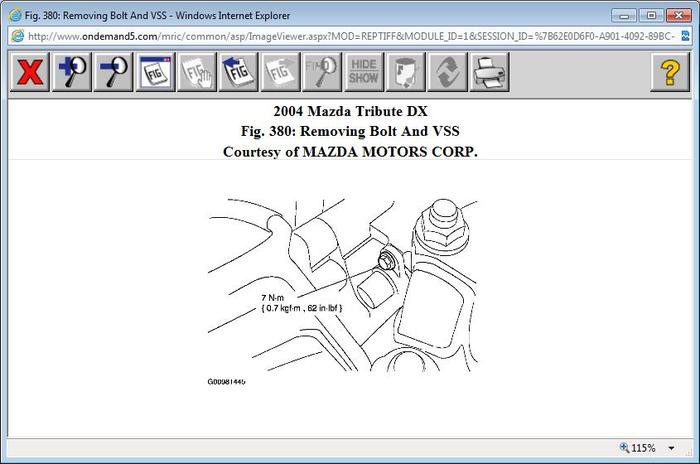

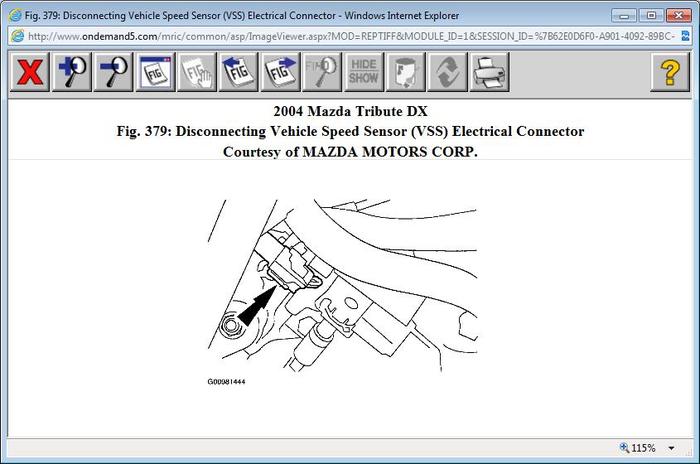

I have 12 volts at coil. I decided to remove and inspect crank sensor on the transmission side of the engine ( on engine below thermostat housing bolted to engine block) once I removed it I noticed the tip of the sensor was broken, yes, broken. So I knew I found the problem.

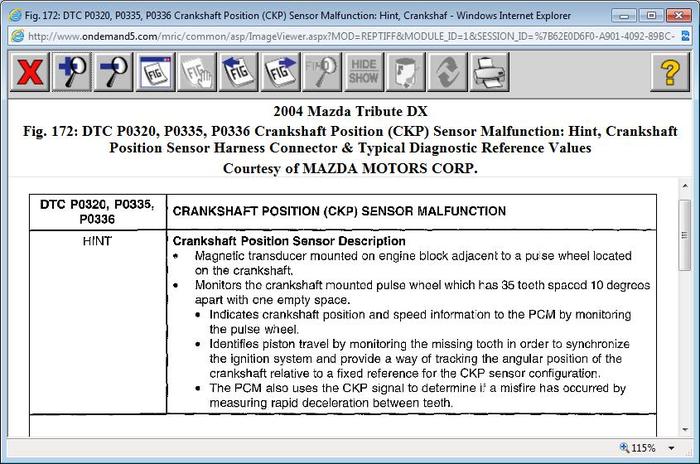

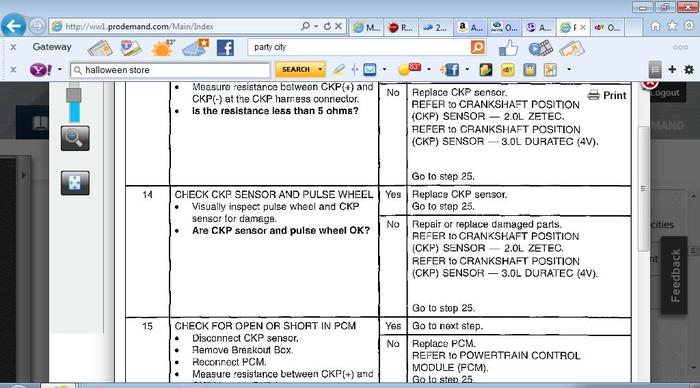

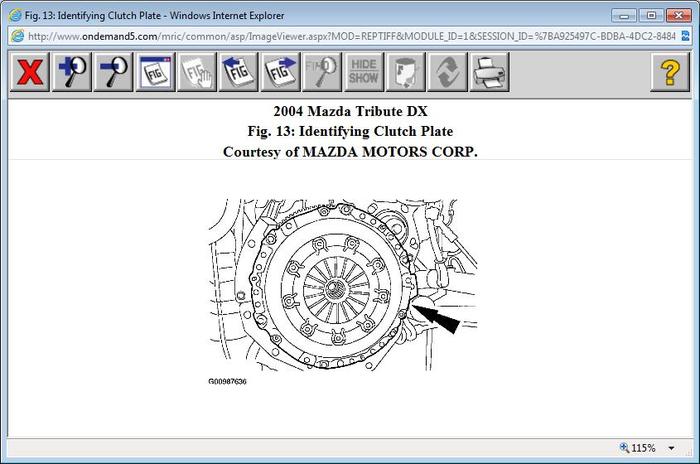

I put a new crank sensor in and the car started but ran for 1 hour idling as if a cylinder was not firing. Then it would not start ever again. I removed my brand new replacement sensor to find the tip was rubbed off enough to see the inside metal. I think it could be a possible warped flywheel but I am having trouble finding diagrams of the excitation part of how the crank position sensor works.

i believe the flywheel has holes that excite the sensor. The tribute does move and clutch works for the hour I had it running, so the manual trans does work as well as the clutch

SPONSORED LINKS

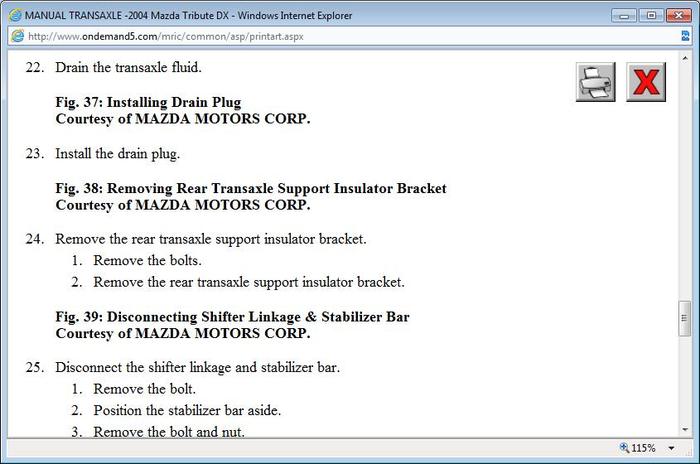

Friday, July 13th, 2012 AT 8:13 PM