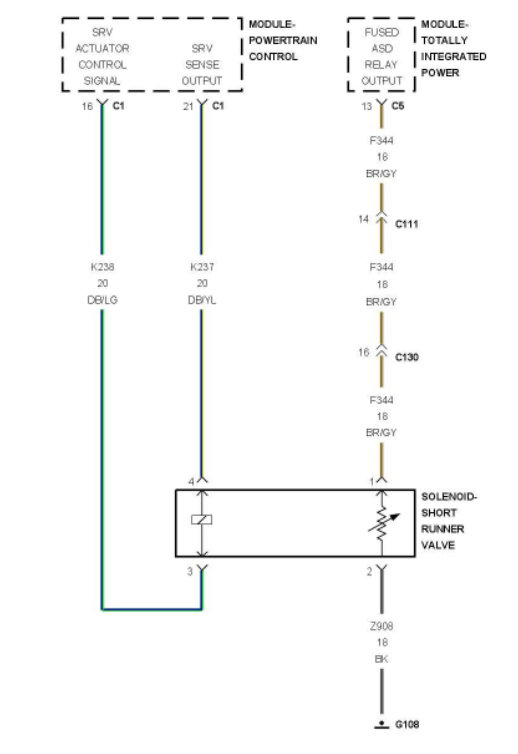

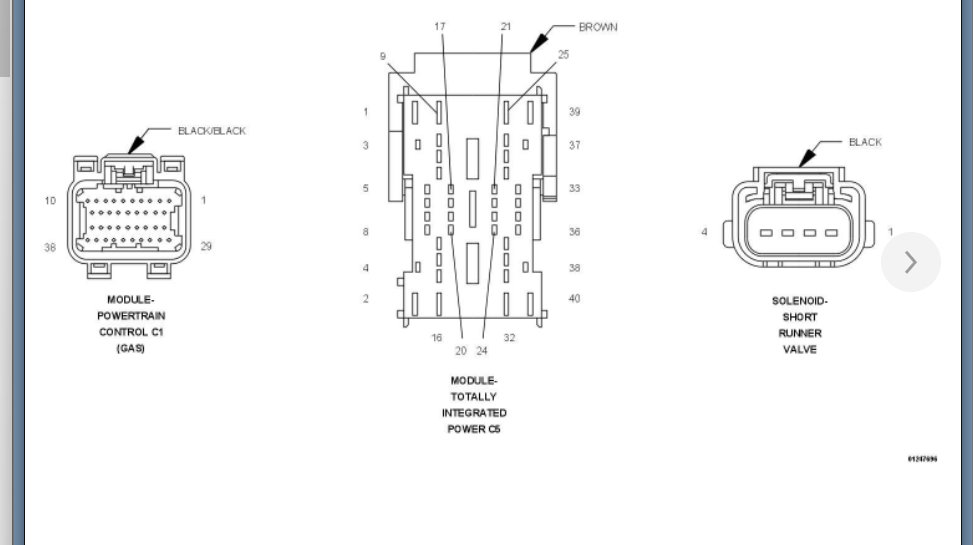

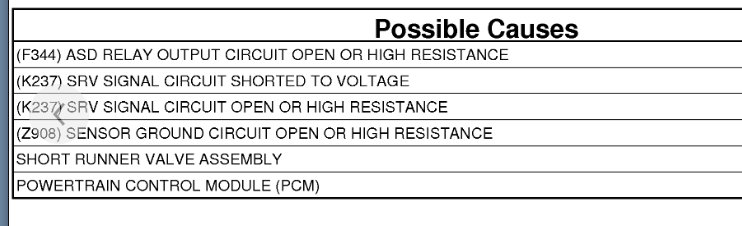

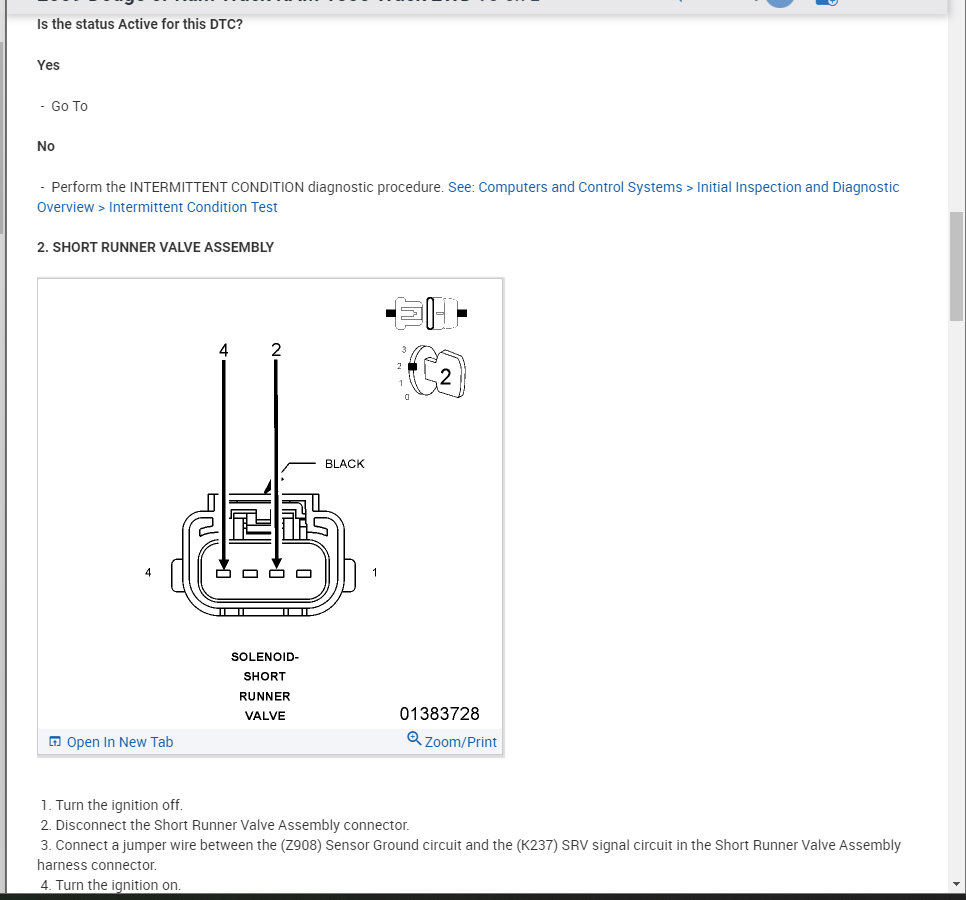

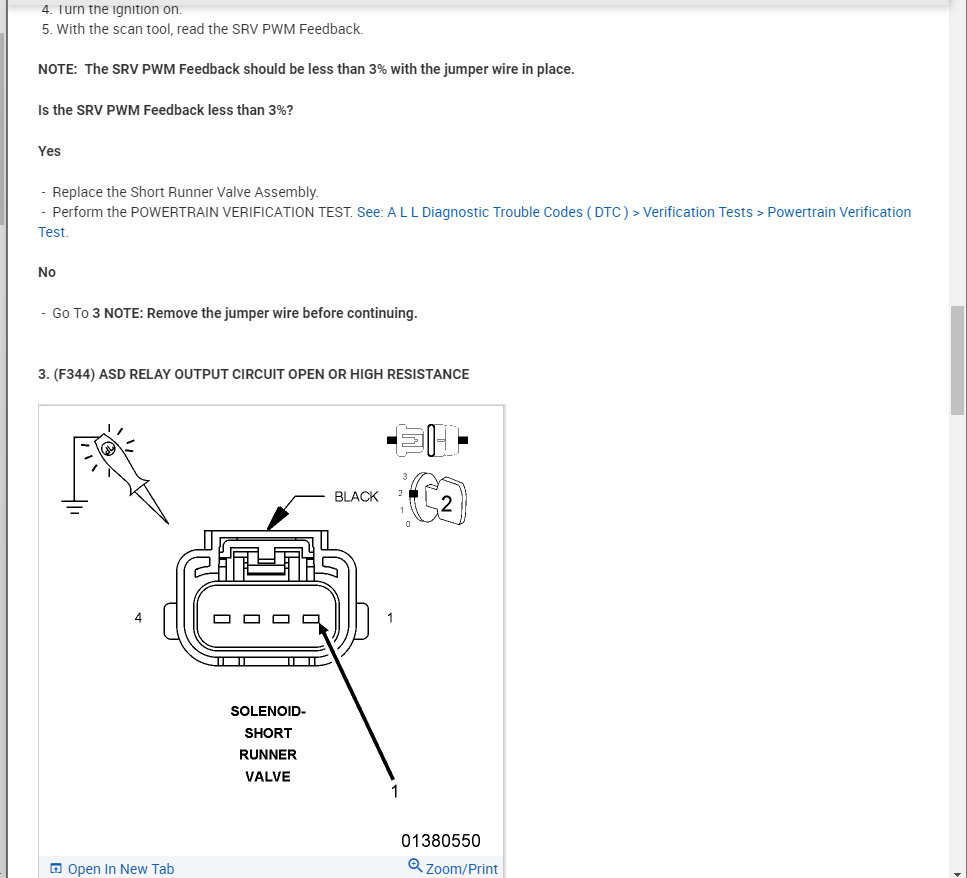

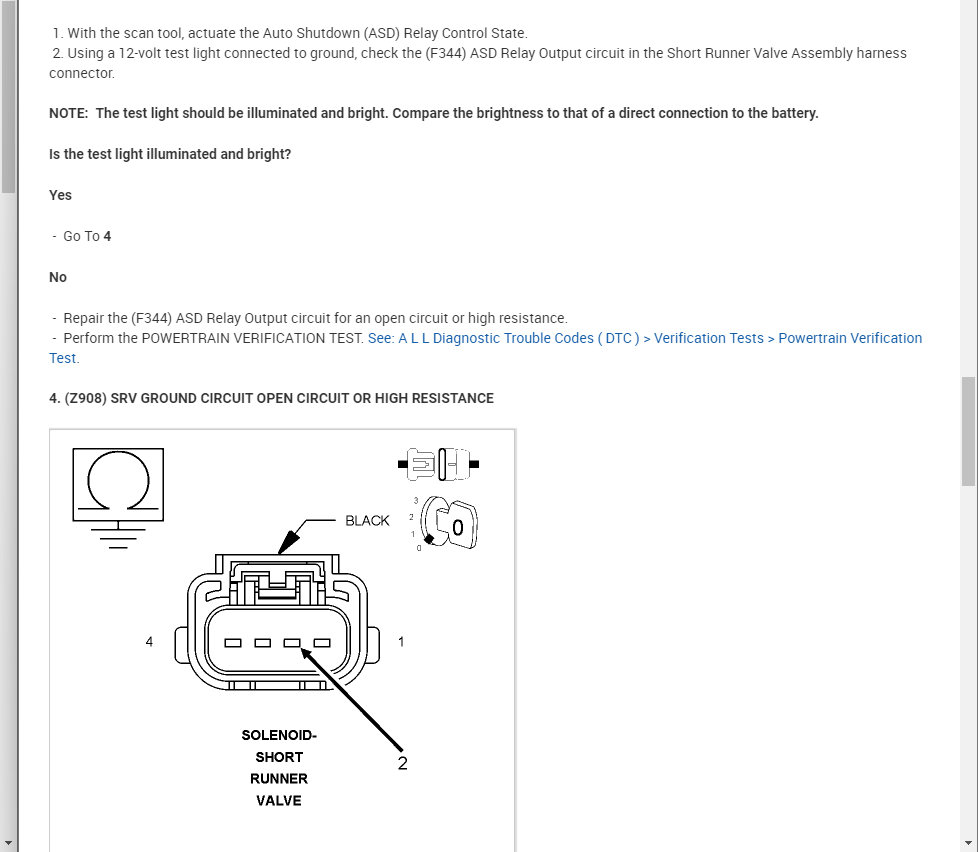

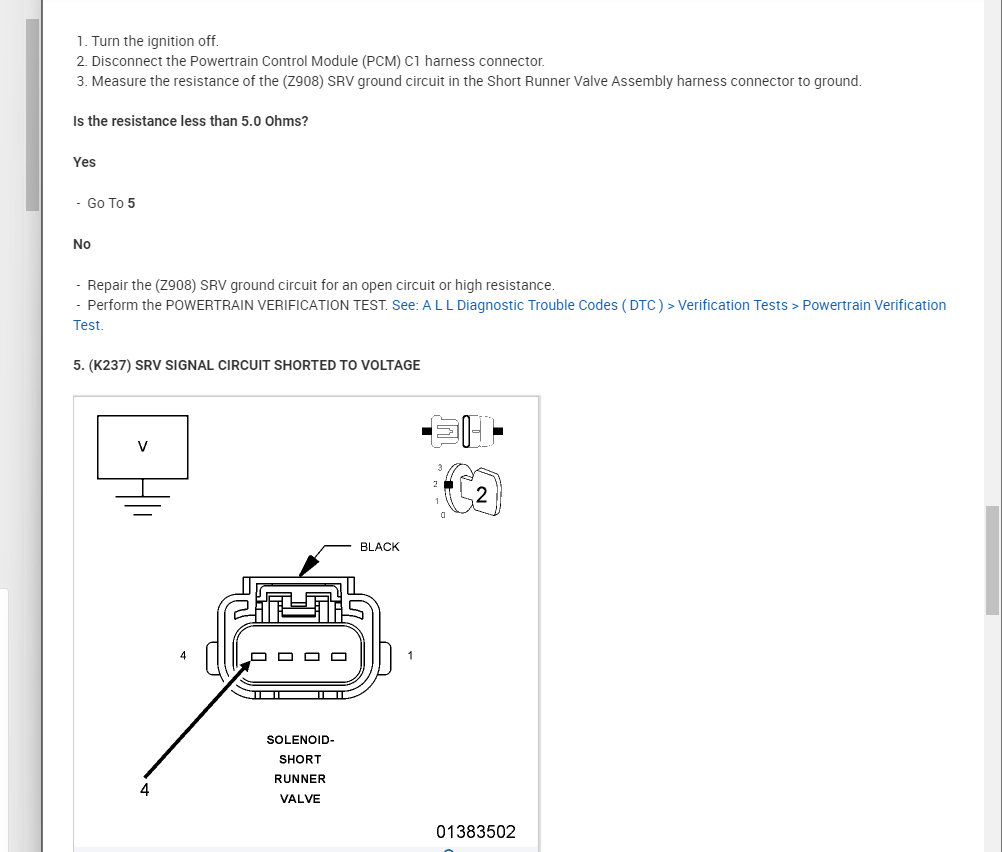

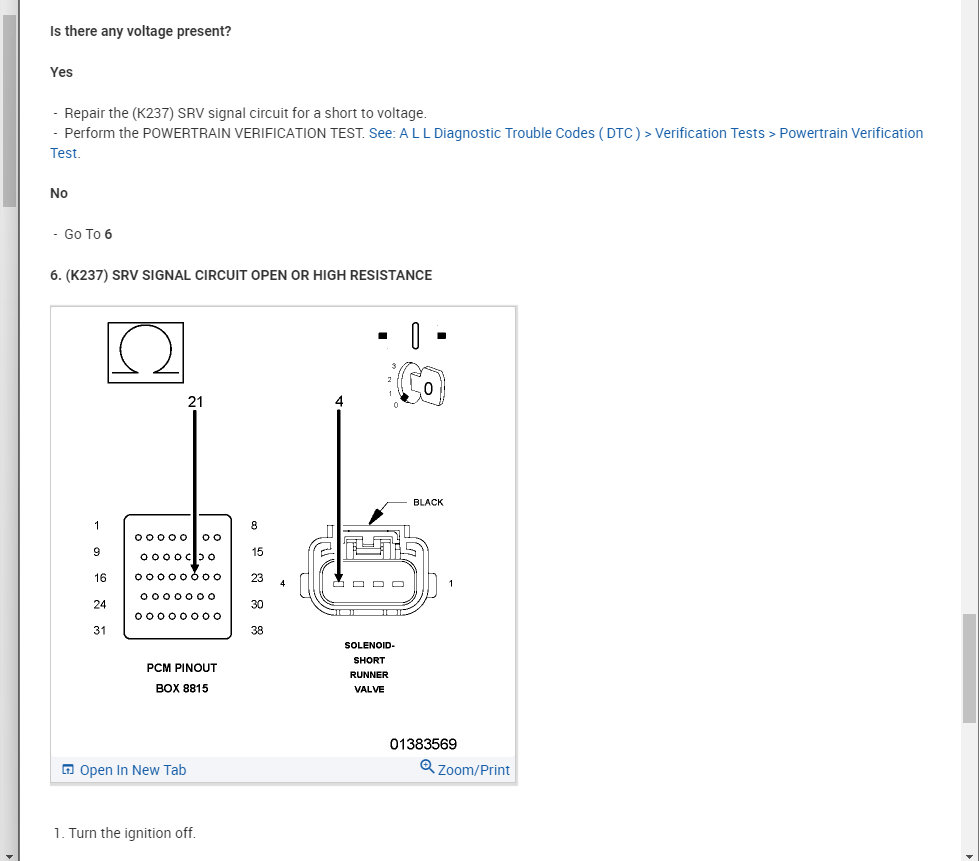

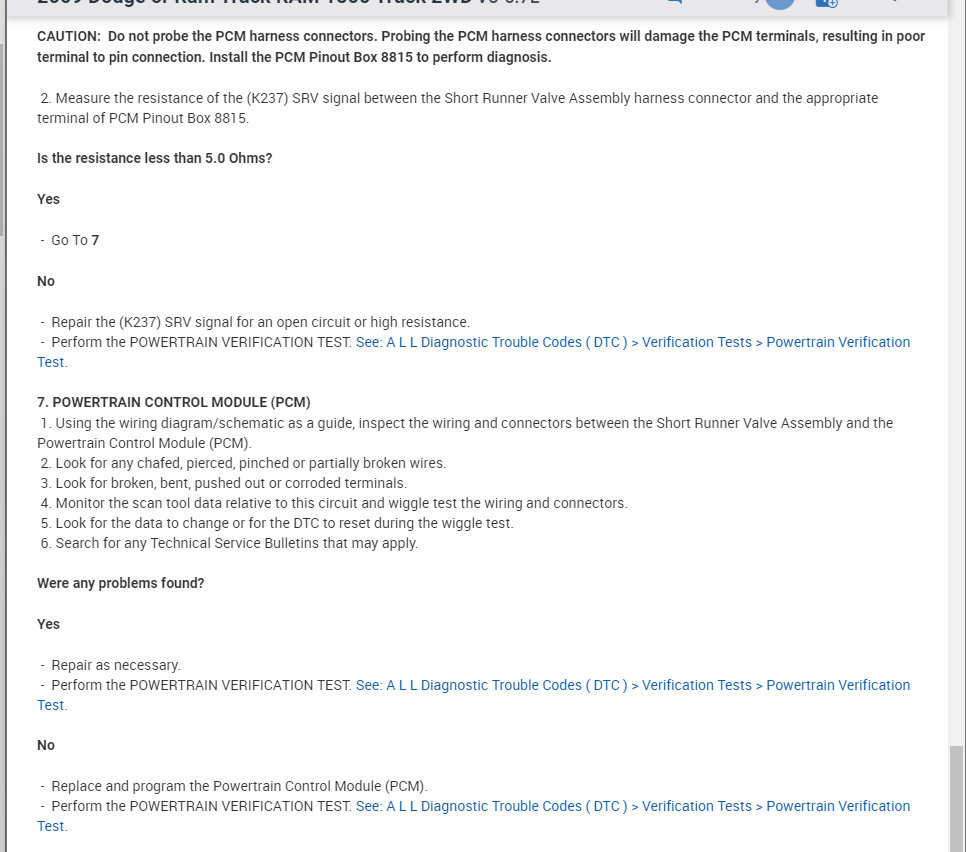

Please see the info below on this code. I suspect you have a possible wiring issue or the PCM is the issue as these are the most common causes of this.

Let me know what questions you have, and we can go from there.

Thanks

Images (Click to make bigger)

SPONSORED LINKS

Monday, May 9th, 2022 AT 7:38 PM